Method for drawing aluminum conductor

A technology of aluminum conductors and drawing dies, which is applied in the manufacture of cables/conductors, rods/rods/wires/strip conductors, electrical components, etc., can solve the problems of increasing equipment and processes, unfavorable production costs, etc., so as to reduce the failure rate , No waste of raw materials, the effect of slow processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

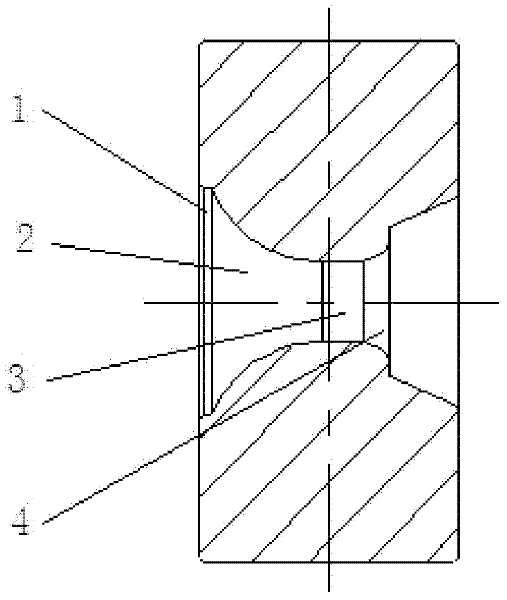

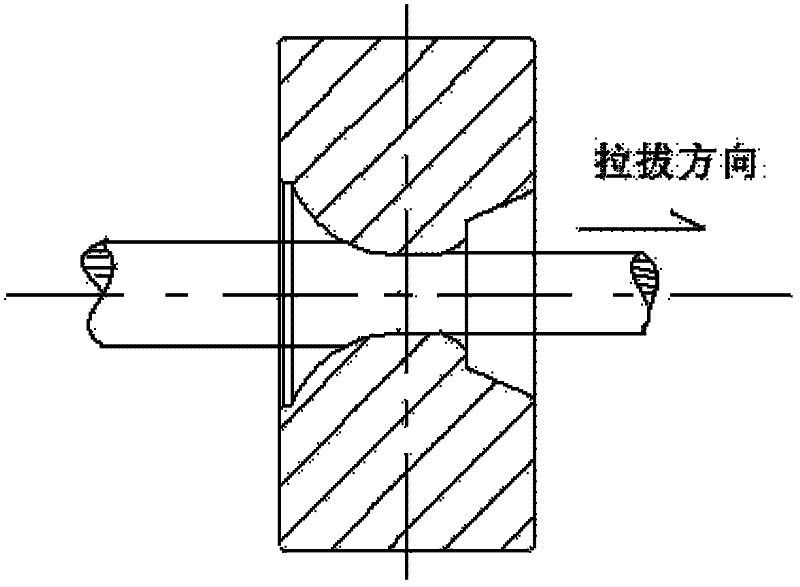

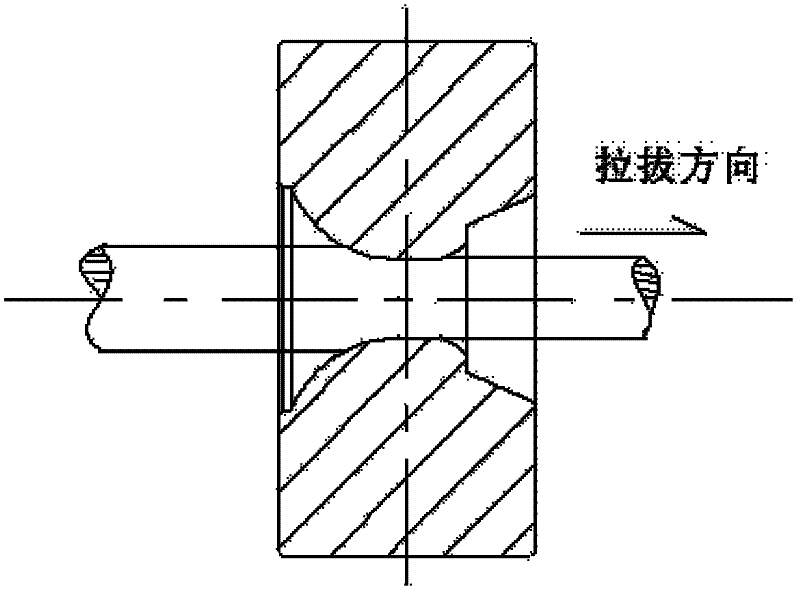

[0035] The circular stranded unpressed aluminum conductor (cross-sectional area 70.2mm 2 ) enter the drawing die from the drawing die entrance area 1, after passing through the die, set the compression coefficient of the drawn aluminum conductor to 0.89, turn on the drawing machine, and under the action of the drum, the aluminum conductor passes through the working area 2, sizing Zone 3 and exit zone 4 are pulled out horizontally from exit zone 4 to form a compact aluminum conductor with rounded cross-section and smooth surface (cross-sectional area 65.5mm 2 ). The material of the die used is diamond, the section of the sizing area 3 is a full circle with a diameter of 9.45 mm, and the inner surface is treated with a mirror surface.

Embodiment 2

[0037] The circular stranded unpressed aluminum conductor (cross-sectional area 24.9mm 2 ) into the drawing die from the entrance area 1 of the drawing die. The entrance area 1 is coated with lubricating oil (purchased from Houghton International Company, USA). After passing through the die, set the compression coefficient of the drawn aluminum conductor to 0.89, and turn on the drawing machine , under the action of the drum, the aluminum conductor passes through the working area 2, the sizing area 3 and the exit area 4 in turn, and is pulled out horizontally from the exit area 4 to form a compact aluminum conductor with a round cross section and a smooth surface (cut Area 24.0mm 2 ). The material of the drawing die used is cemented carbide, and the cross-section of the sizing area 3 is a full circle with a diameter of 5.53 mm. The drawing die is equipped with a steel jacket.

Embodiment 3

[0039] The circular stranded unpressed aluminum conductor (cross-sectional area 120.4mm 2 ) into the drawing die from the entrance area 1 of the drawing die, and the entrance area 1 is coated with lubricating oil (purchased from Houghton International Corporation of the United States). After passing through the die, set the compression coefficient of the drawn aluminum conductor to 0.90, and start the drawing machine , under the action of the drum, the aluminum conductor passes through the working area 2, the sizing area 3 and the exit area 4 in turn, and is pulled out horizontally from the exit area 4 to form a compact aluminum conductor with a round cross section and a smooth surface (cut Area 114.4mm 2 ). The material of the drawing die used is tungsten steel, the section of the sizing area 3 is a full circle with a diameter of 12.07mm, and the inner surface is treated with a mirror surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com