Patents

Literature

33 results about "Pd element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed C3/C4 alkane dehydrogenation catalyst and preparation method thereof

The invention relates to a mixed low carbon alkane dehydrogenation catalyst and a preparation method thereof. A problem of low activity of dehydrogenation catalysts prepared through present technologies is mainly solved. The mixed low carbon alkane dehydrogenation catalyst comprises 0.1-10% of Pt and Pd elements or oxides thereof, 0.25-10wt% of Sn, Fe, Ni elements or oxides thereof, 0.1-10wt% of Na, Li and K elements or oxides thereof, 0-10wt% of Nb, Mo, Ta and W elements or oxides thereof, and 70-99wt% of ZSM-5 with different Si / Al ratios. The mixed low carbon alkane dehydrogenation catalyst well solves the problem, and can be used in the industrial production for preparing low carbon olefins through the mixed low carbon alkane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

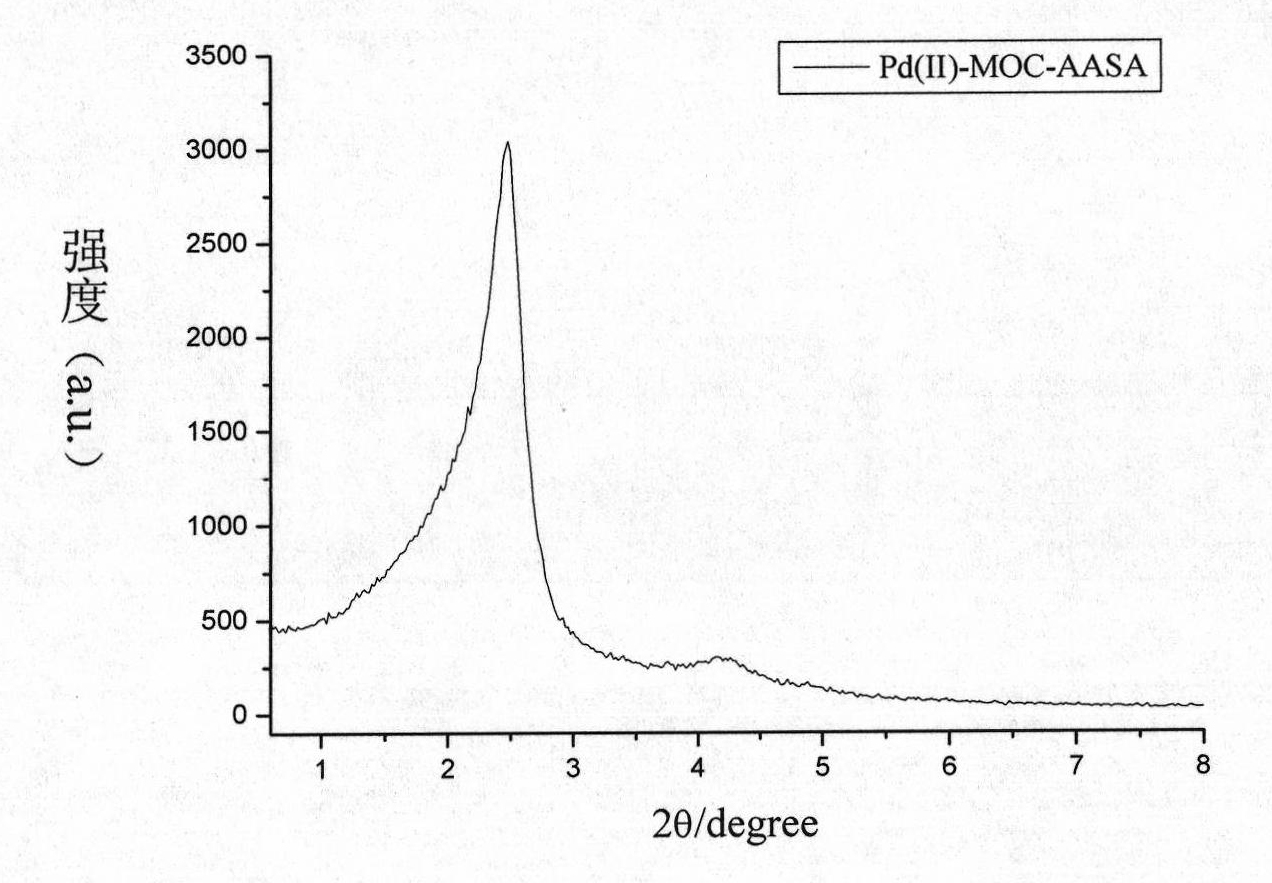

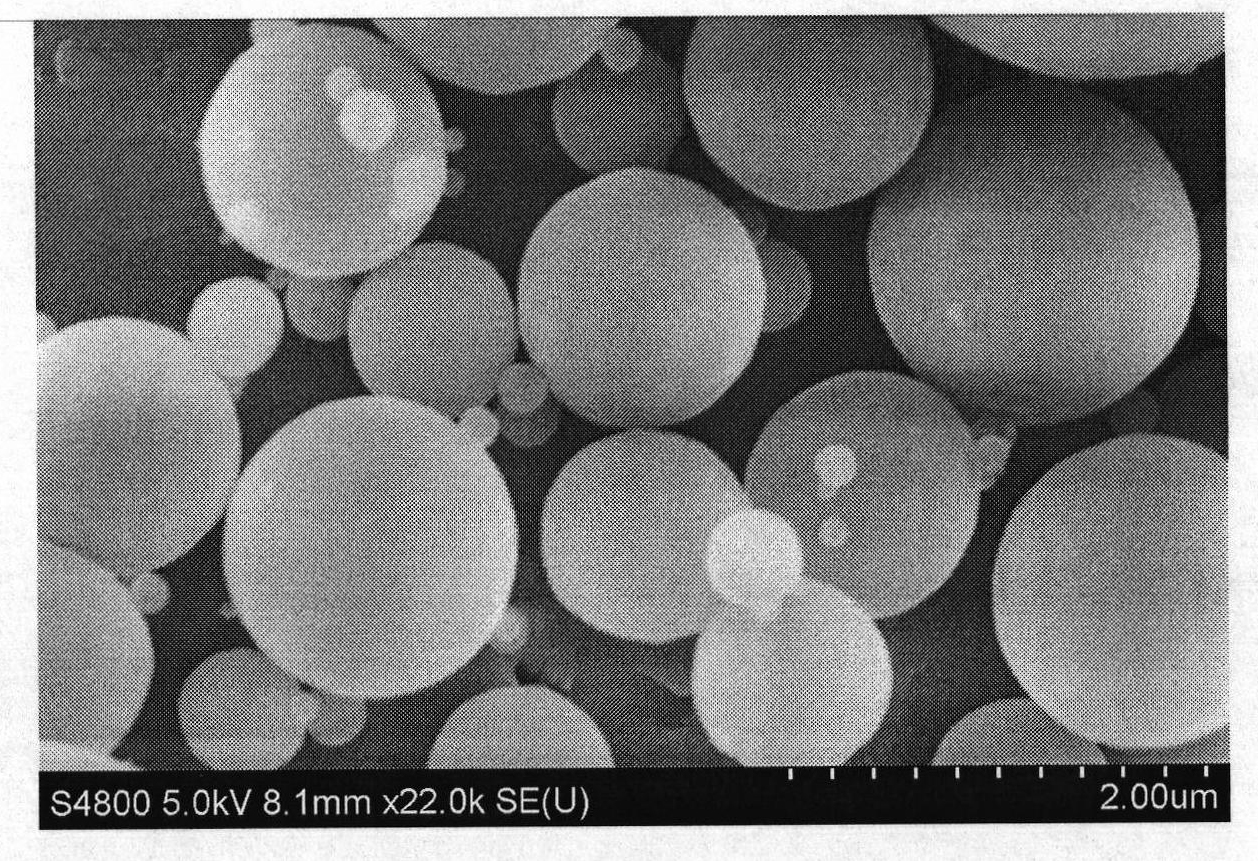

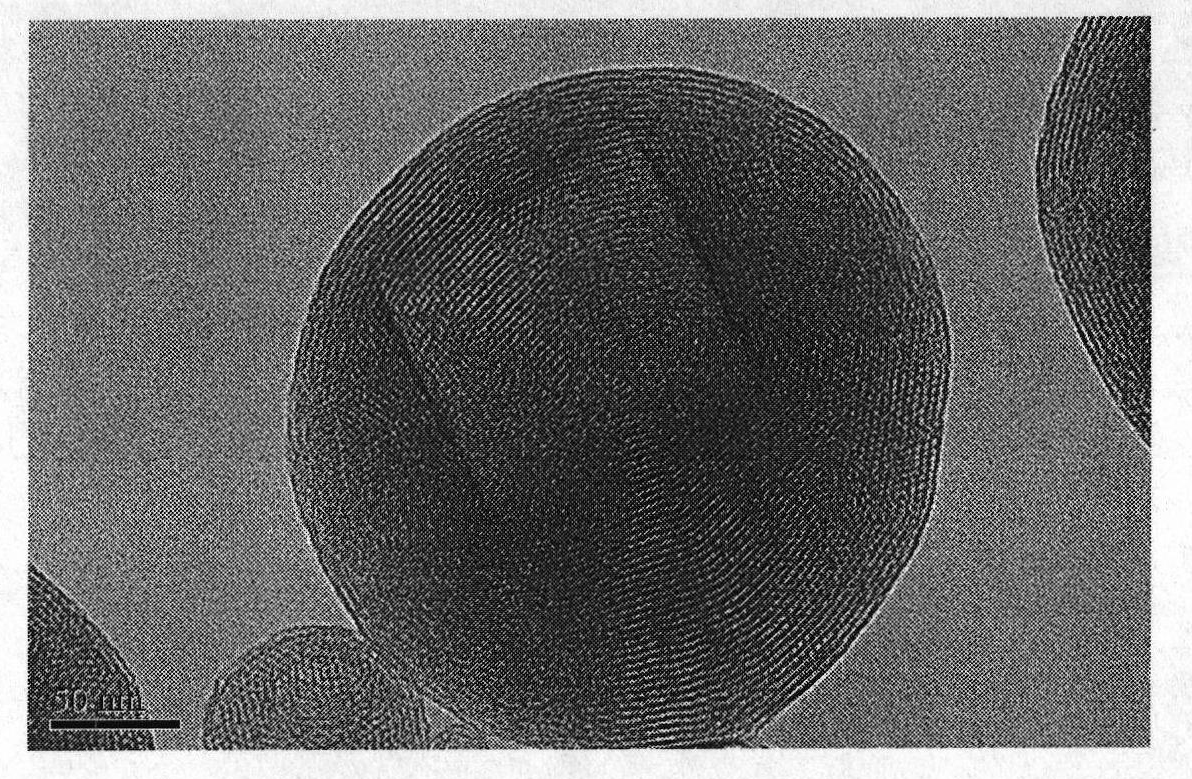

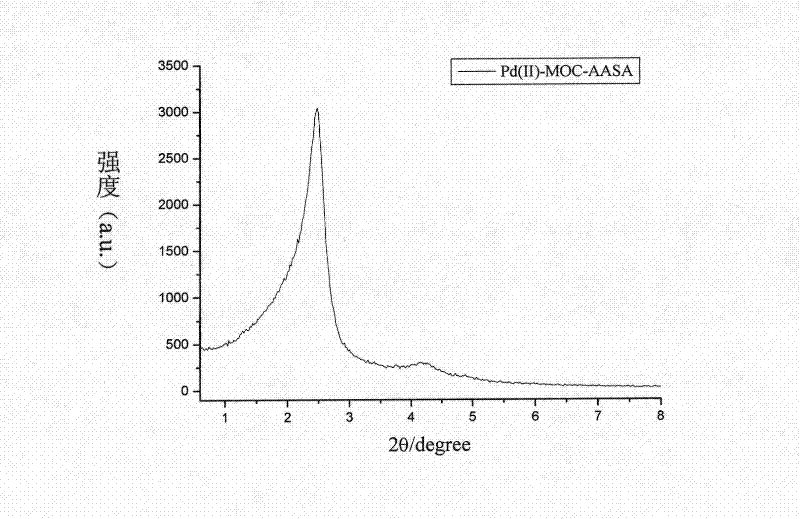

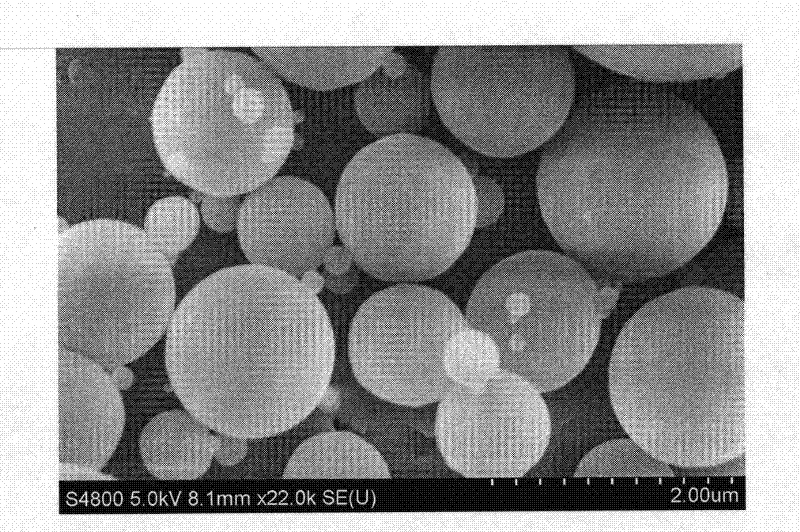

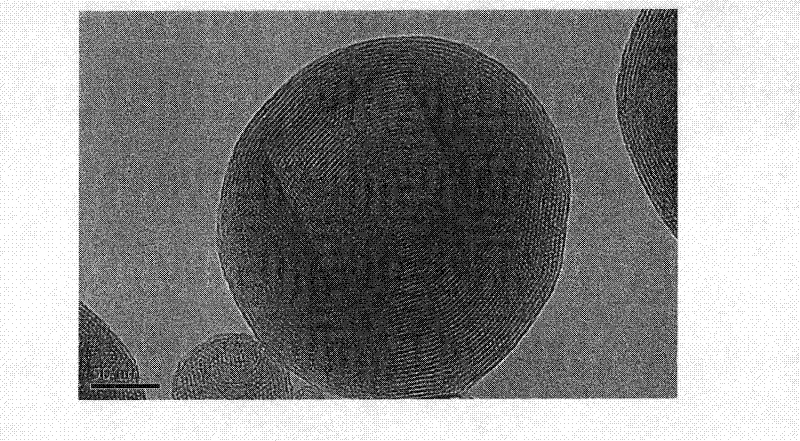

Nano-spherical mesoporous organic metal catalyst, preparation method and application thereof

InactiveCN101773854AEasy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganometallic catalysisSilanes

The invention discloses a nano-spherical mesoporous organic metal catalyst. In the nano-spherical mesoporous organic metal catalyst, the grain diameter is between 100 and 600nm, the pore diameter is between 1.5 and 8.0nm, the pore volume is between 0.2 and 1.0cm<3> / g, the specific surface area is between 800 and 1,200m<2> / g, and the Pd element content is between 0.05 and 0.35mmol / g. The preparation method comprises the following steps: mixing organic metal silane, solution of inorganic silane, a template, water and ethanol; performing a hydrolytic polycondensation reaction by using a spray drying method; and extracting the template from an obtained solid by using alcohols to prepare the nano-spherical mesoporous organic metal catalyst. By using the method, an organic metallic catalyst with ordered mesopore arrangement can be quickly prepared, the active ingredients of the organic metallic catalyst are highly dispersed in pore passages, and the organic metallic catalyst serves as a catalyst for Barbier reaction or Sonogashira reaction in a water medium, and the organic metallic catalyst can have the catalytic performance similar to that of a homogenous organic metal catalyst.

