Preparation method and application of noble metal monolithic catalyst for purifying formaldehyde

A monolithic catalyst, formaldehyde purification technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high purification temperature, low formaldehyde removal efficiency, Problems such as low purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

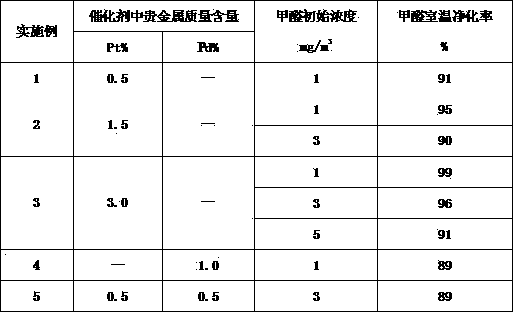

Embodiment 1

[0017] Take 7.3 g sheet-shaped activated carbon fiber felt (22×16×0.4cm in size) and heat and boil in 10wt% nitric acid solution for 20 minutes, take it out, rinse it with distilled water, and dry it at 120°C to constant weight. Take 95mL of 1 g / L chloroplatinic acid solution and adjust the pH value to 8-9 with 2 mol / L sodium hydroxide solution to prepare a noble metal precursor solution, and then drop it evenly on the surface of the pretreated activated carbon fiber felt until The activated carbon fiber mat reaches adsorption saturation, and then the saturated activated carbon fiber mat is aged at room temperature for 4 h, and then aged at 60 °C for 4 h. The prepared 0.1 mol / L sodium borohydride aqueous solution was evenly dropped on the surface of the activated carbon fiber felt on which the noble metal precursor had been deposited, and dried at 120 °C for 5 h after the reaction was complete. In the monolithic catalyst obtained in this example, the mass content of noble meta...

Embodiment 2

[0019] Take 2.0 g sheet-shaped activated carbon fiber felt (12×9.5×0.4cm in size) and heat and boil in 10wt% nitric acid solution for 20 minutes, take it out, rinse it with distilled water, and dry it at 120°C to constant weight. Take 26mL of 3 g / L chloroplatinic acid solution and adjust the pH value to 8-9 with 2 mol / L sodium hydroxide solution to prepare a noble metal precursor solution, and then drop it evenly on the surface of the pretreated activated carbon fiber felt until The activated carbon fiber mat reaches adsorption saturation, and then the saturated activated carbon fiber mat is aged at room temperature for 4 h, and then aged at 60 °C for 4 h. The prepared 0.1 mol / L sodium borohydride aqueous solution was evenly dropped on the surface of the activated carbon fiber felt on which the noble metal precursor had been deposited, and dried at 120 °C for 5 h after the reaction was complete. In the monolithic catalyst obtained in this example, the mass content of noble met...

Embodiment 3

[0021] Take 9.2 g sheet-shaped activated carbon fiber felt (28×15×0.4cm in size) and heat and boil in 10wt% nitric acid solution for 20 minutes, take it out, rinse it with distilled water, and dry it at 120°C to constant weight. Take 120 mL of 6.1 g / L chloroplatinic acid solution and adjust the pH value to 8-9 with 2 mol / L sodium hydroxide solution to prepare a noble metal precursor solution, and then drop it evenly on the surface of the pretreated activated carbon fiber felt until The activated carbon fiber mat reaches adsorption saturation, and then the saturated activated carbon fiber mat is aged at room temperature for 4 h, and then aged at 60 °C for 4 h. The prepared 0.1 mol / L sodium borohydride aqueous solution was evenly dropped on the surface of the activated carbon fiber felt on which the noble metal precursor had been deposited, and dried at 120 °C for 5 h after the reaction was complete. In the monolithic catalyst obtained in this example, the mass content of noble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com