A modified aluminum borate whisker and its composite floor tile made of waste plastic

A technology of aluminum borate whiskers and waste plastics, applied in the field of building materials, can solve the problems of different physical shapes and chemical structures, affect the performance of composite floor tiles, and uneven dispersion of inorganic fillers, etc., achieve high strength, improve toughness, and combine sex improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

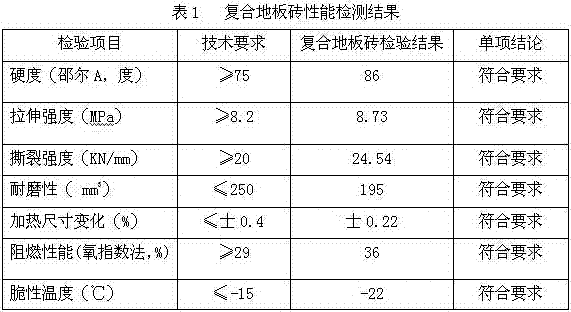

Embodiment 1

[0051] Make modified aluminum borate whiskers according to the following steps:

[0052] a. Stir 0.5Kg of isopropyl distearoyl methacryloyl titanate and 1.5Kg of liquid paraffin at 20°C with a mixer for 4 minutes to obtain a coupling agent dilution;

[0053]b. Add 95Kg of aluminum borate whiskers into a high-speed mixer, heat and stir, add the above coupling agent diluent at 80°C, and mix for 7 minutes to obtain modified aluminum borate whiskers.

[0054] Follow the steps below to make composite floor tiles:

[0055] a. After cleaning 200Kg of waste polyethylene and 200Kg of polypropylene plastic, dry it at 100°C for 1.5h, and then crush it to less than 5mm to obtain product A;

[0056] b. Mix A product and 300Kg modified aluminum borate whiskers evenly with a high-speed mixer to obtain B product;

[0057] c. Put product B on a three-roll mill and masticate it into a sheet at a temperature of 130°C and a sheet thickness of 0.6mm, and then send it to a hot press for molding a...

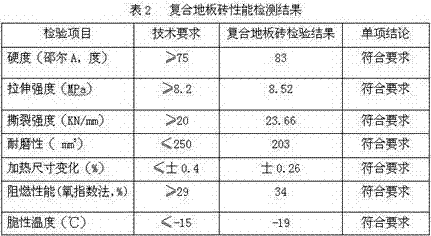

Embodiment 2

[0063] Make modified aluminum borate whiskers according to the following steps:

[0064] a. Stir 0.7Kg of isopropyl distearoyl methacryloyl titanate and 3Kg of liquid paraffin at 20°C for 4 minutes with a mixer to obtain a coupling agent dilution;

[0065] b. Add 97Kg of aluminum borate whiskers into a high-speed mixer, heat and stir, add the above coupling agent diluent at 80°C, and mix for 7 minutes to obtain modified aluminum borate whiskers.

[0066] Follow the steps below to make composite floor tiles:

[0067] a. Wash 300Kg of waste polyethylene and 300Kg of polypropylene plastic, dry at 100°C for 1.5h, and then crush to less than 5mm to obtain product A;

[0068] b. Mix A product and 400Kg modified aluminum borate whiskers evenly with a high-speed mixer to obtain B product;

[0069] c. Put product B on a three-roll mill and masticate it into a sheet at a temperature of 130°C and a sheet thickness of 0.6mm, and then send it to a hot press for molding at a temperature o...

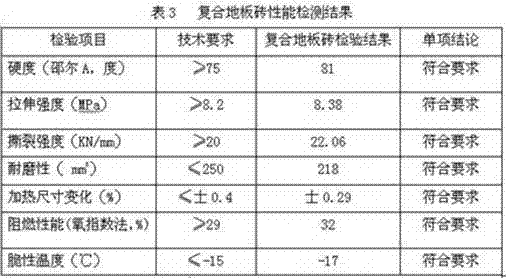

Embodiment 3

[0075] Make modified aluminum borate whiskers according to the following steps:

[0076] a. Stir 2Kg isopropyl triisostearate titanate and 4Kg liquid paraffin at 20°C for 4 minutes with a mixer to obtain a coupling agent dilution;

[0077] b. Add 100Kg of aluminum borate whiskers into a high-speed mixer, heat and stir, add the above coupling agent diluent at 80°C, and mix for 7 minutes to obtain modified aluminum borate whiskers.

[0078] Follow the steps below to make composite floor tiles:

[0079] a. Wash 350Kg of waste polyethylene and 350Kg of polypropylene plastic, dry at 100°C for 1.5h, and then crush to less than 5mm to obtain product A;

[0080] b. After mixing product A and 430Kg modified aluminum borate whiskers with a high-speed mixer, product B was obtained;

[0081] c. Put product B on a three-roller mill and masticate it into a sheet at a temperature of 130°C and a sheet thickness of 0.5mm, and then send it to a hot press for molding at a temperature of 150°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com