Owner:SHANGHAI NORMAL UNIVERSITY

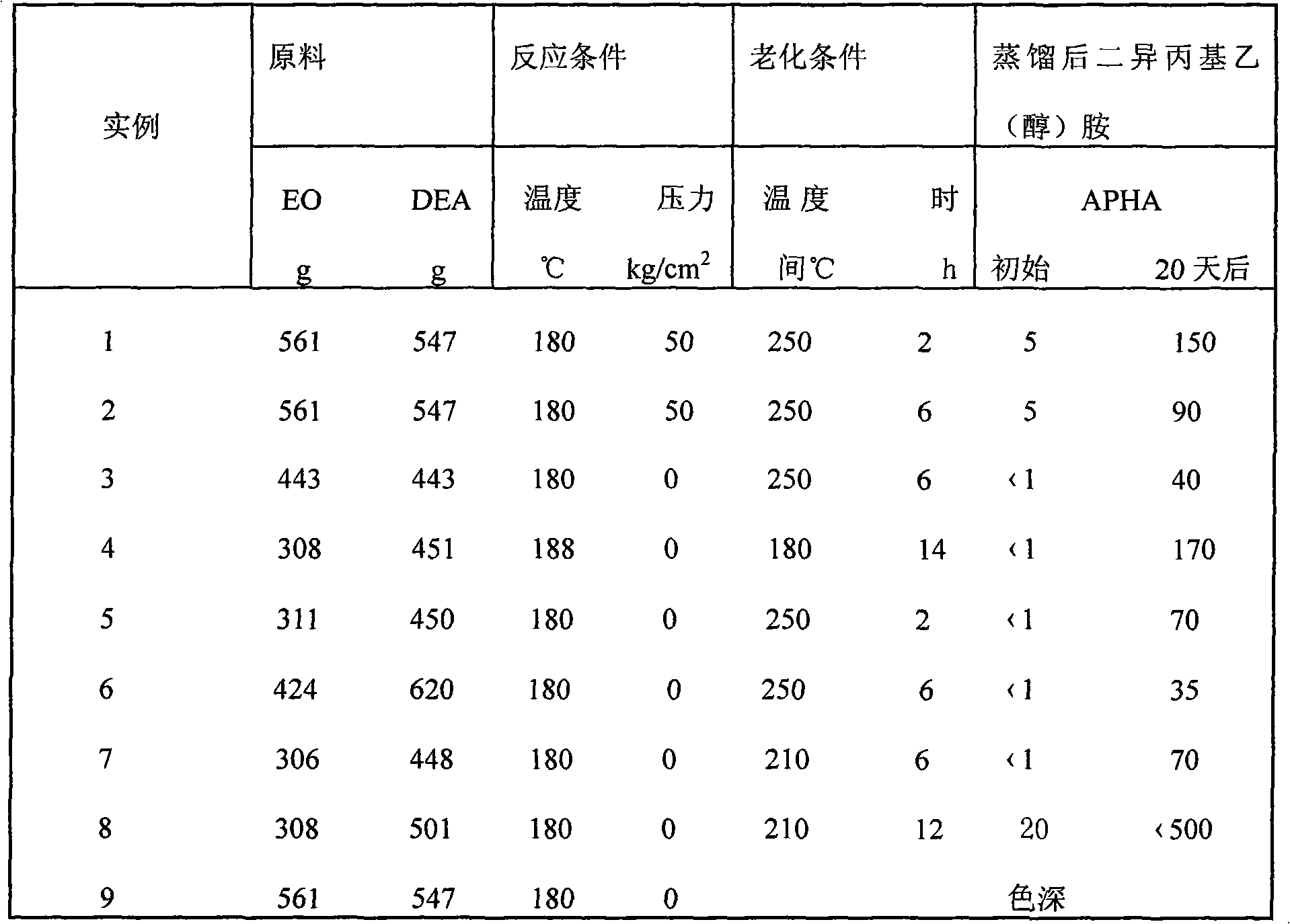

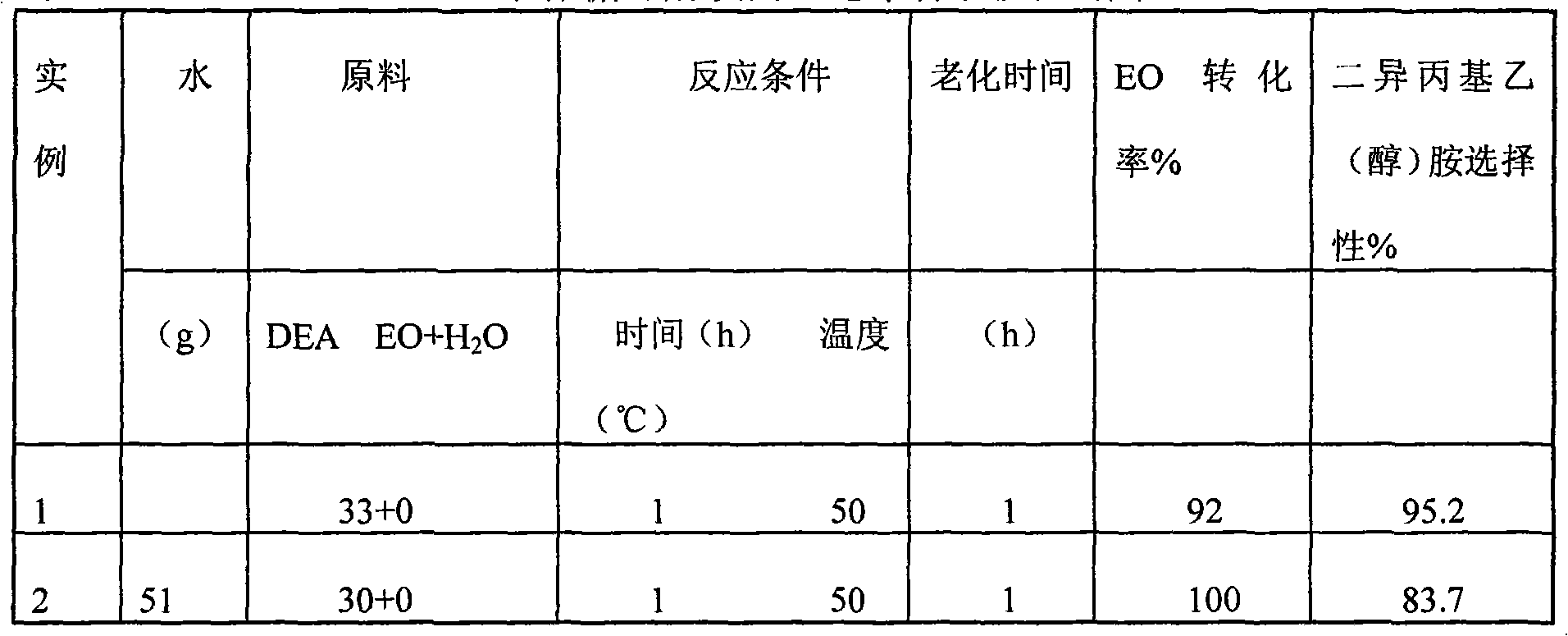

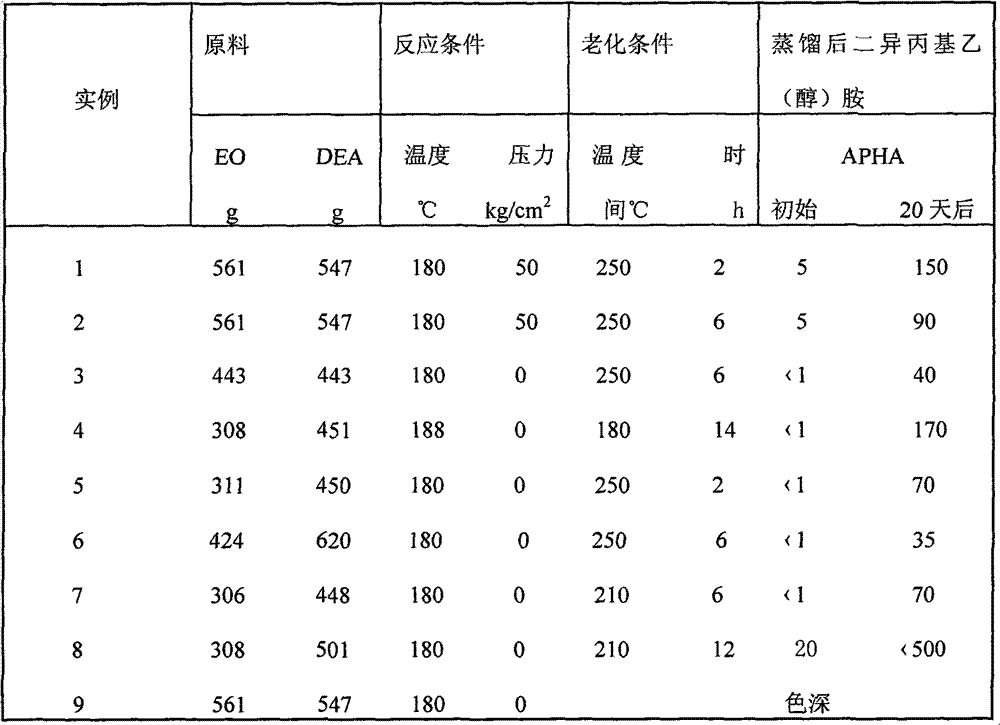

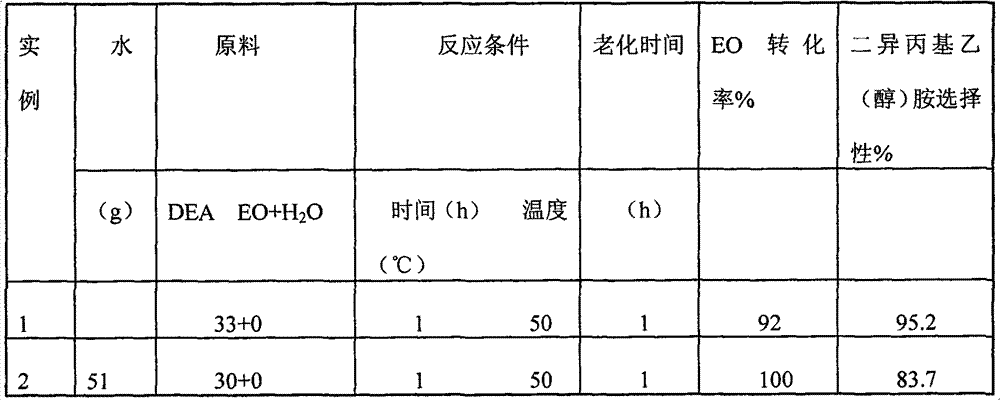

Method for synthetizing N,N-diisopropylethylamine

InactiveCN101585776ASimple processHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyMoisture

The invention relates to a method for synthetizing N,N-diisopropylethylamine; the method comprises the steps as follows: taking diisopropylamine, epoxy ethane as the raw material, taking zinc chloride, tetramethyl ammonium hydroxide as the catalyst, taking the water as the circulating medium, reacting and aging; the reaction is carried out under gas and liquid phases utilizing single kettle production; the specific operating conditions being normal pressure, the temperature being 50 to 180 degrees centigrade, the air speed of ethylene oxide gas being 50 to 100 kg / h, the mol ratio between diisopropylamine and epoxy ethane being 1-1.5, the dosage of the catalyst being 0.5-1 weight of diisopropylamine; thermal reacting for two hours, then discharging and filtering to remove the solid catalyst, evaporating diisopropylamine and moisture under normal pressure, adding with activated carbon dipping with Ru, Pt or Pd elements, decompressing, rectifying, collecting the products. The invention has the advantages of taking the water solution of the diisopropylamine as the main reaction line, adding with little catalyst into the water solution of the diisopropylamine, and reacting through the epoxy ethane under normal pressure, having excellent reaction effect.

Owner:HANGZHOU XINDE ENVIRONMENTAL PROTECTION TECH

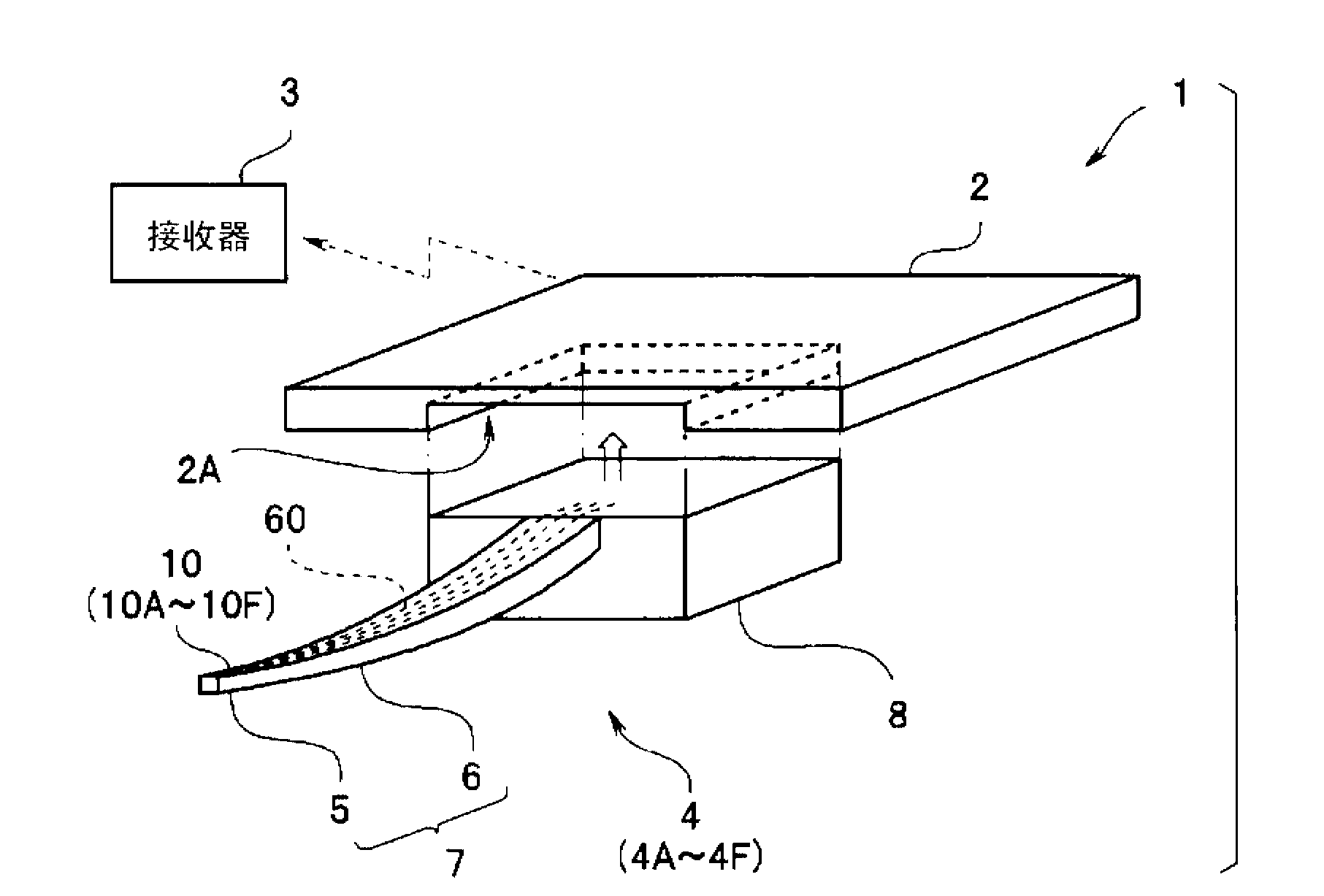

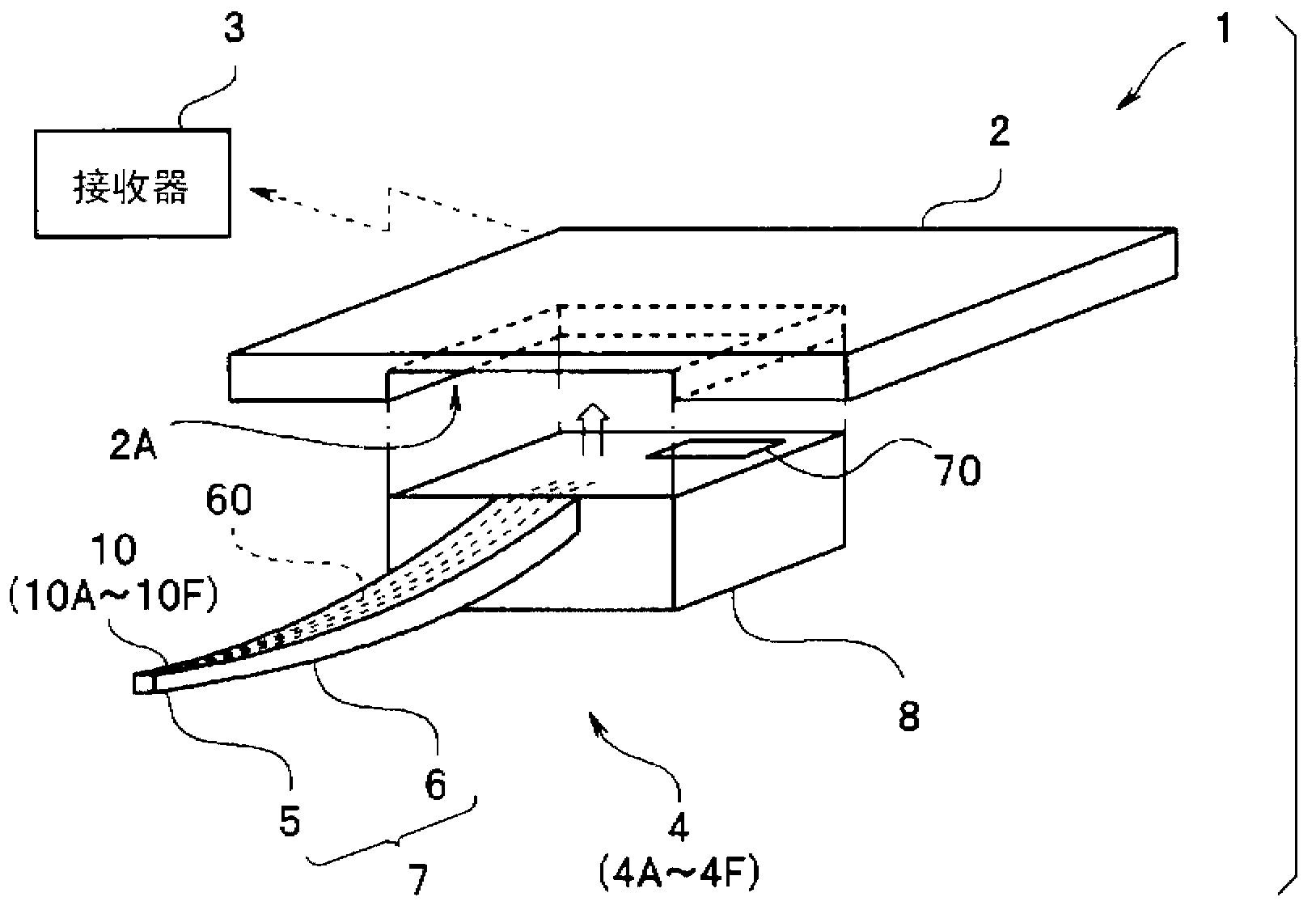

Fluorescence sensor

InactiveCN102928419ASolution to short lifeMaterial analysis by observing effect on chemical indicatorDiagnostics using fluorescence emissionAnalyteElectric signal

