Apparatus for high gravity removal of hydrogen sulfide of novel industrial gas, and technology thereof

A technology for industrial gas and hydrogen sulfide, which is used in the preparation/purification of sulfur, chemical instruments and methods, separation methods, etc., can solve problems such as complex processes, and achieve the effects of simplifying the process flow, enhancing mass transfer efficiency, and reducing equipment size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

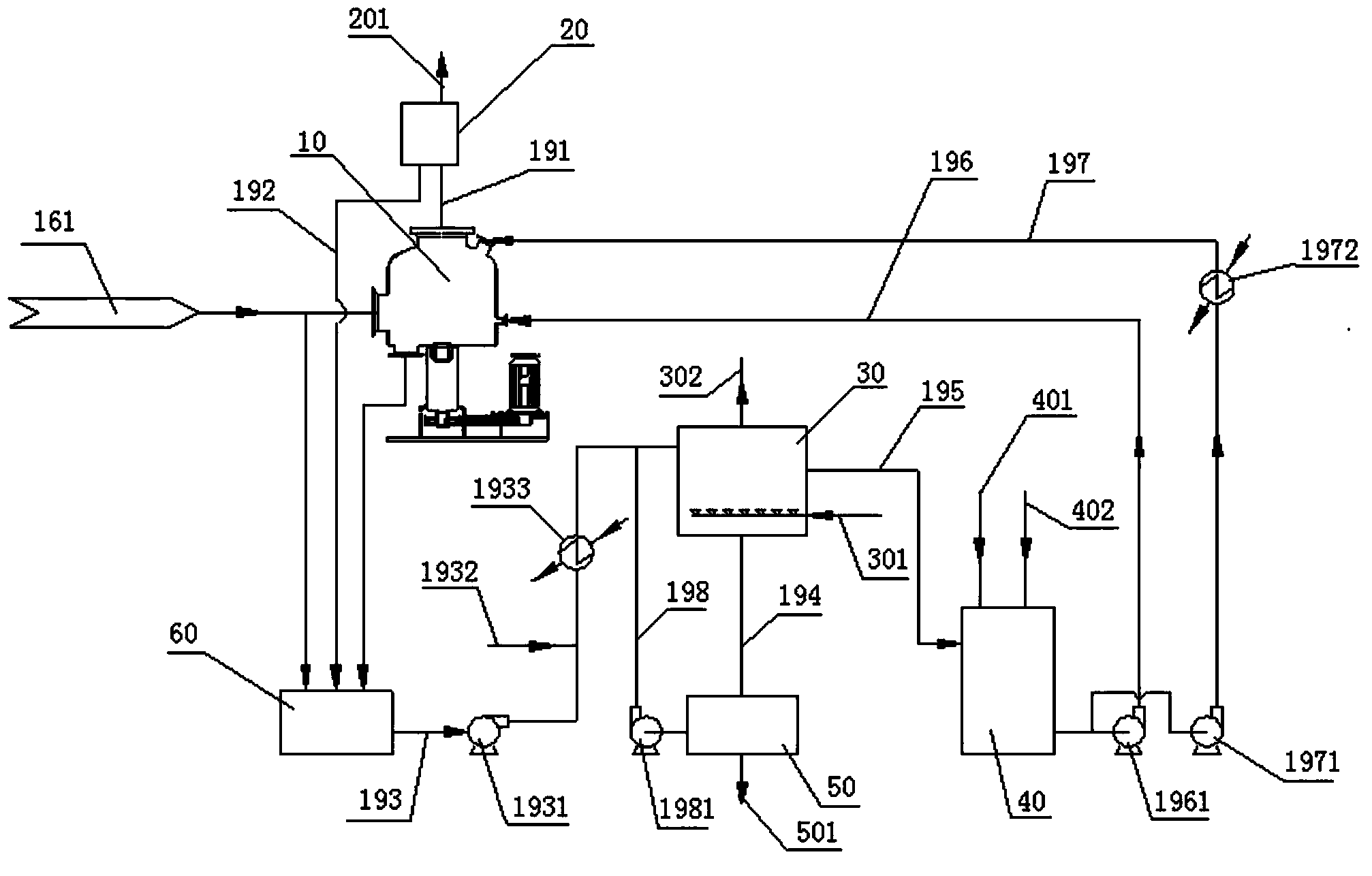

[0044] A new type of device for removing hydrogen sulfide from industrial gases by supergravity, including a supergravity machine 10, a gas-liquid separation device 20, an oxidation tank 30, a lean liquid tank 40, a drum vacuum filter 50 and a rich liquid tank 60;

