Quantum dot fluorescent aspirin imprinted sensor and its preparation method and use

A technology of aspirin and quantum dots, which is applied in the field of material preparation and drug content detection, can solve the problems of time-consuming, large solvent consumption, tedious sample pretreatment and selectivity, and achieve good optical stability, sensitivity and selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

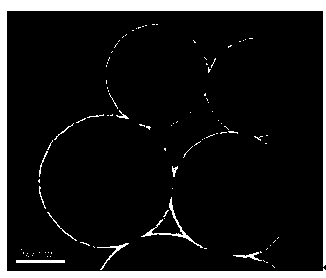

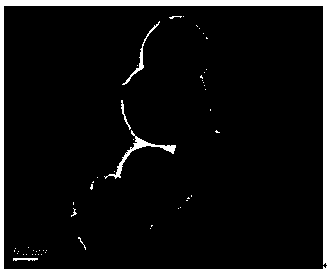

Image

Examples

Embodiment 1

[0031] (1) 30.3 mg sodium borohydride (NaBH 4 ) and 51.04 mg of tellurium powder were added to the centrifuge tube, and then 3.0 mL of twice-distilled water was added to dissolve the solid completely; the centrifuge tube was placed in an ultrasonic machine for ultrasonic reaction, and the mouth of the tube was kept to vent gas, and the final white liquid was the desired The precursor NaHTe solution.

[0032] (2) Inject the newly obtained precursor NaHTe into the CdCl with thioglycolic acid (TGA) at a pH of 10.5 for nitrogen and deoxygenation 2 In aqueous solution, to which 228.34 mg of CdCl was added 2 2.5H 2 O and 138.5 μL of TGA. Mixed solution under nitrogen protection 100 o C under reflux reaction for 60 hours to obtain red fluorescent quantum dots.

[0033] (3) Mix 3 mL of quantum dot stock solution and 10 mL of twice distilled water into the flask, add 11.7 μL of (3-aminopropyl)triethoxysilane and 4.5 mg of aspirin at the same time, and stir for 20 min. Then 44.8 μ...

Embodiment 2

[0036] (1) 60.6 mg sodium borohydride (NaBH 4 ) and 51.04 mg of tellurium powder were added to the centrifuge tube, and then 3.0 mL of twice-distilled water was added to dissolve the solid completely; the centrifuge tube was placed in an ultrasonic machine for ultrasonic reaction, and the mouth of the tube was kept to vent gas, and the final white liquid was the desired The precursor NaHTe solution.

[0037] (2) Inject the newly obtained precursor NaHTe into the CdCl with thioglycolic acid (TGA) at a pH of 11.5 for nitrogen and deoxygenation 2 in aqueous solution to which 152.23 mg of CdCl was added 2 2.5H 2 O and 115.44 μL of TGA. The mixed solution was protected under nitrogen at 110 o C under reflux reaction for 60 hours to obtain red fluorescent quantum dots.

[0038] (3) Mix 0.1 mL of quantum dot stock solution and 10 mL of twice distilled water into the flask, add 70.2 μL (3-aminopropyl)triethoxysilane and 4.5 mg of aspirin at the same time, and stir for 30 min. Th...

Embodiment 3

[0041] (1) Add 45.4 mg sodium borohydride (NaBH 4 ) and 51.04 mg of tellurium powder were added to the centrifuge tube, and then 3.0 mL of twice-distilled water was added to dissolve the solid completely; the centrifuge tube was placed in an ultrasonic machine for ultrasonic reaction, and the mouth of the tube was kept to vent gas, and the final white liquid was the desired The precursor NaHTe solution.

[0042] (2) Inject the newly obtained precursor NaHTe into CdCl with thioglycolic acid (TGA) at a pH of 11.2 for nitrogen and deoxygenation 2 in aqueous solution to which 182.672 mg of CdCl was added 2 2.5H 2 O and 133 μL of TGA. Mixed solution under nitrogen protection 105 o C under reflux reaction for 60 hours to obtain red fluorescent quantum dots.

[0043] (3) Mix 2 mL of quantum dot stock solution and 10 mL of twice distilled water into the flask, add 23.4 μL of (3-aminopropyl)triethoxysilane and 4.5 mg of aspirin at the same time, and stir for 25 min. Then 112 μL t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com