Corrosion-resistant PE composite material for septic tank and preparation method of corrosion-resistant PE composite material

A composite material and corrosion-resistant technology, which is applied in the field of polyethylene materials, can solve the problems of septic tank leakage, polluted urban underground water supply pipes, and tilted buildings, and achieves good corrosion resistance and abrasion resistance, and enhances compatibility. , the effect of reducing the surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

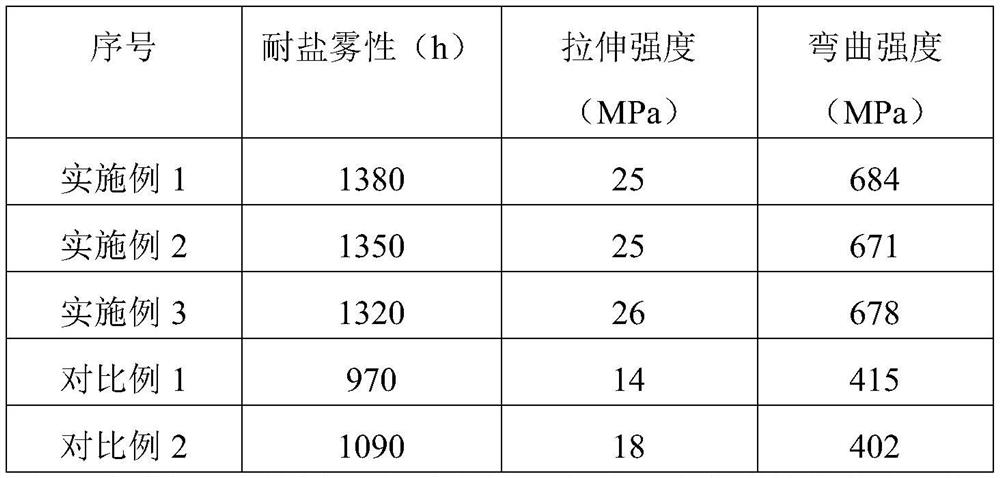

Examples

Embodiment 1

[0021] A preparation method of a corrosion-resistant PE composite material for septic tanks, comprising the following steps:

[0022] S1: Put 45 parts of linear low density polyethylene, 18 parts of polyethylene glycol gel powder, 2 parts of dibutyl phthalate, 2 parts of polyethylene wax and 2 parts of pentaerythritol tetrapropionate into a high-speed mixer Mix for 4-6min to obtain a mixture of components;

[0023] S2: Add the above-mentioned component mixture from the hopper to the twin-screw extruder, melt, extrude, cool, shape and slice through the twin-screw extruder to obtain a corrosion-resistant PE composite material;

[0024] Among them, the twin-screw extruder is divided into 4 zones for processing temperature:

[0025] The temperature of the first zone is 200-230°C, the temperature of the second zone is 250-300°C, the temperature of the third zone is 250-300°C, the temperature of the fourth zone is 280-320°C, the nozzle temperature is 400°C, and the mold temperature...

Embodiment 2

[0030] A preparation method of a corrosion-resistant PE composite material for septic tanks, comprising the following steps:

[0031] S1: Put 40 parts of linear low density polyethylene, 15 parts of polyethylene glycol gel powder, 1 part of dibutyl phthalate, 1 part of polyethylene wax and 1 part of pentaerythritol tetrapropionate into a high-speed mixer Mix for 4-6min to obtain a mixture of components;

[0032] S2: Add the above-mentioned component mixture from the hopper to the twin-screw extruder, melt, extrude, cool, shape and slice through the twin-screw extruder to obtain a corrosion-resistant PE composite material;

[0033] Among them, the twin-screw extruder is divided into 4 zones for processing temperature:

[0034] The temperature of the first zone is 200-230°C, the temperature of the second zone is 250-300°C, the temperature of the third zone is 250-300°C, the temperature of the fourth zone is 280-320°C, the nozzle temperature is 400°C, and the mold temperature is...

Embodiment 3

[0039] A preparation method of a corrosion-resistant PE composite material for septic tanks, comprising the following steps:

[0040] S1: Put 50 parts of linear low density polyethylene, 20 parts of polyethylene glycol gel powder, 3 parts of dibutyl phthalate, 3 parts of polyethylene wax and 3 parts of pentaerythritol tetrapropionate into a high-speed mixer Mix for 4-6min to obtain a mixture of components;

[0041] S2: Add the above-mentioned component mixture from the hopper to the twin-screw extruder, melt, extrude, cool, shape and slice through the twin-screw extruder to obtain a corrosion-resistant PE composite material;

[0042] Among them, the twin-screw extruder is divided into 4 zones for processing temperature:

[0043] The temperature of the first zone is 200-230°C, the temperature of the second zone is 250-300°C, the temperature of the third zone is 250-300°C, the temperature of the fourth zone is 280-320°C, the nozzle temperature is 400°C, and the mold temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com