Method for performing residual oil hydrogenation reaction in high gravity reactor

A high-gravity reactor and residual oil hydrogenation technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes of energy application, hydrocarbon oil treatment, etc., can solve problems such as difficult to meet requirements, and reduce reaction pressure , Efficient mass transfer efficiency, high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

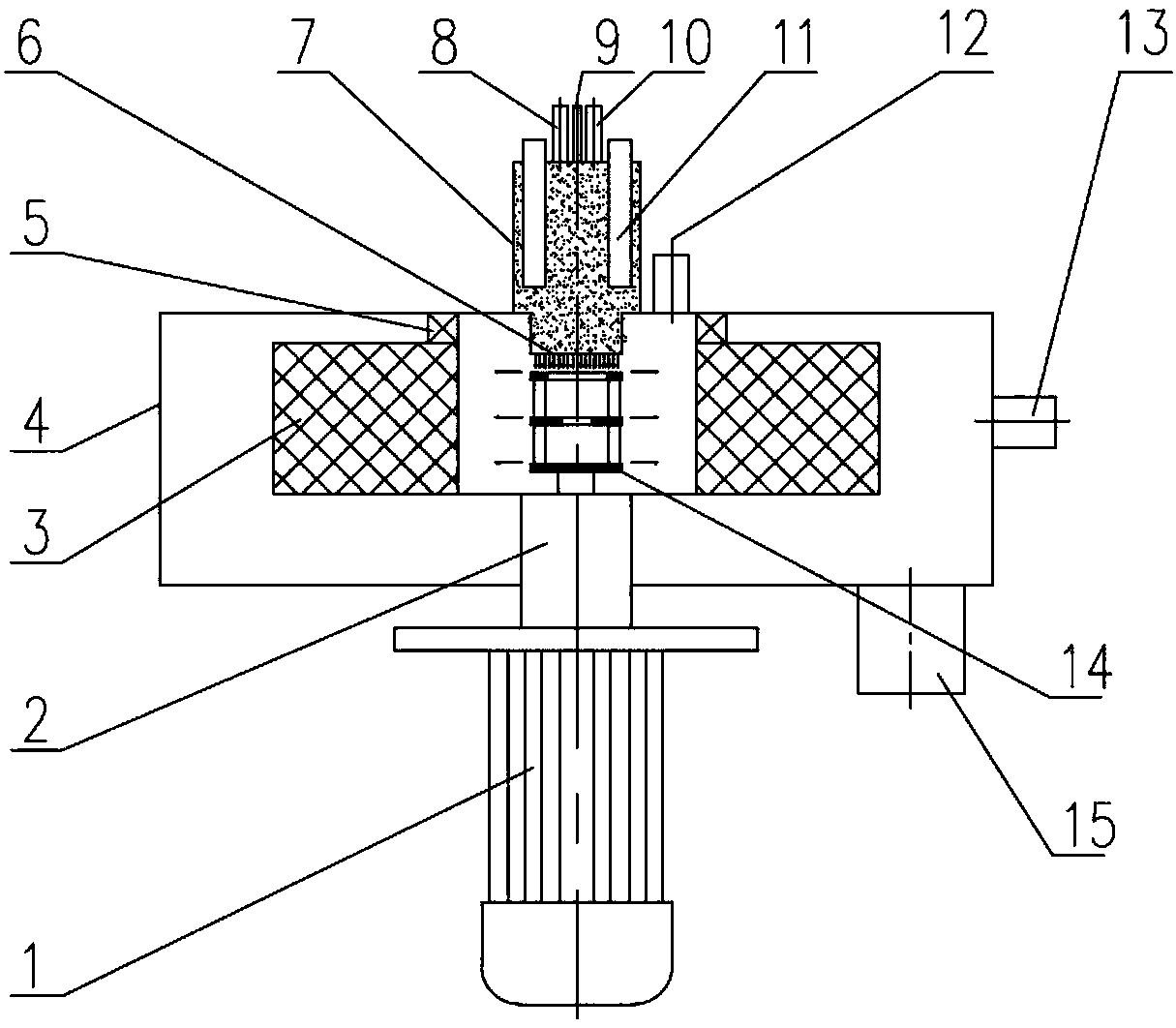

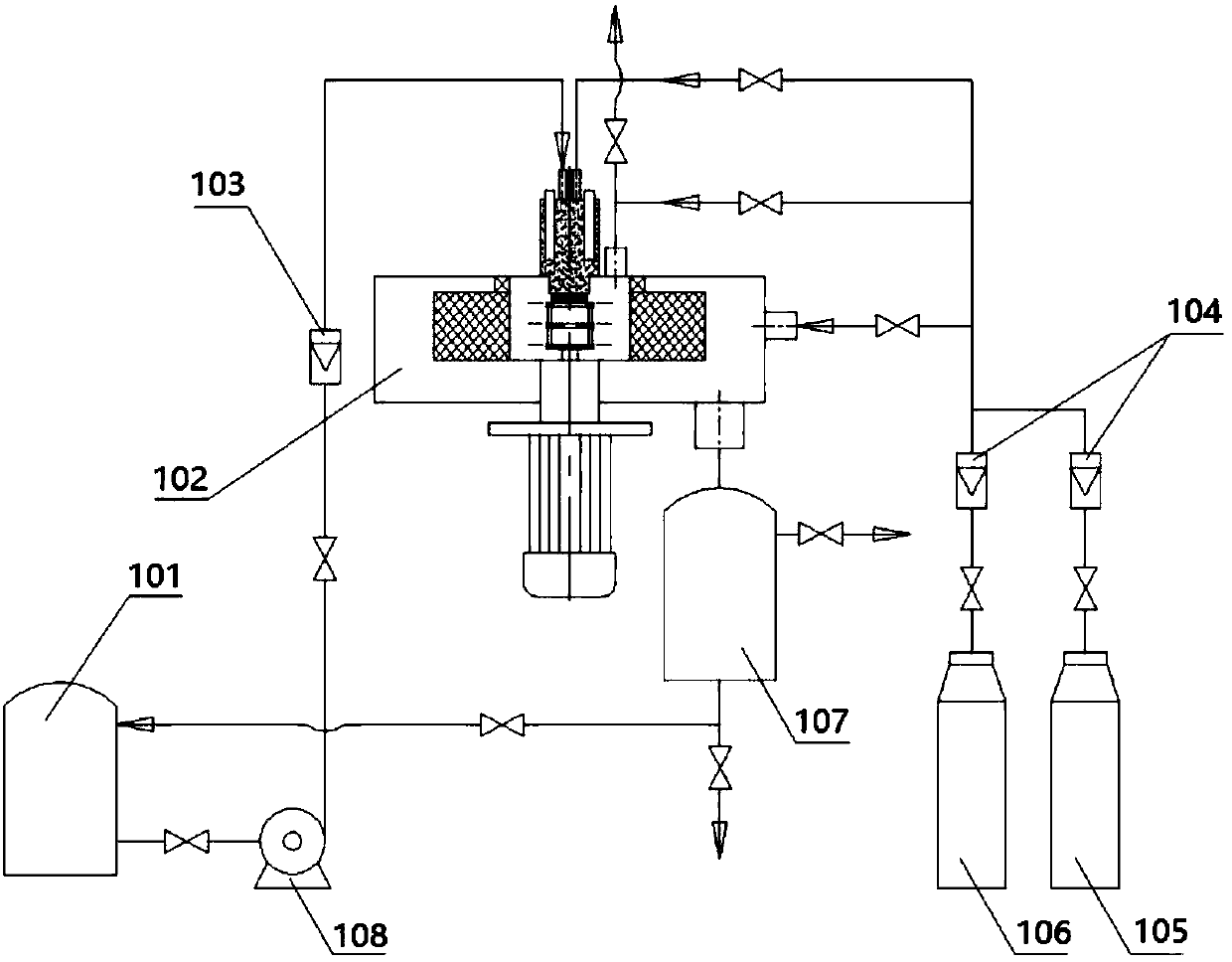

[0057] Such as figure 2 Shown, a method for hydrogenation of residual oil in a high gravity reactor to remove sulfur and nitrogen in the residual oil and vanadium and nickel in metals;

[0058] The temperature of the residual oil hydrogenation reaction in the high gravity reactor is 330-460°C, the pressure is 4-9MPa, and the gas flow rate is controlled to be 1 m 3 / h, the liquid flow rate is 10L / h, the catalyst is packed in the rotor area in a disorderly bulk manner, the mass fraction of sulfur in the imported residual oil is 0.6%, the mass fraction of nitrogen is 0.8%, and the vanadium content is 0.98μg / g , The nickel content is 60μg / g, and the speed is 1600rpm;

[0059] After the reaction, the final liquid outlet desulfurization rate reached 85%, the denitrification rate reached 25%, the vanadium content was 0.55 μg / g, and the nickel content was 45 μg / g. Using a conventional supergravity reactor (such as the one disclosed in Chinese Patent Application CN103102942A), the liquid ...

Embodiment 2

[0061] Such as figure 2 As shown, a method for hydrogenation of residual oil in a high-gravity reactor to remove sulfur, nitrogen and vanadium and nickel from metals in the residual oil; the operating steps are the same as those in Example 1, except that:

[0062] Under the operating conditions of the speed of 2400rpm, the temperature of 550°C and the pressure of 10MPa, the final liquid outlet desulfurization rate after the reaction reached 87%, the denitrification rate reached 28%, the vanadium content was 0.50μg / g, and the nickel content was 35μg / g.

[0063] Using a conventional supergravity reactor (such as the one disclosed in Chinese Patent Application CN104419454A), the liquid outlet desulfurization rate is ≤80%, the denitrification rate is ≤21%, the vanadium content is 0.73μg / g, and the nickel content is 55μg / g . The invention is superior to the existing hydrogenation process of supergravity reactor.

Embodiment 3

[0065] Such as figure 2 As shown, a method for hydrogenation of residual oil in a high-gravity reactor to remove sulfur, nitrogen and vanadium and nickel from metals in the residual oil; the operating steps are the same as those in Example 1, except that:

[0066] The rotor area of the rotating bed is divided into 8 layers of concentric rings. The first layer is a stainless steel wire mesh packing ring. The packing ring and the catalyst ring are alternately placed. Along the rotor radius, there are desulfurization, denitrification, demetalization of vanadium, and demetalization of nickel. catalyst.

[0067] After the reaction, the final liquid outlet desulfurization rate reached 90%, the denitrification rate reached 28%, the vanadium content was 0.45 μg / g, and the nickel content was 33 μg / g.

[0068] Using a conventional supergravity reactor (such as the one disclosed in Chinese patent application CN103102942A), the liquid outlet desulfurization rate is ≤80%, the denitrification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com