A fluorescence sensor 10 includes a silicon substrate 11 on which a PD element 12 that converts fluorescence into an electric signal is formed, an LED substrate 15 having a first principal plane 15A on which an LED element 15C that generates excitation light is formed, a reflective film 20 that averages a light amount distribution of the excitation light radiated from a second principal plane 15B of the LED substrate 15, and an indicator layer 17 that receives the excitation light averaged by the reflective film 20 and generates the fluorescence having a light amount corresponding to an analyte amount.

Owner:TERUMO KK

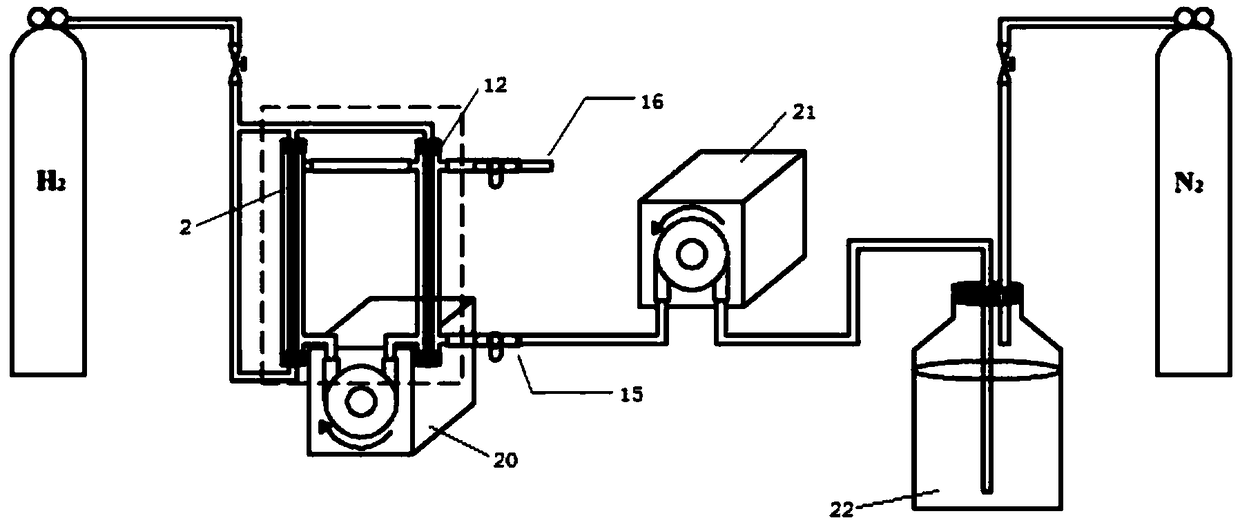

Hydrogen substrate biological Pd reactor performing aeration with no-pore hollow fiber membrane

InactiveCN108996698AAvoid churnPrevent overflowWater/sewage treatment by reductionBiological water/sewage treatmentFiberHollow fibre membrane

The invention relates to a hydrogen substrate biological Pd reactor performing aeration with a no-pore hollow fiber membrane. The hydrogen substrate biological Pd reactor comprises a main reactor anda side reactor, wherein the main reactor comprises a main reactor pipe body, a first no-pore hollow fiber membrane assembly which is arranged in the main reactor pipe body along the main reactor pipebody and to which biological Pd is adhered, and first hydrogen gas inlets which are formed in the upper end and the lower end of the first no-pore hollow fiber membrane assembly; the side reactor comprises a side reactor pipe body, a second no-pore hollow fiber membrane assembly which is arranged in the side reactor pipe body along the side reactor pipe body and to which the biological Pd is adhered, and a second hydrogen gas inlet which is formed in the upper end of the second no-pore hollow fiber membrane assembly; and the main reactor and the side reactor form circular connection and are communicated with an external hydrogen gas source and a water supply system. Compared with the prior art, the hydrogen substrate biological Pd reactor disclosed by the invention is reasonable in structure, can be used for recovering and fixing Pd elements in water, and can control the hydrogen gas supply quantity; and the treatment effect is good, the utilization rate of the hydrogen gas is increased, and the situations that the diffusion of the gas is not uniform and the utilization rate of the gas is low caused by on-way resistance are avoided.

Owner:TONGJI UNIV

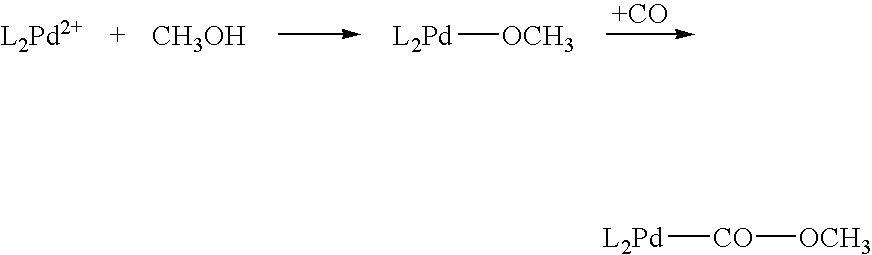

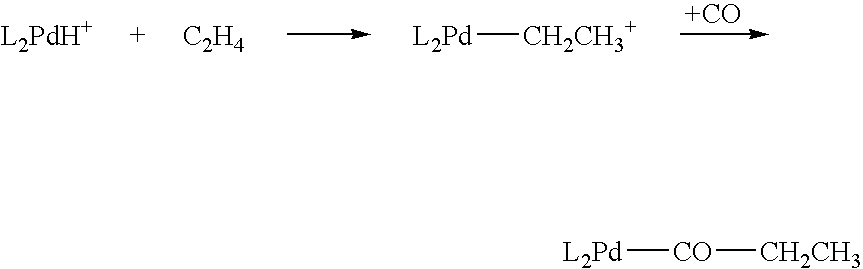

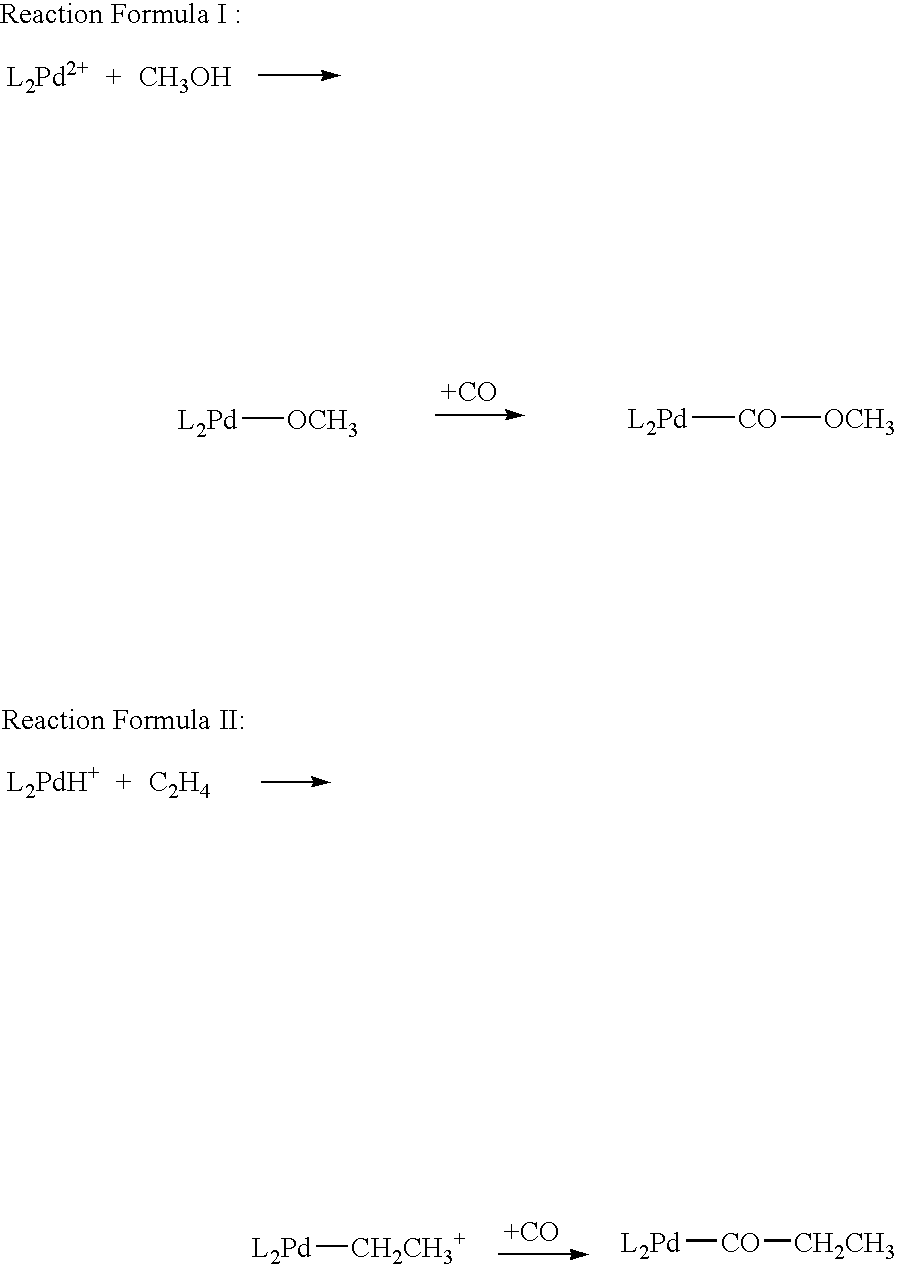

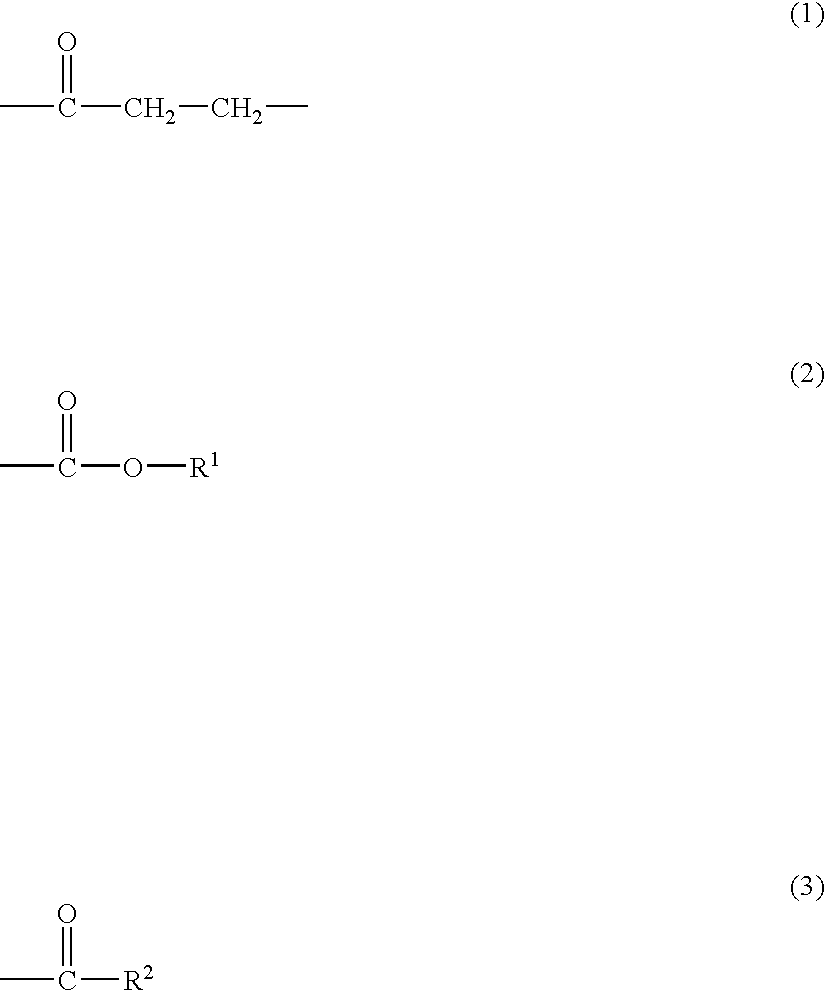

Polyketone and process for producing the same

InactiveUS20050075475A1Improve heat resistanceReduce contentPneumatic tyre reinforcementsMonocomponent synthetic polymer artificial filamentFiberPolymer science

There is provided a polyketone comprising repeating units, 95-100 mole % of which are 1-oxotrimethylene and having an intrinsic viscosity of 2.5-20 dl / g, wherein the content of Pd element is 0-20 ppm, terminal structures include an alkyl ester group (terminal group A) and an alkyl ketone group (terminal group B), and the equivalent ratio of terminal group A / terminal group B is 0.1-8.0. The polyketone of the present invention can be used in any forms, such as fibers and films, and can be applied to a wide variety of the uses such as clothing, reinforcing materials for rubbers, resins, cements, and optical fibers, electronic materials, battery materials, civil engineering materials, medical materials, daily commodities, fishery materials, and packaging materials.

