Preparation method of noble metal-loaded activated carbon fiber monoatomic catalyst for catalytic degradation of VOCs at room temperature

An activated carbon fiber, catalytic degradation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high energy consumption, easy generation of by-products, catalytic degradation Advanced problems, to achieve the effect of large specific surface area, economical cost saving, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

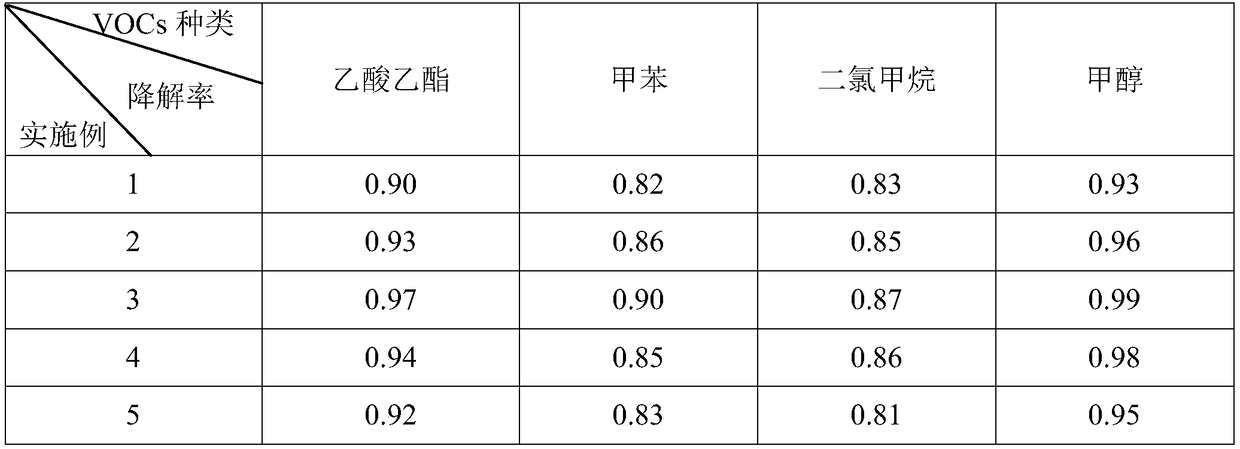

Examples

preparation example Construction

[0023] A kind of preparation method of the activated carbon fiber single-atom catalyst of the load noble metal that is used for catalytic degradation of VOCs at room temperature of the present invention, comprises the following steps:

[0024] (a) Pretreatment of the carrier:

[0025] (1) Immerse the activated carbon fiber in a sulfuric acid solution with a concentration of 5% to 30% by mass, and sonicate for 10-50 minutes.

[0026] (2) Place the sulfuric acid solution in a water bath and react at a constant temperature of 30-90°C for 2-9 hours, then take out the activated carbon fiber from the solution and wash it with distilled water for several times until the pH value of the modified activated carbon fiber is neutral, and then carry out natural Dry in the air to obtain modified activated carbon fibers.

[0027] Preferably, the mass percent concentration of the sulfuric acid solution is 10%-25%. The moderate concentration can dissolve most of the soluble impurities on the...

Embodiment 1

[0040] (a) Pretreatment of the carrier:

[0041] 1) Immerse the activated carbon fiber in a sulfuric acid solution with a concentration of 5% by mass, and sonicate for 10 minutes.

[0042] 2) Place the sulfuric acid solution in a water bath and react at a constant temperature of 30°C for 2 hours, then take out the activated carbon fiber from the solution and wash it with distilled water for several times until the pH value of the modified activated carbon fiber is neutral, then dry it naturally to obtain the modified Activated carbon fiber.

[0043] (b) Loading of Au:

[0044] (1) Completely impregnate the modified activated carbon fibers in 0.1mol / L HAuCl 4 In the solution, ultrasonic treatment was carried out for 0.5h, and then the noble metal solution impregnated with modified activated carbon fibers was allowed to stand at 10°C for 18h, and the HAuCl 4 The mass ratio of the Au element in the solution to the modified activated carbon fiber is 0.02%.

[0045] 2) Add 10 mL ...

Embodiment 2

[0050] (a) Pretreatment of the carrier:

[0051] 1) Immerse the activated carbon fiber in a sulfuric acid solution with a concentration of 10% by mass, and sonicate for 20 minutes.

[0052] 2) Place the ultrasonic solution in a water bath and heat it at a constant temperature of 40°C for 4 hours, then take out the activated carbon fiber from the solution and wash it with distilled water for several times until the pH value of the modified activated carbon fiber is neutral, and then dry it naturally. Modified activated carbon fibers are obtained.

[0053] (b) Loading of Pd:

[0054] (1) Completely impregnate the modified activated carbon fibers in PdSO with a concentration of 0.2mol / L 4 solution, ultrasonic treatment was carried out for 1 h, and then the noble metal solution impregnated with modified activated carbon fibers was left to stand for 20 h at 15 ° C, and the PdSO 4 The mass ratio of the Pd element in the solution to the modified activated carbon fiber is 0.08%.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com