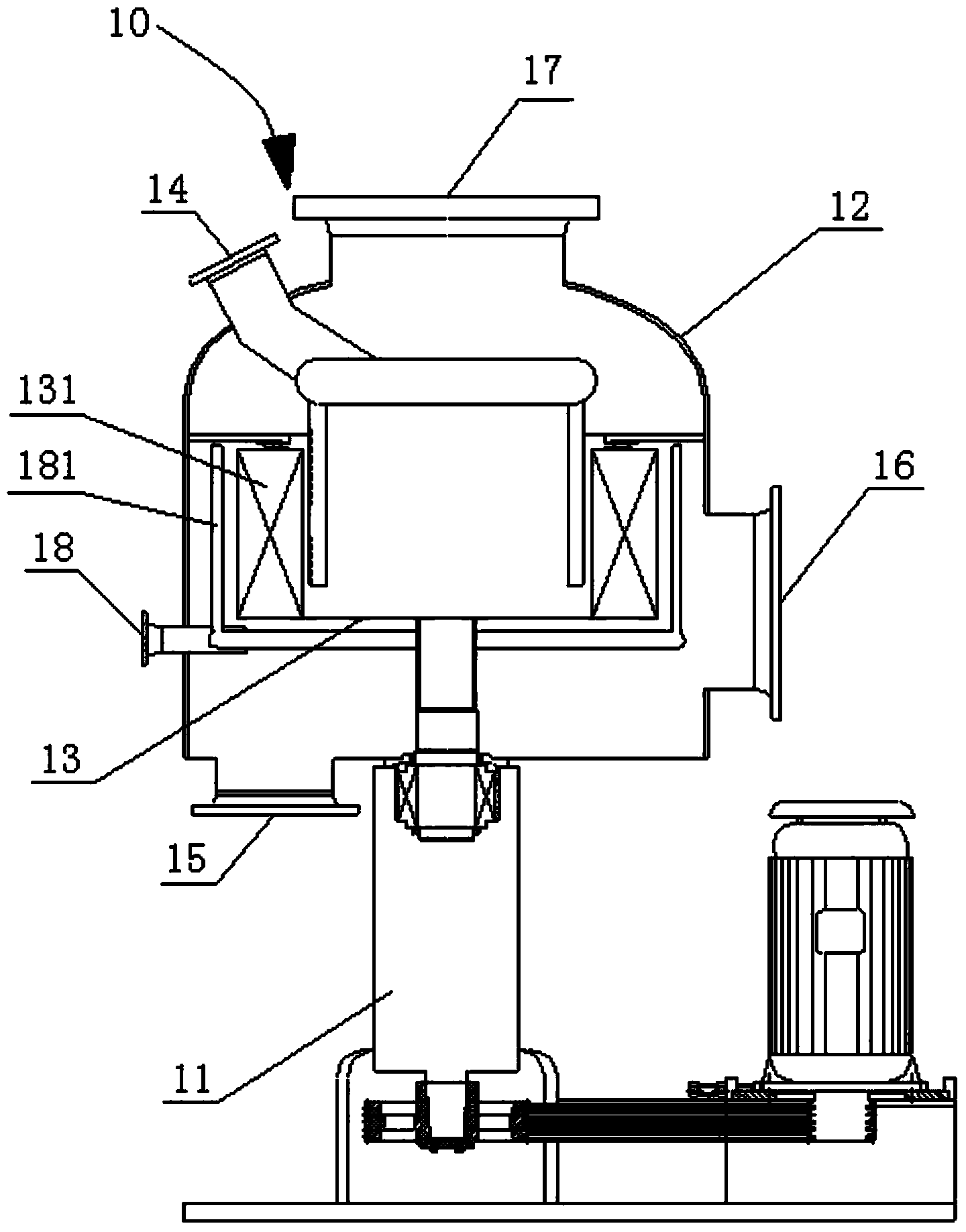

[0045] The supergravity machine 10 comprises a power unit 11, a housing 12, a rotor 13, a liquid inlet 14, a liquid outlet 15, a gas inlet 16, a gas outlet 17 and a flushing liquid inlet 18; the power unit 11 is a motor, and the motor finally The output shaft of the transmission extends into the housing 12 and is fixedly connected with the rotor 13. The upper end of the housing 12 is provided with a liquid inlet 14 and a gas phase outlet 16, and the lower end of the housing 12 is provided with a liquid outlet 15 and a gas inlet 16; the rotor 13 is provided with a packing 131, and the outer layer of the rotor packing 131 is provided with a backwashing device 181, and the backwashing device 181 is connected to the flu...

Embodiment 2

[0068] Use the device and technology of embodiment 1 to carry out oilfield associated gas removal hydrogen sulfide:

[0069] Capacity: 10000Nm 3 / d, pressure 10MPa, hydrogen sulfide content 100ppm, gas temperature 50℃, complex iron as absorbent, absorption liquid consumption 100m 3 / h. After being treated by this process, the associated gas H is exported 2 The S content is less than 3ppm.

Embodiment 3

[0071] Use the device and technique of embodiment 1 to carry out the removal of hydrogen sulfide from natural gas:

[0072] Capacity: 50000Nm 3 / d, pressure 0.9MPa, hydrogen sulfide content 5000ppm, gas temperature 5℃, complex iron as absorbent, absorption liquid consumption 100m 3 / h. After being treated by this process, the exported natural gas H 2 The S content is less than 10 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com