Owner:ASAHI KASEI FIBERS CORPORATION

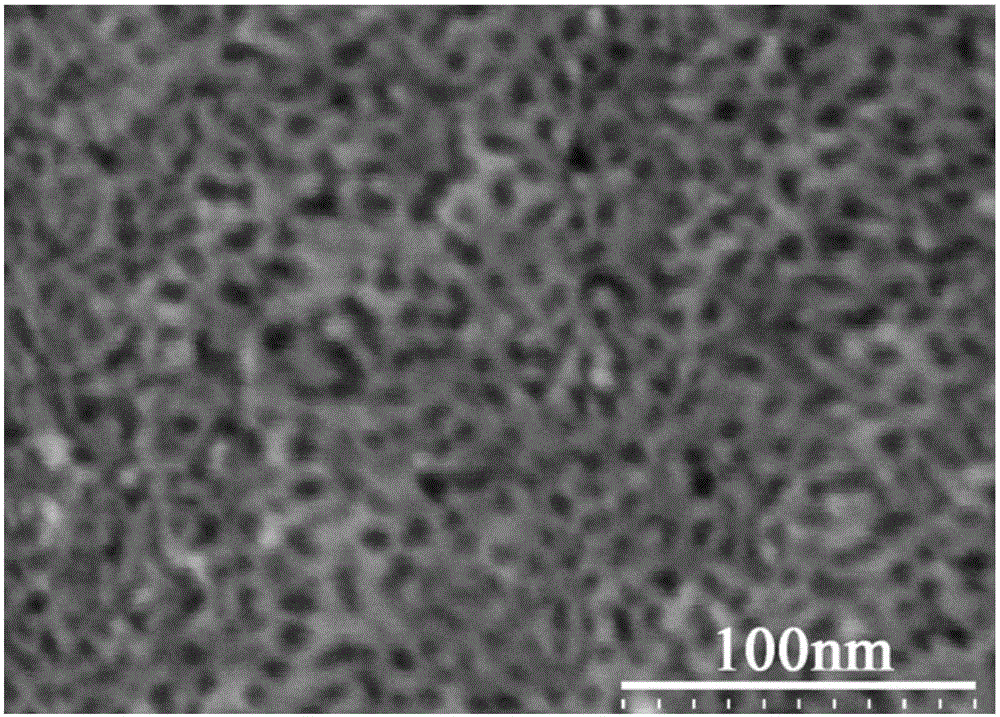

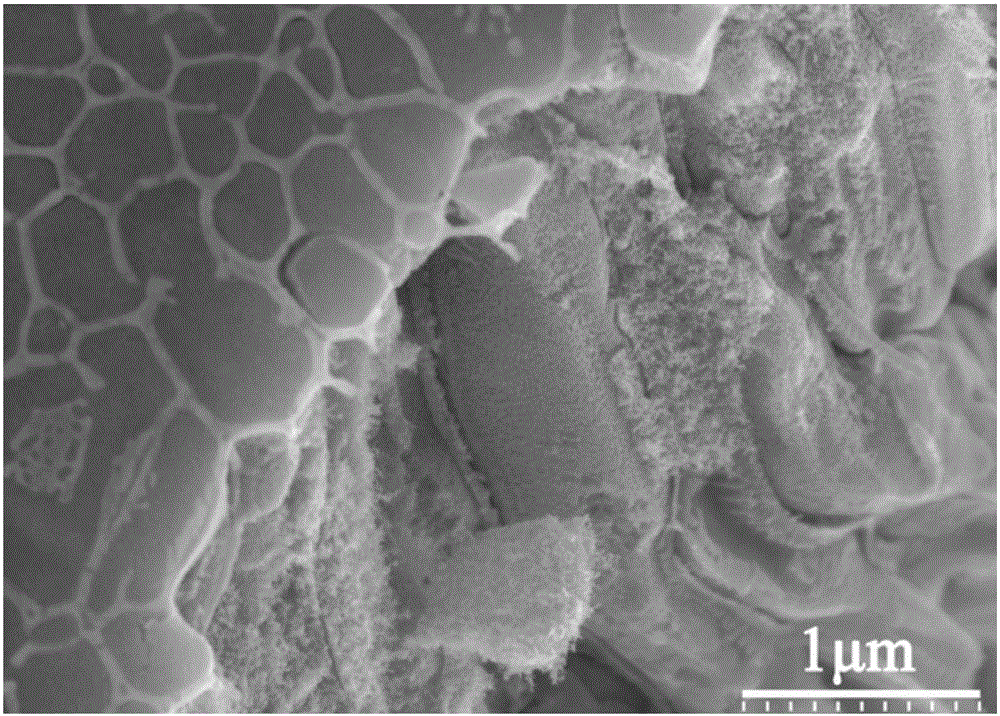

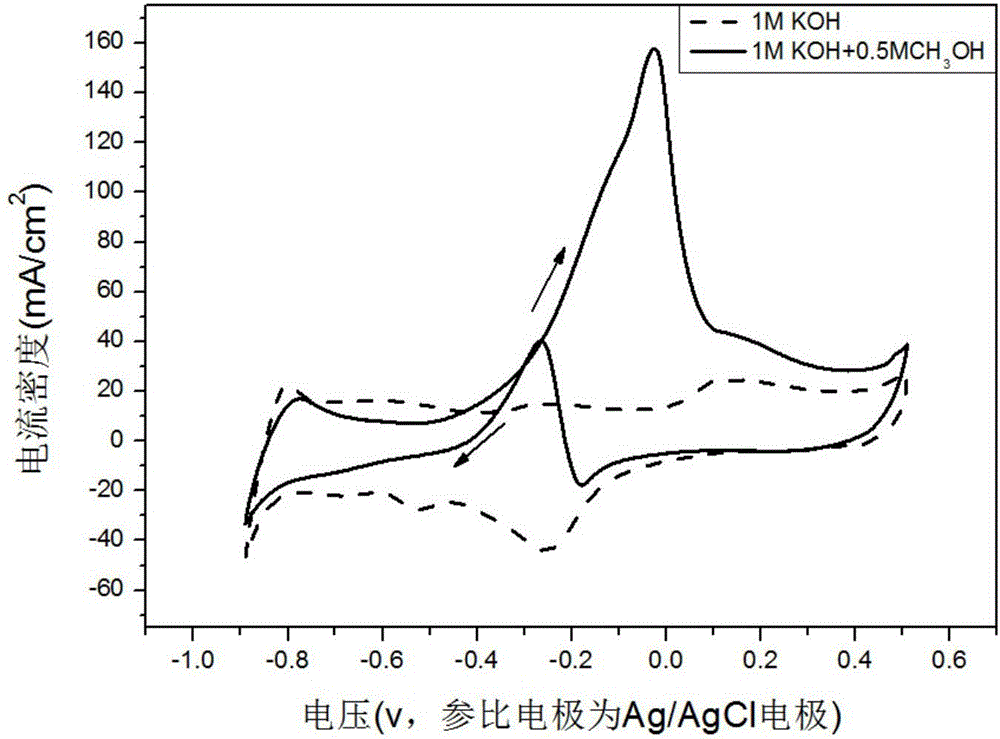

Si-containing nanometer porous Pd material and preparation method thereof

The invention discloses a Si-containing nanometer porous Pd material and a preparation method thereof and belongs to the technical field of new materials. The nanometer porous Pd material contains Cu, Si and Pd elements; the chemical constitution of alloy of a precursor of the nanometer porous Pd material is Cu<1-x-y>Pd<x>Si<y>, wherein x and y represent atomic percent, x is not smaller than 10% and not larger than 30%, and y is larger than 0% and smaller than or equal to 10%; according to difference of the alloy ingredients of the precursor, the bore diameter and the ligament diameter can be controlled between 2 to 20 nanometers. The preparation method comprises the following steps: performing non-consumed electric arc melting in combination with a water-cooling copper roller melt rapid quenching technique to prepare a Cu-Pd-Si solid solution alloy precursor wide strip material; by taking the strip material as a working electrode, performing electrochemical dealloying under a room-temperature weak acid environment to obtain the nanometer porous Pd material. The nanometer porous Pd material is low in cost, simple in preparation process, complete and free of cracks in structure and uniform and controllable in pore size, and has an excellent catalytic performance on electro-oxidation reaction of organic small molecules such as methanol in an alkaline solution. The nanometer porous Pd material can be used as an anodic reaction catalyst for a fuel battery such as alkaline ethanol or is directly used as an anode supporting material.

Owner:DALIAN UNIV OF TECH

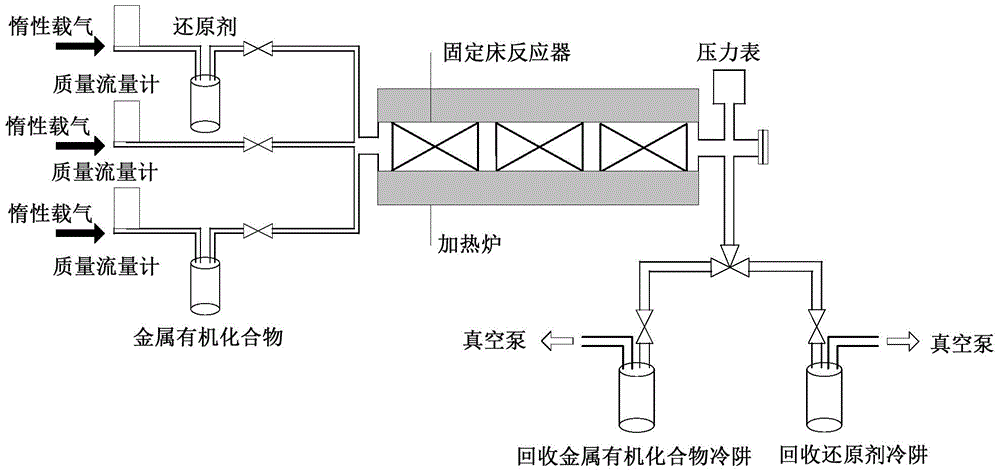

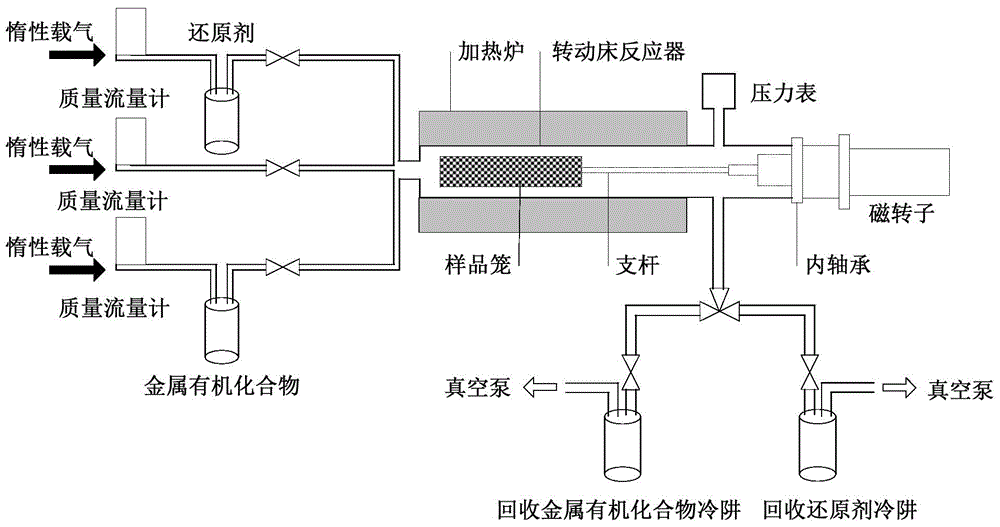

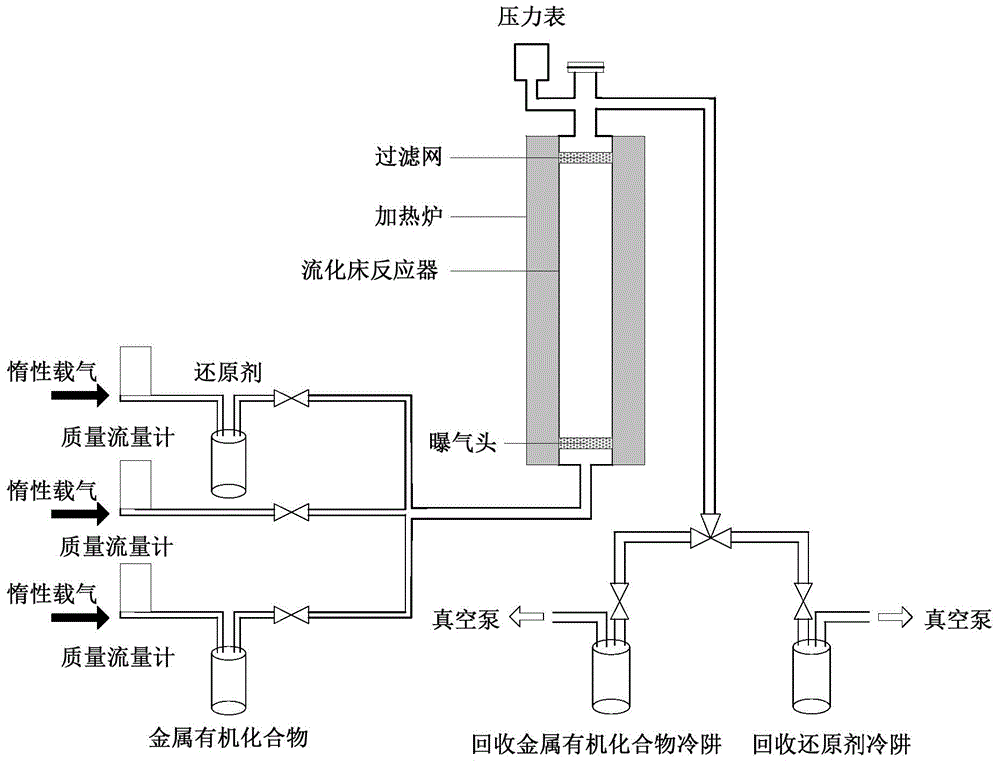

Gas-phase synthesis method for small-scale high-dispersion Pd/C catalyst

InactiveCN104437477AAvoid difficult control of the synthesis processAvoid particle agglomerationOrganic compound preparationAmino compound preparationDispersitySynthesis methods

The invention provides a gas-phase synthesis method for a small-scale high-dispersion Pd / C catalyst. According to the method, immobilization of Pd element on the carrier surface is realized by utilizing gas-solid interface reaction between Pd-containing metallo-organic compound steam and a special group on the carrier surface, and the Pd element fixed on the surface is reduced by using reducing gas. The process can be repeatedly performed according to actual demands until the Pd / C catalyst of the needed metal particle size and loading quantity is generated. The Pd nanoparticle catalyst synthesized based on a vapor phase method has the advantages of high dispersity, uniform distribution, accurately controlled particle size, dimensional stability and the like and has excellent activity, selectivity and stability in the catalytic reaction. According to the method, the defects that the synthetic process is difficult to control, the size distribution of metal particles is wide and the catalytic species is non-uniform in distribution in the traditional liquid phase impregnation-reduction method are overcome. In addition, the method is high in automation degree and simple in operating steps, the raw materials and energy consumption are saved, and large-scale production of the product is easily realized.

Owner:XIAN MODERN CHEM RES INST

Polyketone and method for producing the same

InactiveUS20060135738A1Improve heat resistanceHigh molecular weightPneumatic tyre reinforcementsMonocomponent synthetic polymer artificial filamentFiberKetone

There is provided a polyketone comprising repeating units, 95-100 mole % of which are 1-oxotrimethylene and having an intrinsic viscosity of 2.5-20 dl / g, wherein the content of Pd element is 0-20 ppm, terminal structures include an alkyl ester group (terminal group A) and an alkyl ketone group (terminal group B), and the equivalent ratio of terminal group A / terminal group B is 0.1-8.0. The polyketone of the present invention can be used in any forms, such as fibers and films, and can be applied to a wide variety of the uses such as clothing, reinforcing materials for rubbers, resins, cements, and optical fibers, electronic materials, battery materials, civil engineering materials, medical materials, daily commodities, fishery materials, and packaging materials.

