Method for selective hydrogenation of pyrolysis gasoline

A pyrolysis gasoline and selective hydrogenation technology, which is applied in the petroleum industry, refining hydrocarbon oil, etc., can solve the problems of loss of active metal components, high friction of catalyst particles, and difficult processing of metal mesh, so as to improve catalytic performance and equipment The effect of small size and easy filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

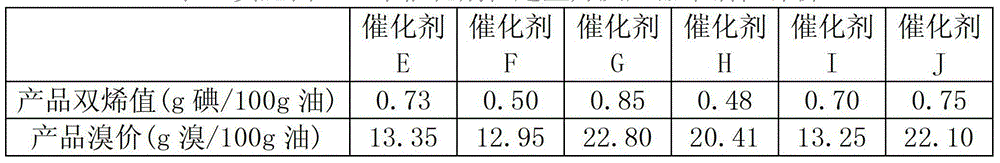

[0064] The metal catalyst A was ground into a fine powder, and sieved to obtain a catalyst powder with a particle size of 100 mesh. Select a polypropylene plastic rope with a diameter of 1.5 mm and place it in the powder of the metal catalyst A, mold it with a flat vulcanizer at a temperature of 200 ° C and a pressure of 7 MPa for 10 min, take it out and cool it, and obtain a metal-polymer catalyst, called is the metal-polymer catalyst E.

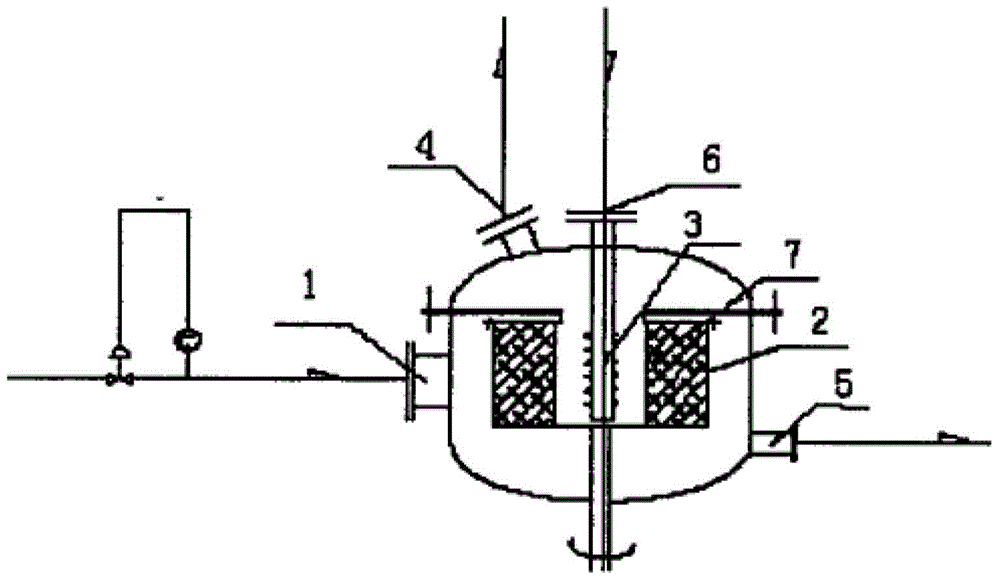

[0065] The metal-polymer catalyst E is densely wound to form a ring-shaped integral catalyst inner part, and the metal-polymer catalyst is fixed on the rotor of the high-gravity rotating bed reactor. The integral catalyst inner part and the rotor are connected by bolts, and the metal-polymer Catalyst E can move together with the high-speed rotating rotor of the hypergravity reactor.

Embodiment 2

[0067]The metal catalyst B was ground into a fine powder, and sieved to obtain a catalyst powder with a particle size of 100 mesh. Select a polypropylene plastic rope with a diameter of 1.5 mm and place it in the powder of the metal catalyst B, mold it with a flat vulcanizer at a temperature of 200 ° C and a pressure of 7 MPa for 10 min, take it out and cool it, and obtain a metal-polymer catalyst, called is the metal-polymer catalyst F.

[0068] The metal-polymer catalyst F is densely wound to make a ring-shaped monolithic catalyst inner part, and the metal-polymer catalyst is fixed on the rotor of the high-gravity rotating bed reactor. The monolithic catalyst inner part and the rotor are connected by bolts, and the metal-polymer Catalyst F can move together with the high-speed rotating rotor of the hypergravity reactor.

Embodiment 3

[0070] The metal catalyst C was ground into a fine powder and sieved to obtain a catalyst powder with a particle size of 80 mesh. Select 10-mesh nylon-6 wire mesh and place it in the powder of metal catalyst C, mold it with a flat vulcanizer at a temperature of 250°C and a pressure of 7 MPa for 10 minutes, take it out and cool it, and then obtain a metal-polymer catalyst, which is called metal catalyst C. - polymer catalyst G.

[0071] The metal-polymer catalyst G is compacted to form a net-like monolithic catalyst internal, and the metal-polymer catalyst is fixed on the rotor of the high-gravity rotating bed reactor. The monolithic catalyst internal and the rotor are connected by bolts, and the metal-polymer Catalyst G can move together with the high-speed rotating rotor of the hypergravity reactor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com