Owner:TANIGUCHI RYU +2

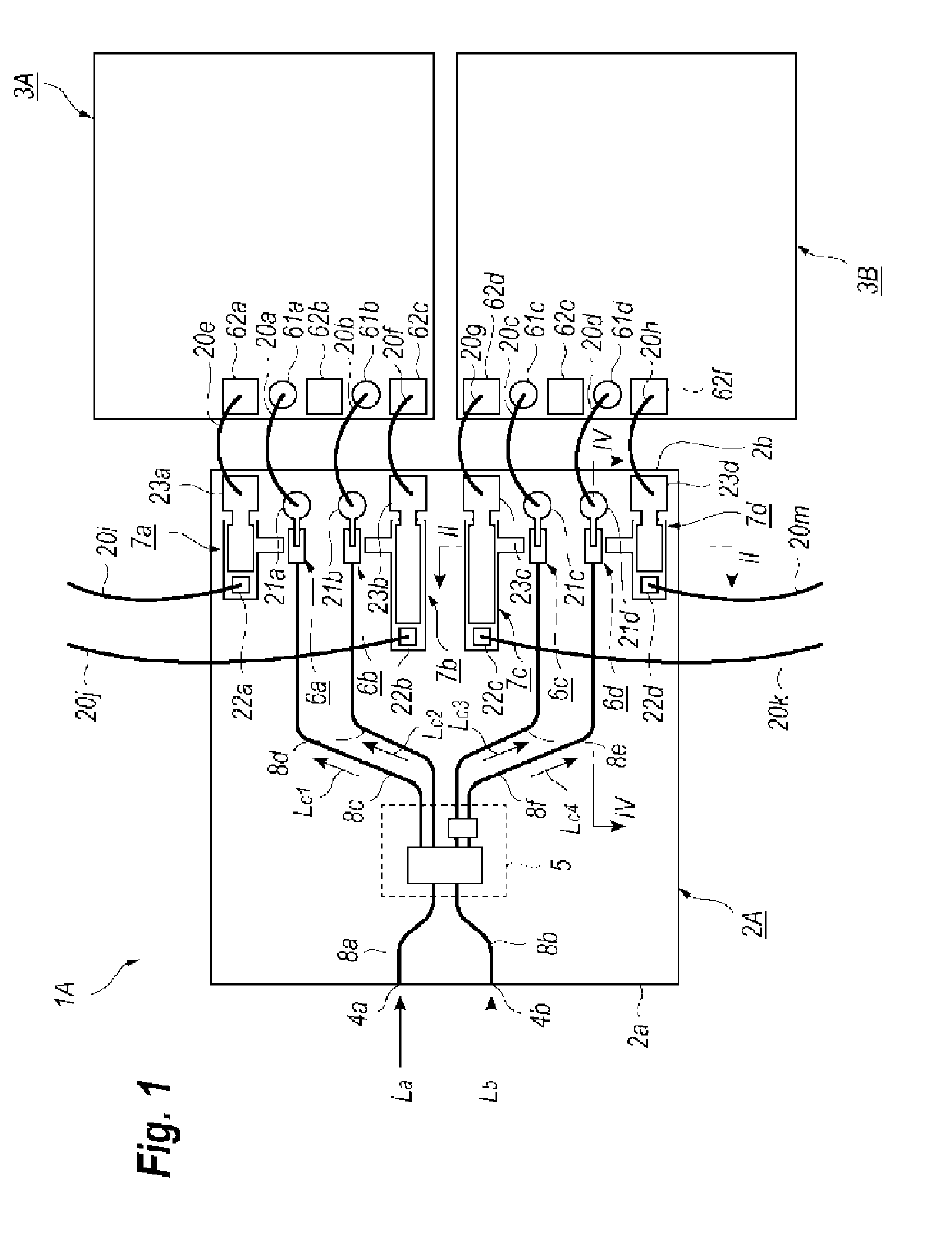

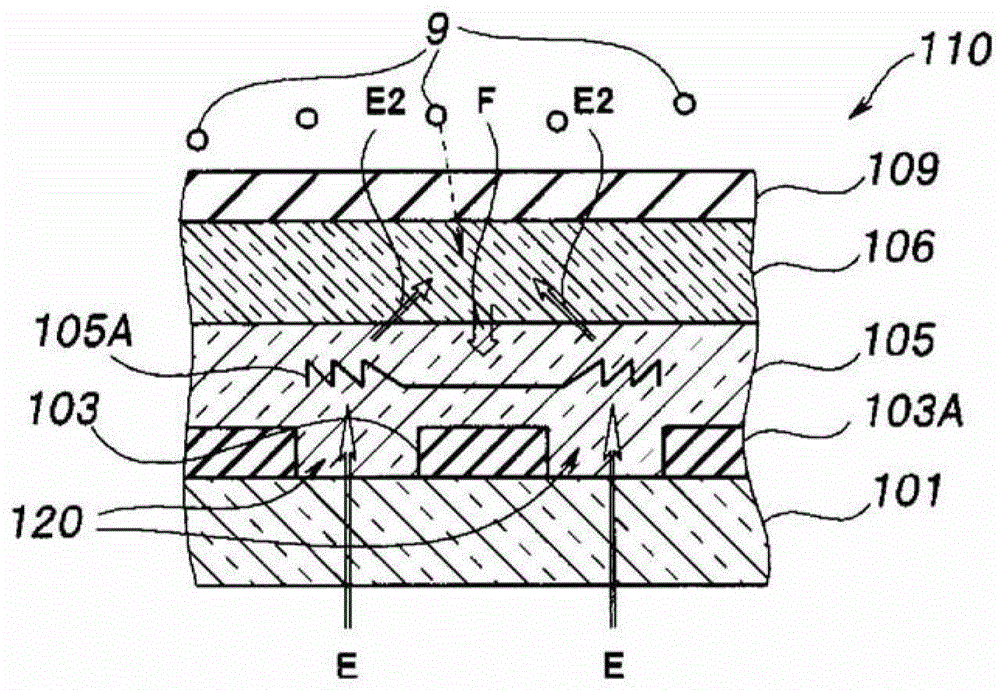

Photodiode device monolithically integrating waveguide element with photodiode element type of optical waveguide

A photodiode (PD) device that monolithically integrates a PD element with a waveguide element is disclosed. The PD device includes a conducting layer with a first region and a second region next to the first region, where the PD element exists in the first region, while, the waveguide element exists in the second region and optically couples with the PD element. The waveguide element includes a core layer and a cladding layer on the conducting layer, which forms an optical confinement structure. The PD element includes an absorption layer on the conducting layer and a p-type cladding layer on the absorption layer, which form another optical confinement structure. The absorption layer has a length at least 12 μm measured from the interface against the core layer.

Owner:SUMITOMO ELECTRIC DEVICE INNOVATIONS

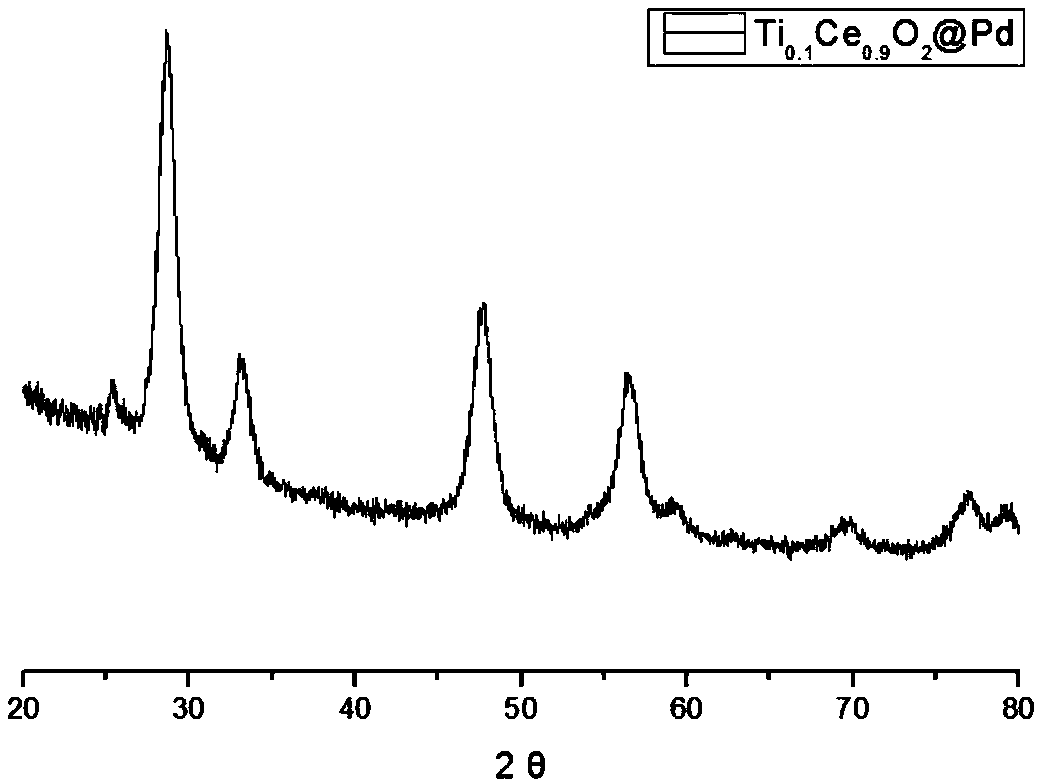

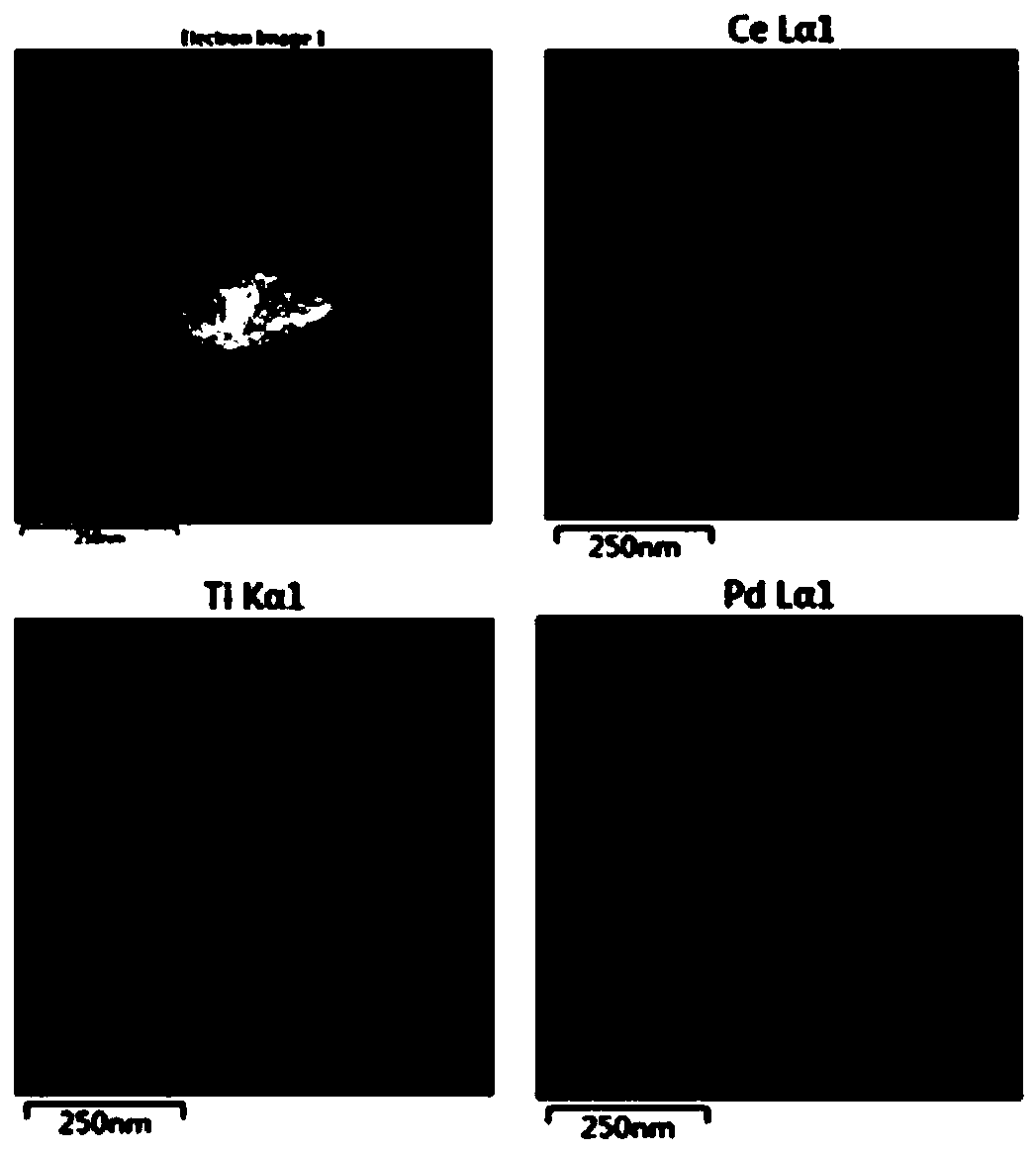

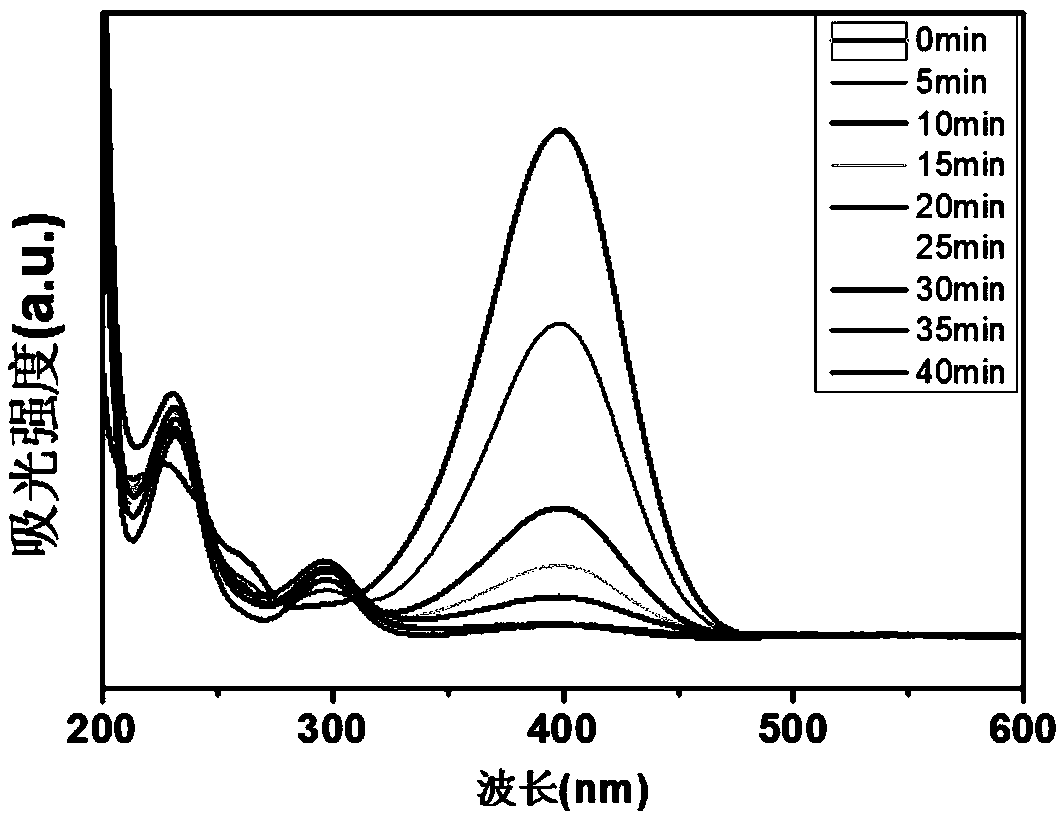

Pd-loaded Ti/CeO2 nano compound type catalyst as well as preparation method and application thereof

InactiveCN108855070ASimple production processRaw materials are easy to obtainWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsRare earthSolvent

The invention discloses a Pd-loaded Ti / CeO2 nano compound type catalyst. A Ti-doped CeO2 nanosheet is taken as a carrier, and a transition metal Pd element is loaded on the carrier, wherein the load of the Pd element is less than or equal to 0.19 wt%. The invention further discloses a preparation method of the Pd-loaded Ti / CeO2 nano compound type catalyst, the method comprises the following steps:taking ethyl alcohol as a solvent, organic acid and inorganic salt as raw materials and water as a precipitant to prepare a rare earth oxide, then taking ethanediol and the like as reducing agents, enabling Pd nano particles to be loaded on a Ti-doped CeO2 nanosheet carrier, the prepared nano material has uniform morphology, various doped elements are uniformly distributed, and the Pd-loaded Ti / CeO2 nano compound type catalyst has a good catalytic reduction effect on p-nitrophenol, high reusability and a potential application value in the sewage treatment aspect.

Owner:杭州同久净颢科技有限责任公司

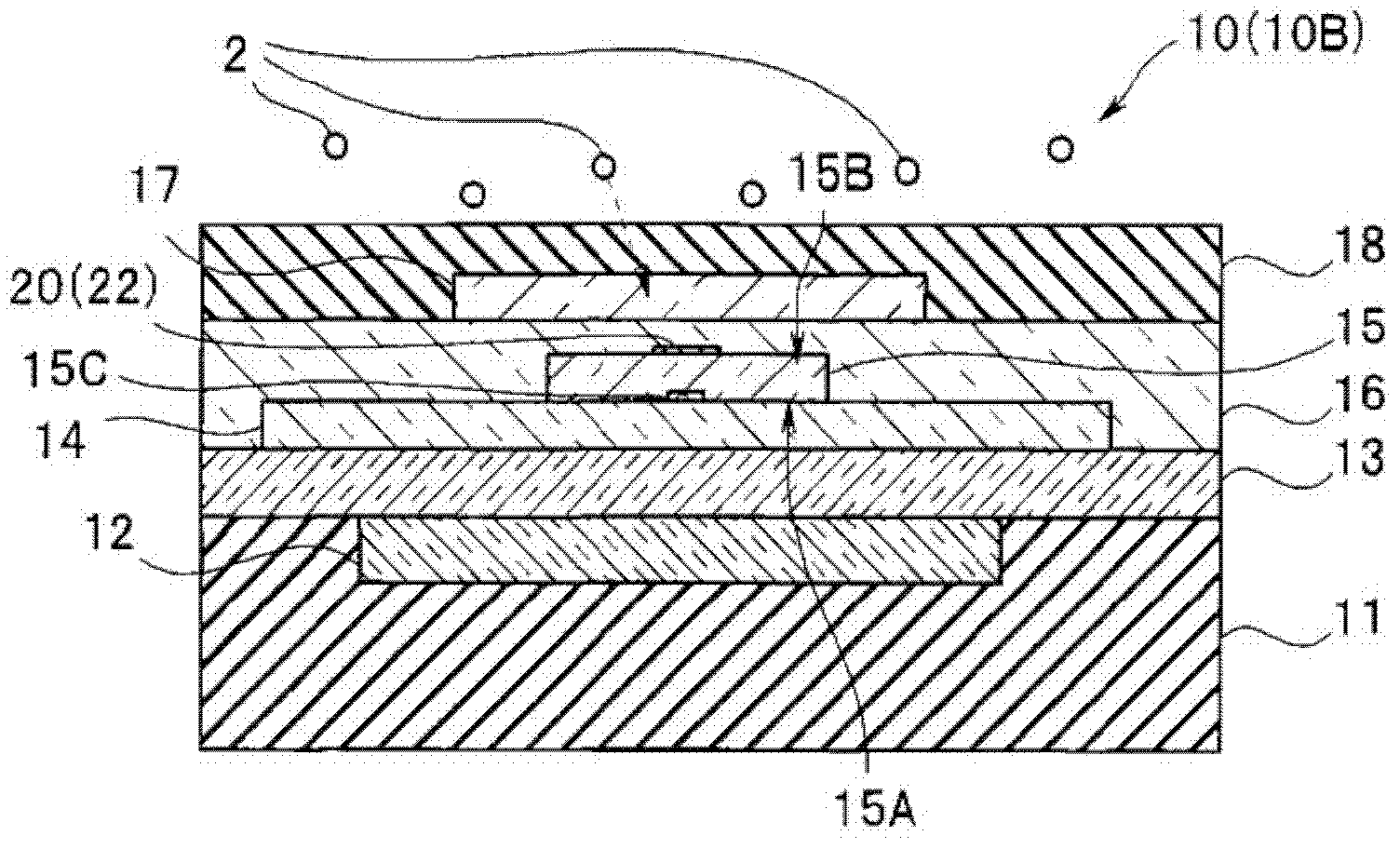

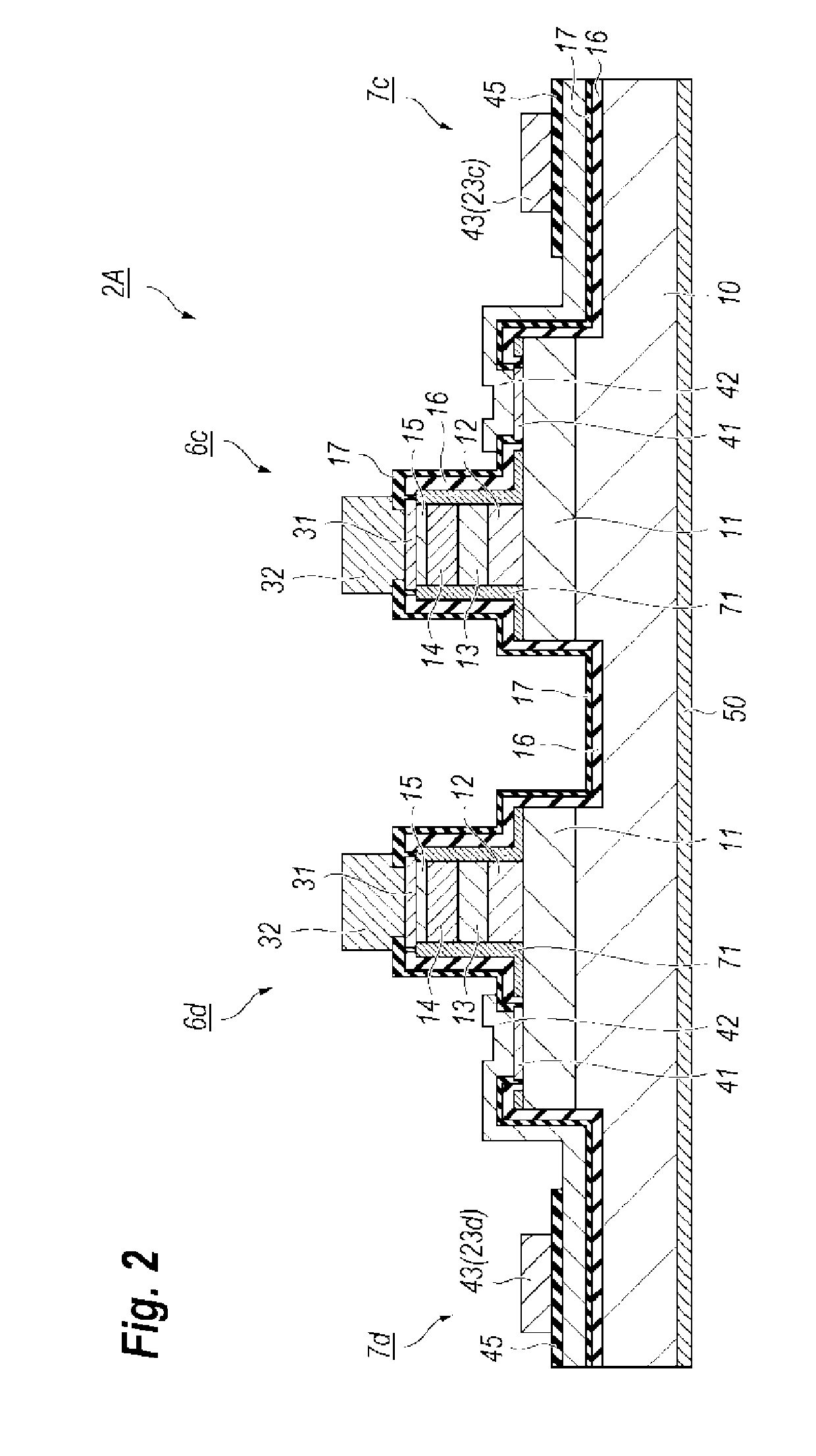

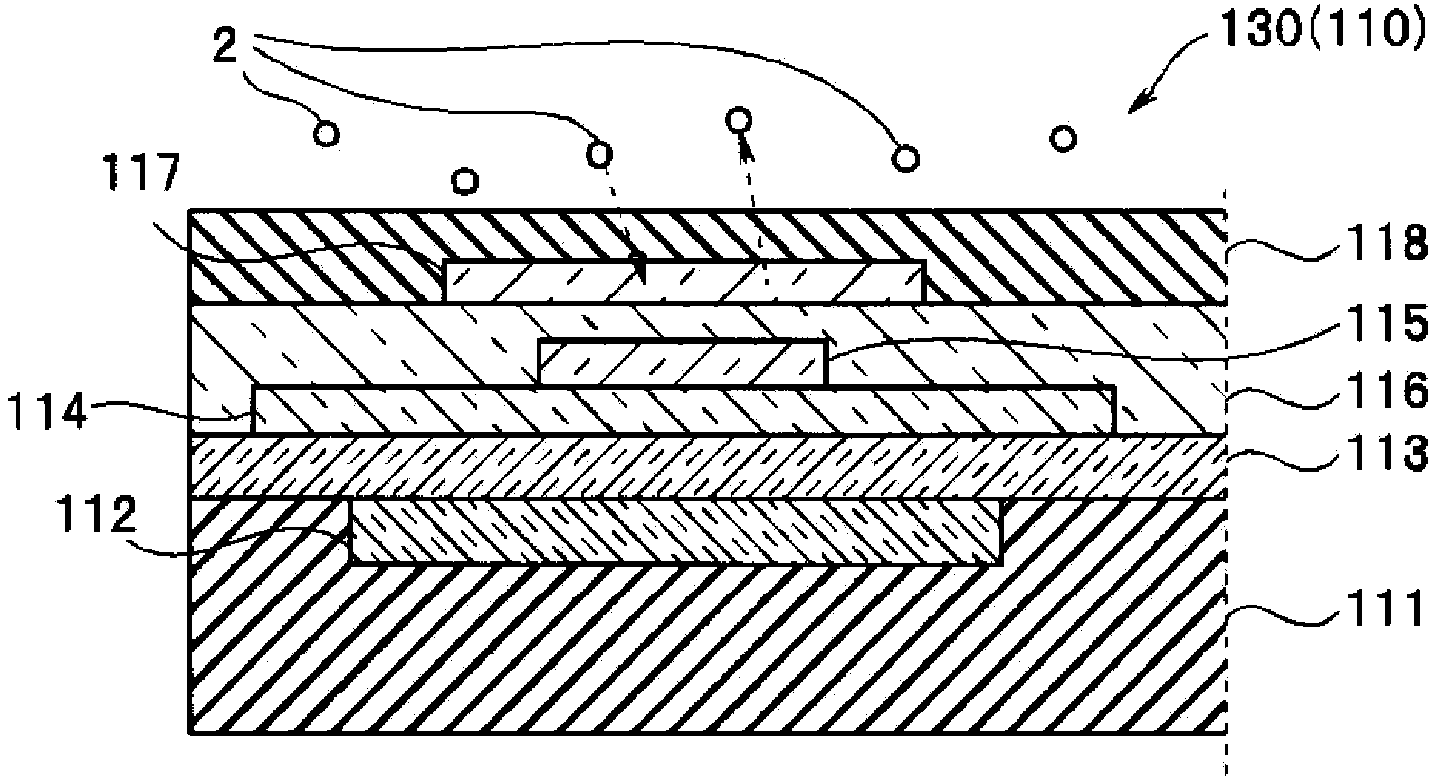

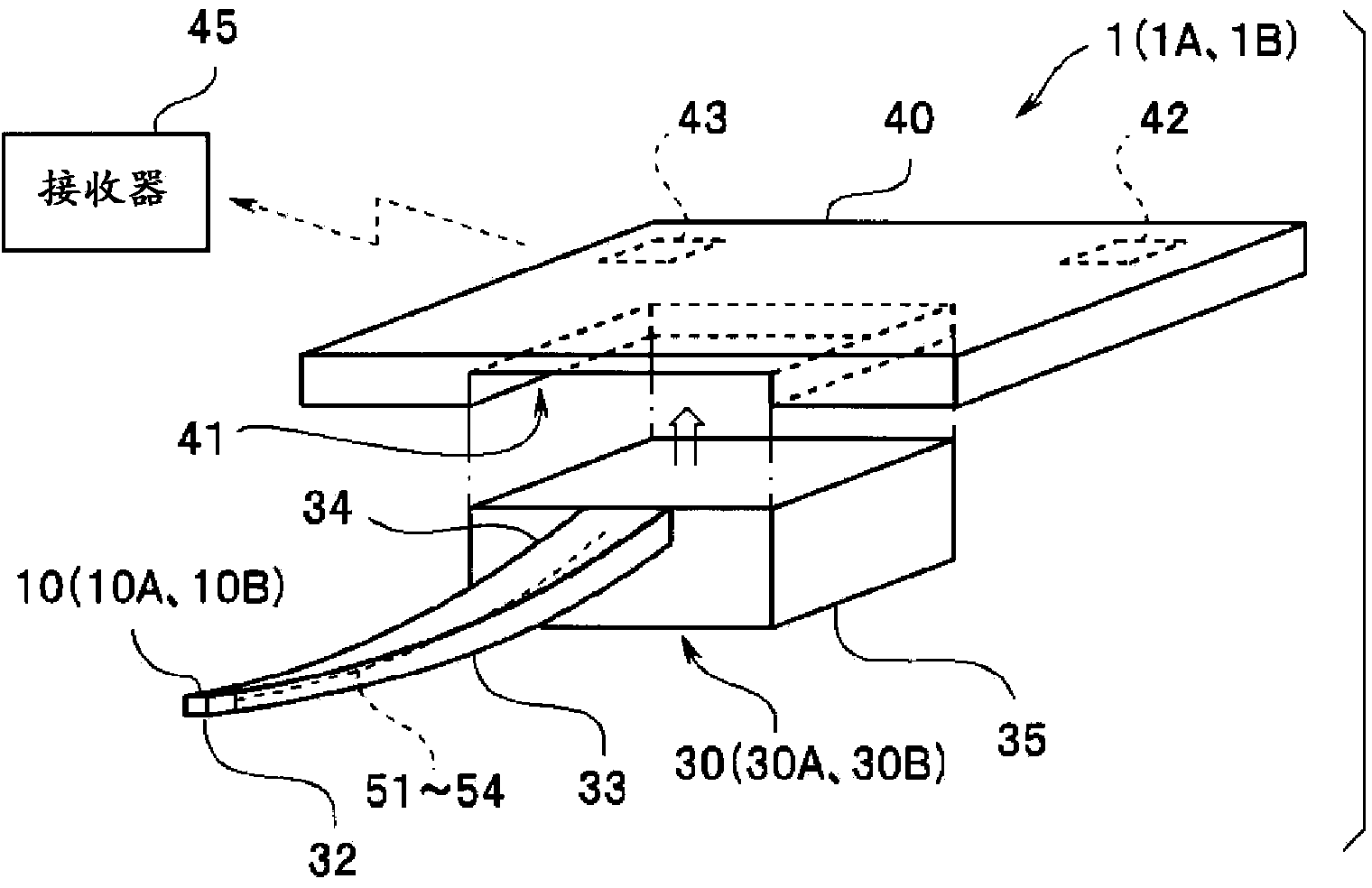

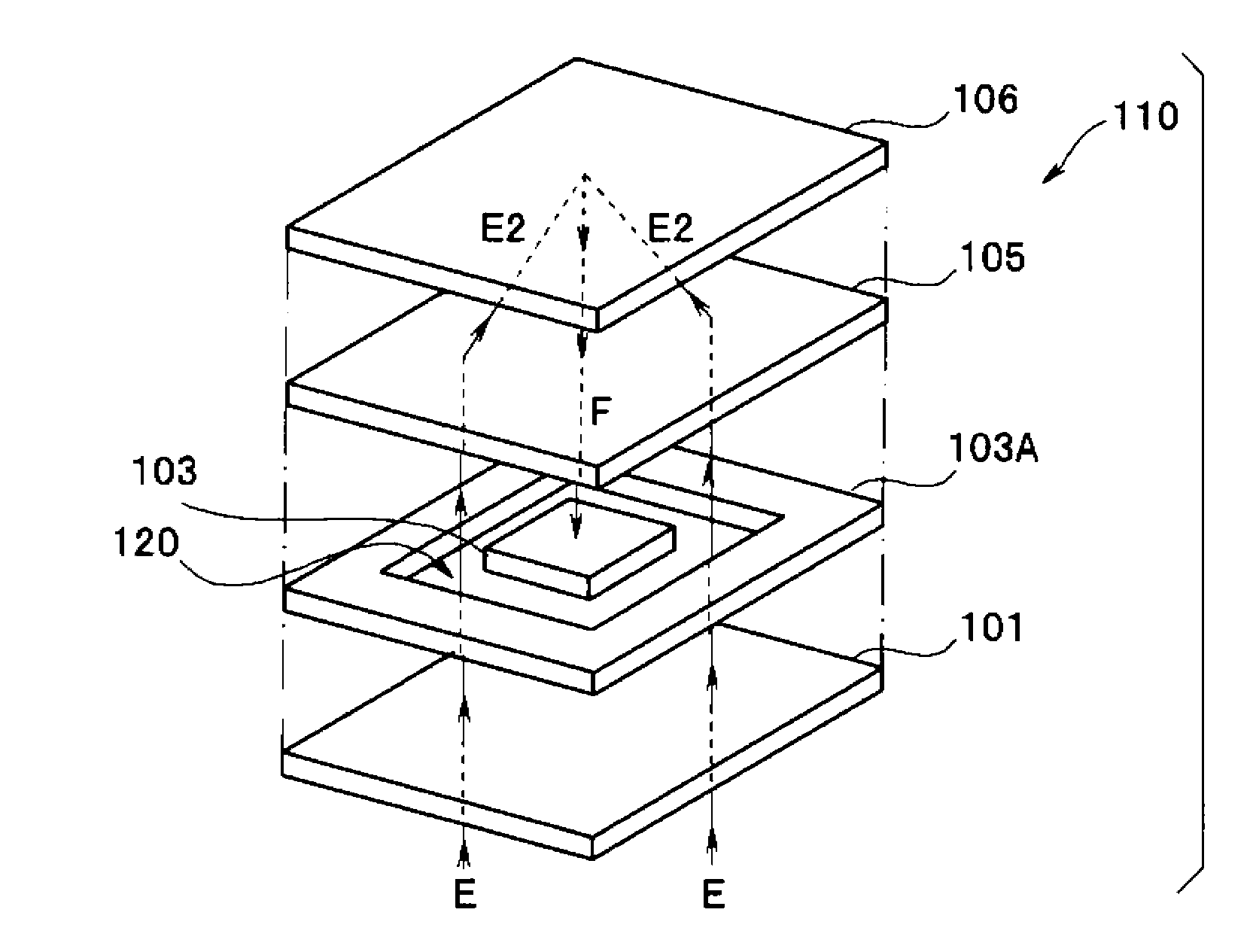

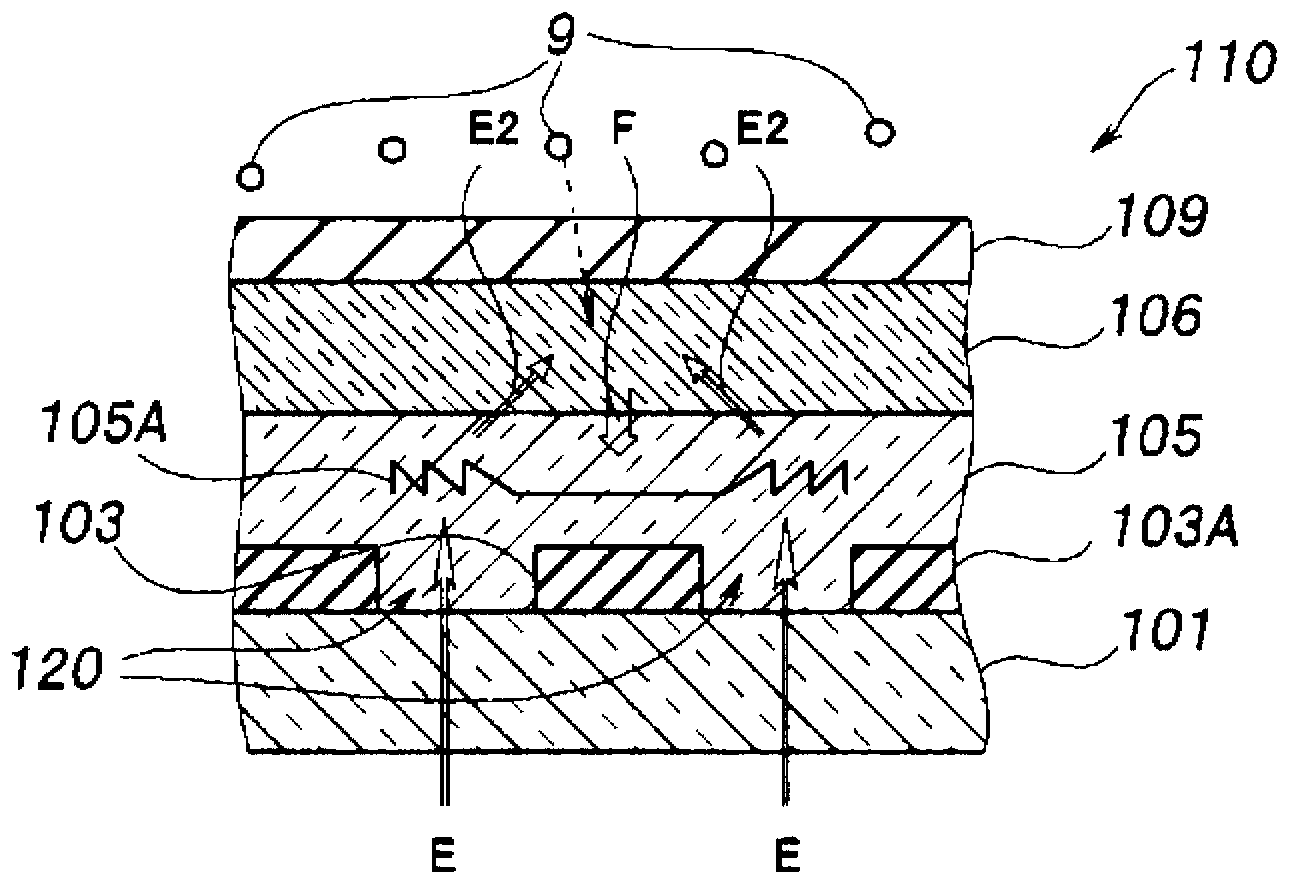

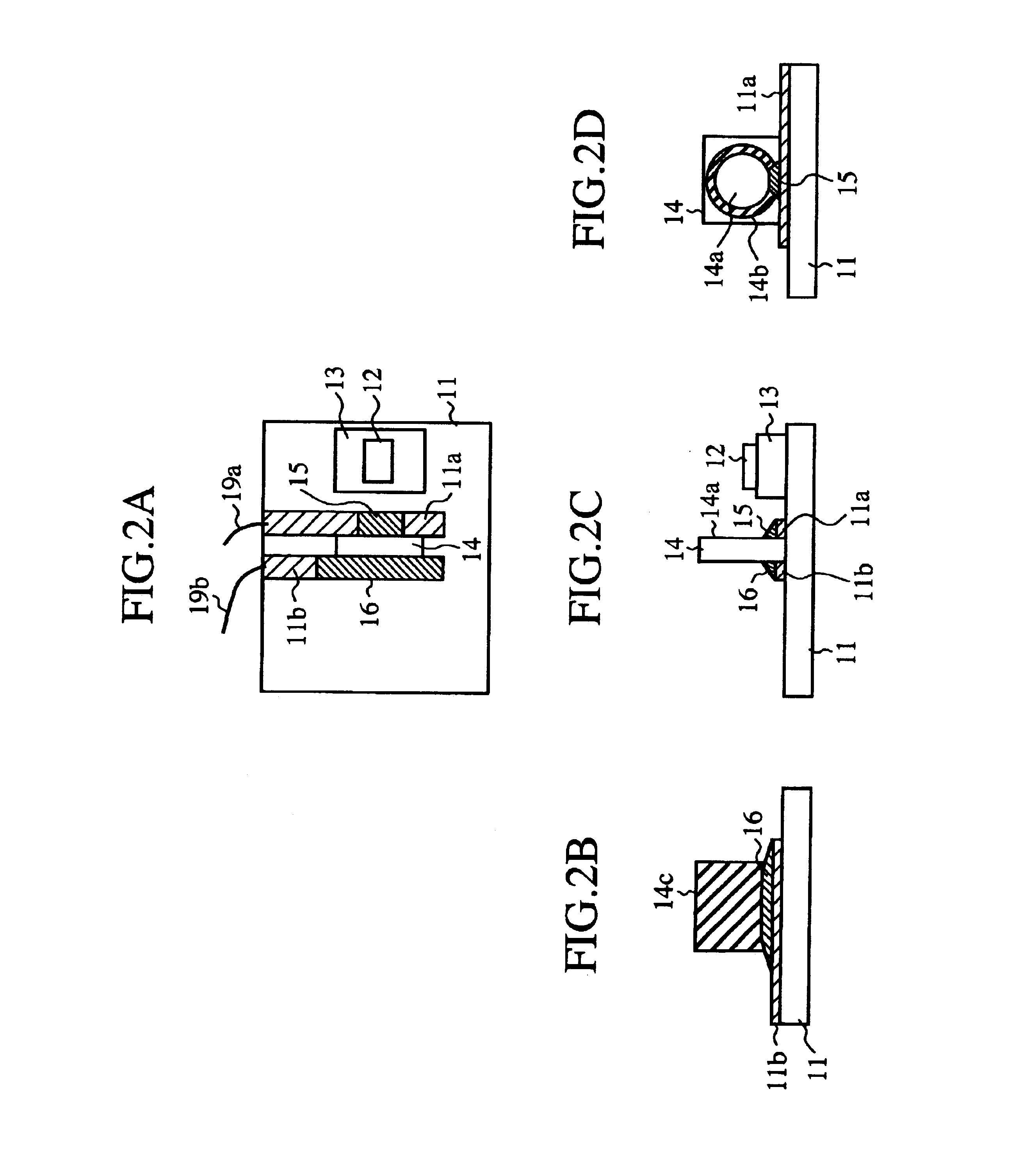

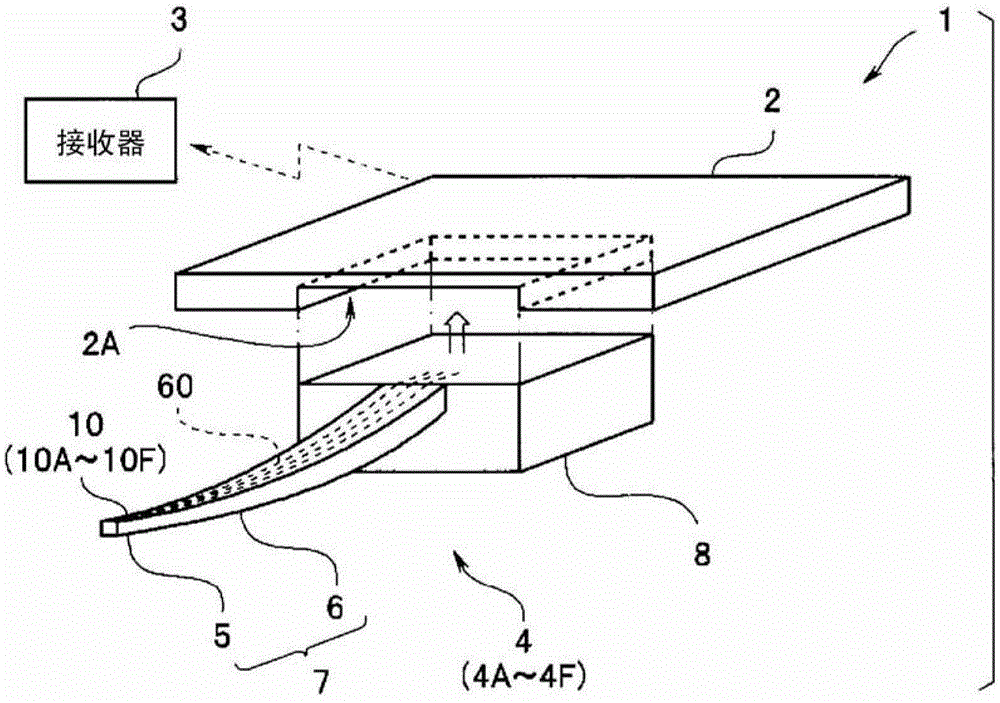

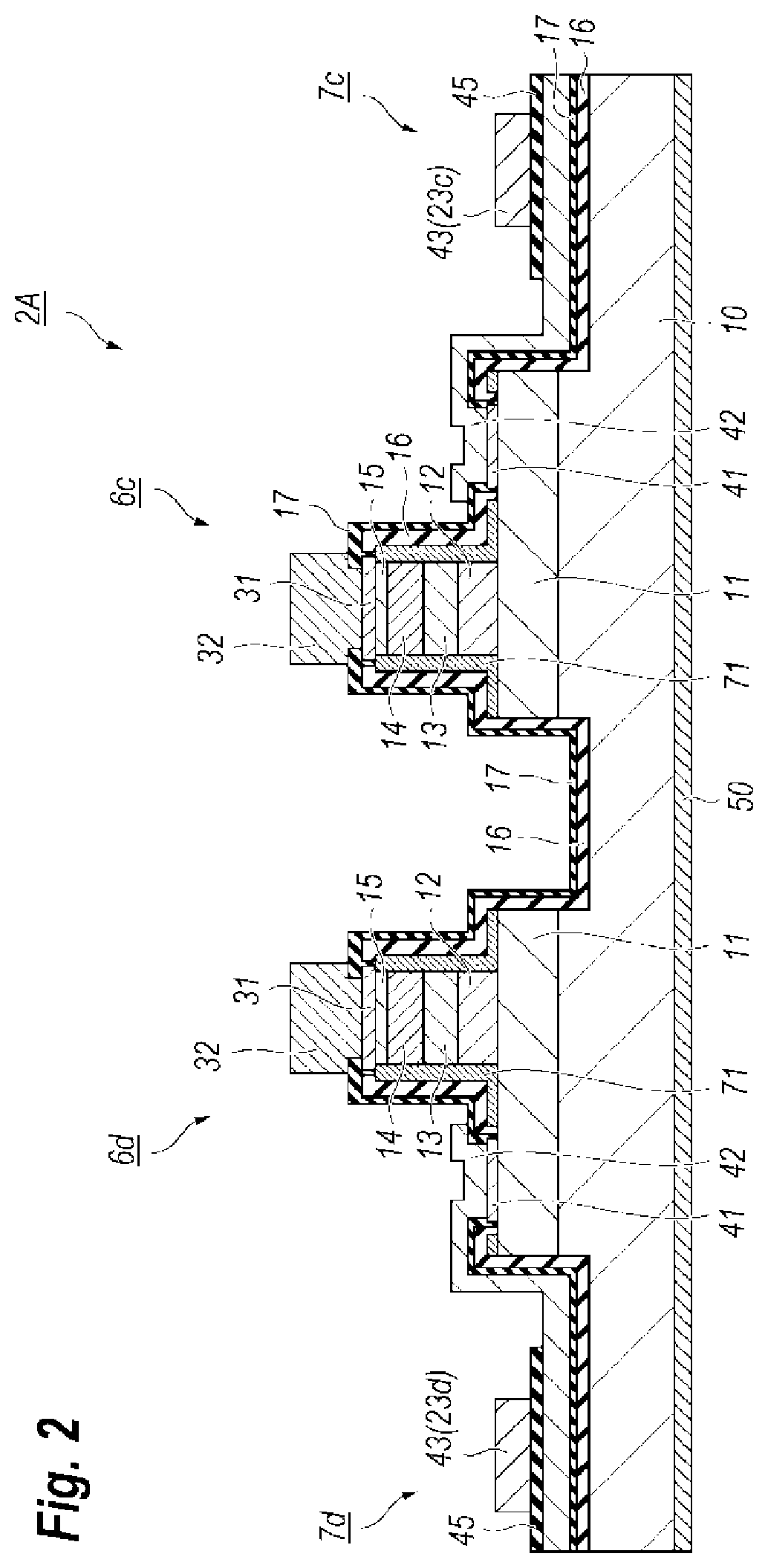

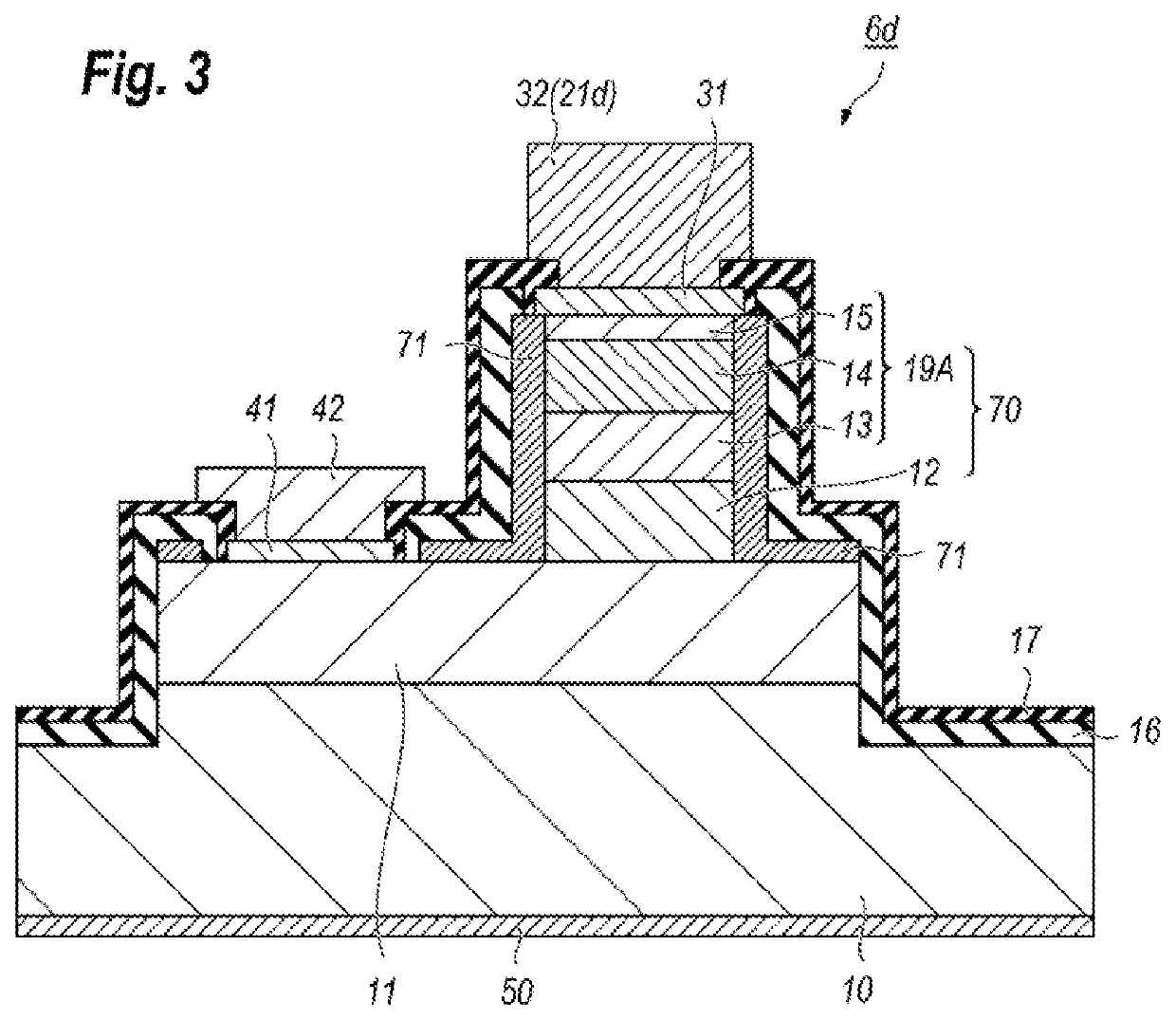

Fluorescent sensor and sensor system

ActiveCN104126113AMaterial analysis by observing effect on chemical indicatorFluorescence/phosphorescenceAnalyteElectric signal

A fluorescent sensor (30) is provided with: a detection substrate section (11), wherein a PD element (12), which converts fluorescence into electric signals, is formed on a wall surface (22) of a through hole (21) that penetrates a first main surface (11SA) and a second main surface (11SB); an indicator (17), which is disposed inside of the through hole (21), and which generates fluorescence with intensity corresponding to the concentration of an analyte when the excitation light is received; a filter layer (14), which covers the PD element (12), passes through the fluorescence, and blocks the excitation light; a light blocking layer (18), which covers an opening of the through hole (21), said opening being in the first main surface (11SA), and which the analyte can pass through; and an LED chip (15), which covers a region just below the opening of the through hole (21), said opening being in the second main surface (11SB), and which generates the excitation light.

Owner:TERUMO KK

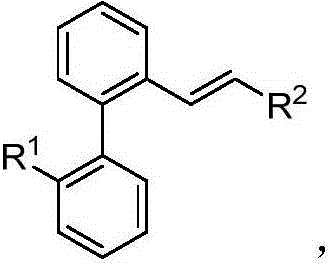

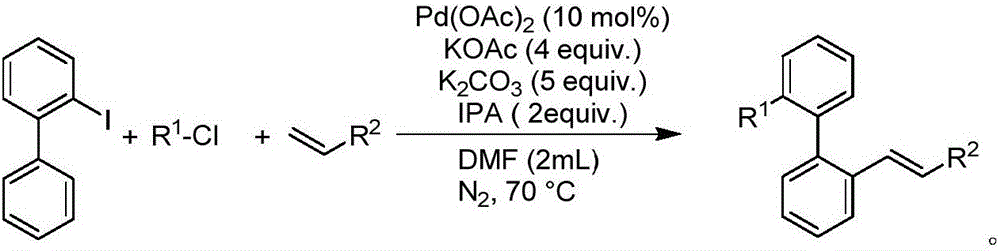

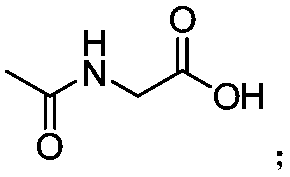

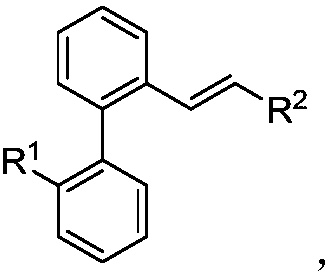

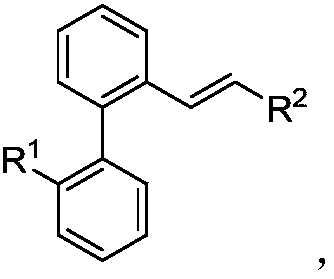

Alkyl/alkenyl-modified difunctional biphenyl compounds and preparation method thereof

InactiveCN105837388APharmaceutically activeLow yieldCarboxylic acid nitrile preparationOrganic compound preparationOrganic solventSynthesis methods

The invention relates to alkyl / alkenyl-modified difunctional biphenyl compounds and a preparation method thereof. The preparation method comprises the following step: by controlling the reaction temperature at 50-110 DEG C in an organic solvent, carrying out reaction on 2-iodobiphenyl, chloralkane and olefin by using the Pd element as a catalyst for 2-24 hours in the presence of an alkali, a reducer and additives, thereby obtaining the alkyl / alkenyl-modified difunctional biphenyl compounds. Compared with the prior art, the synthesis method of the alkyl / alkenyl-modified difunctional biphenyl compounds is completed for the first time. The method has the advantages of mild conditions, high yield, wide substrate application range and the like, and is simple to operate.

Owner:TONGJI UNIV

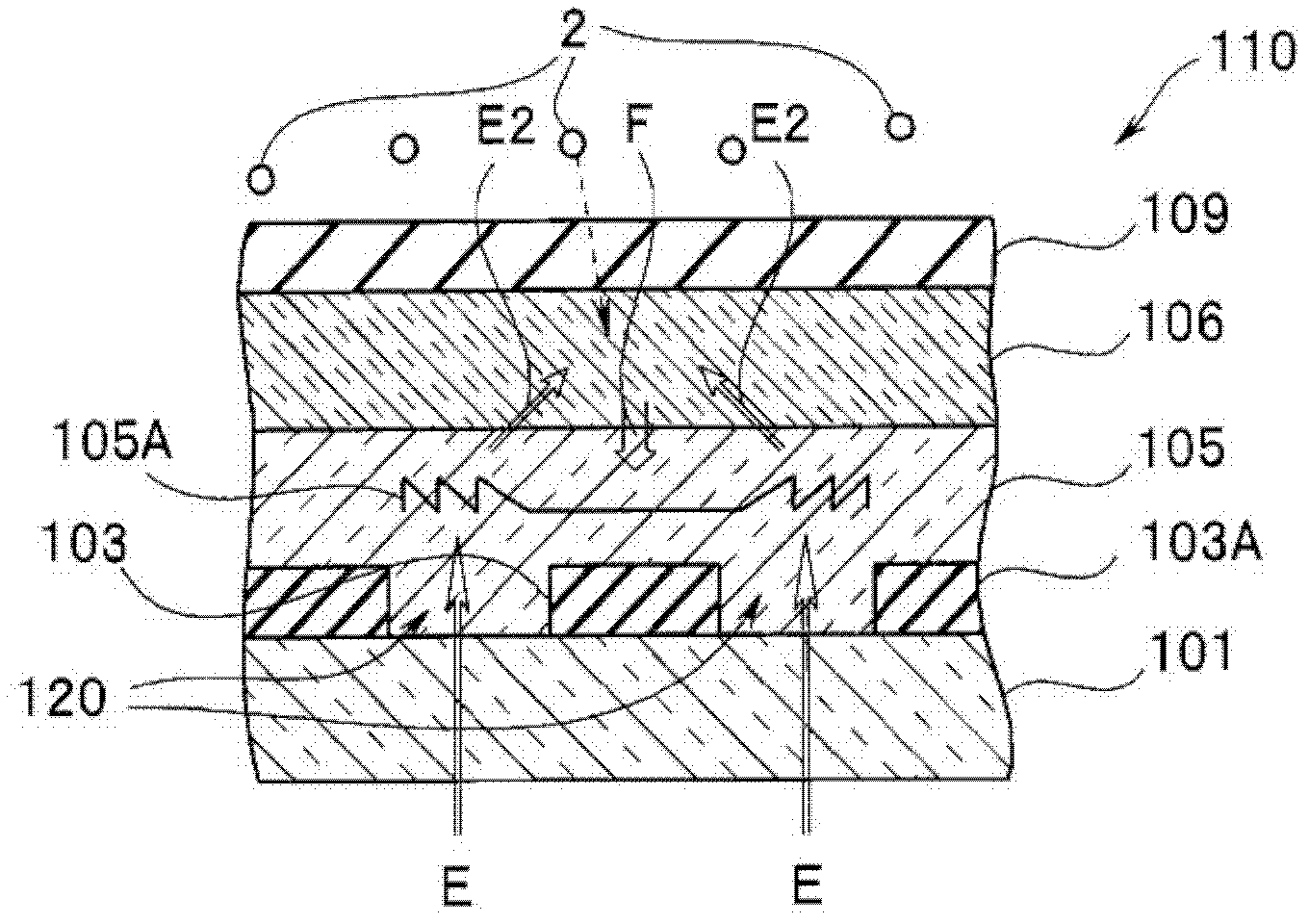

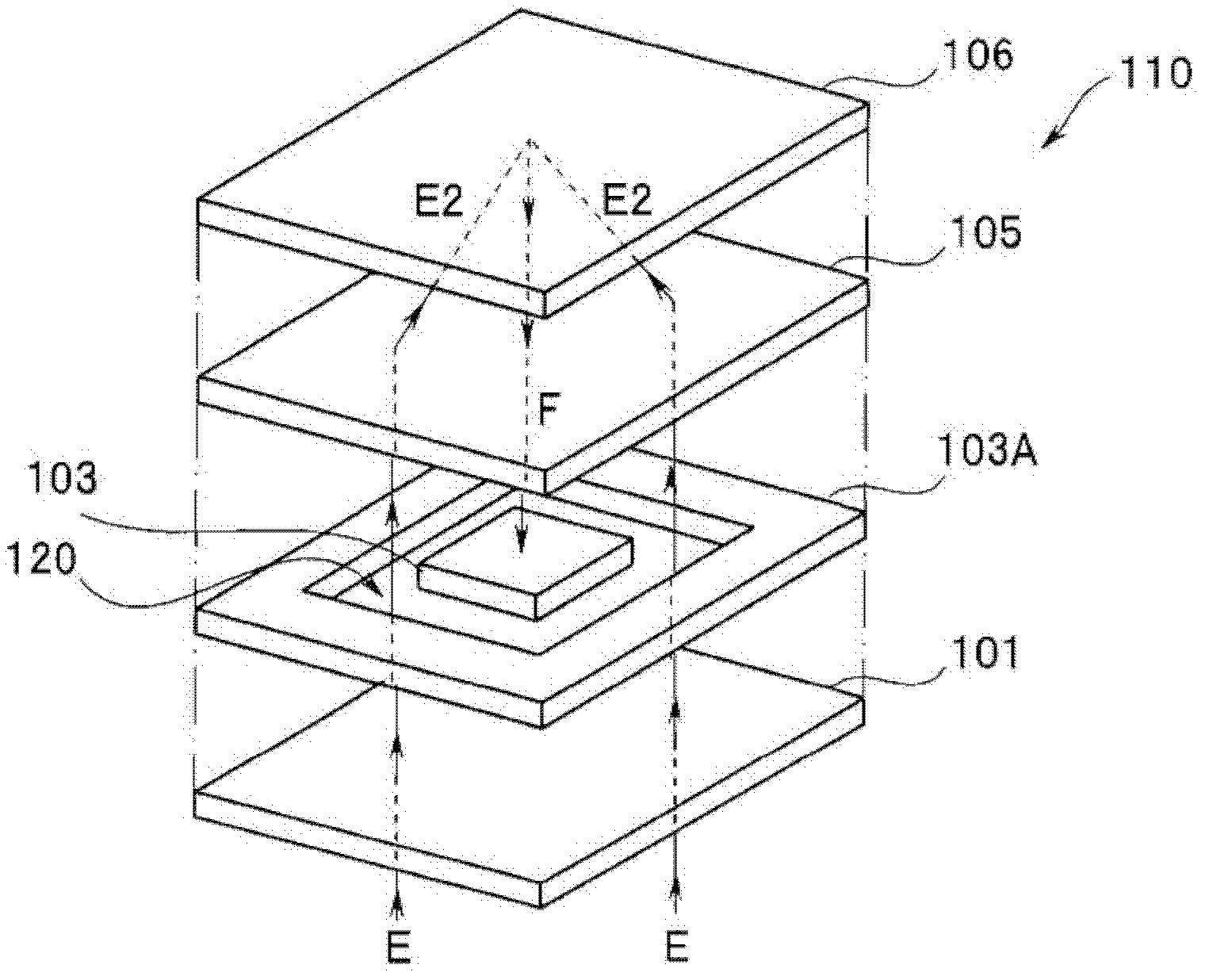

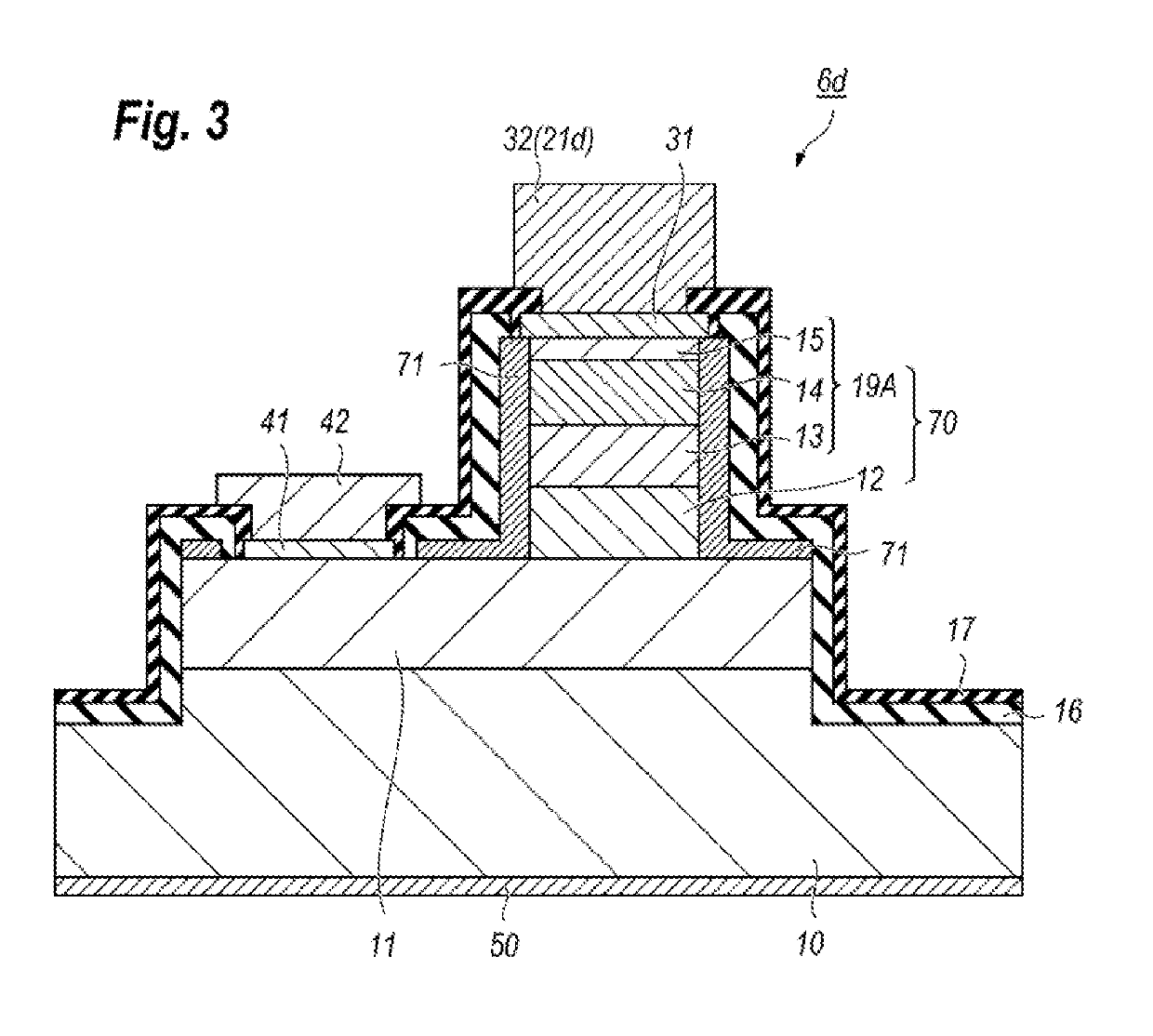

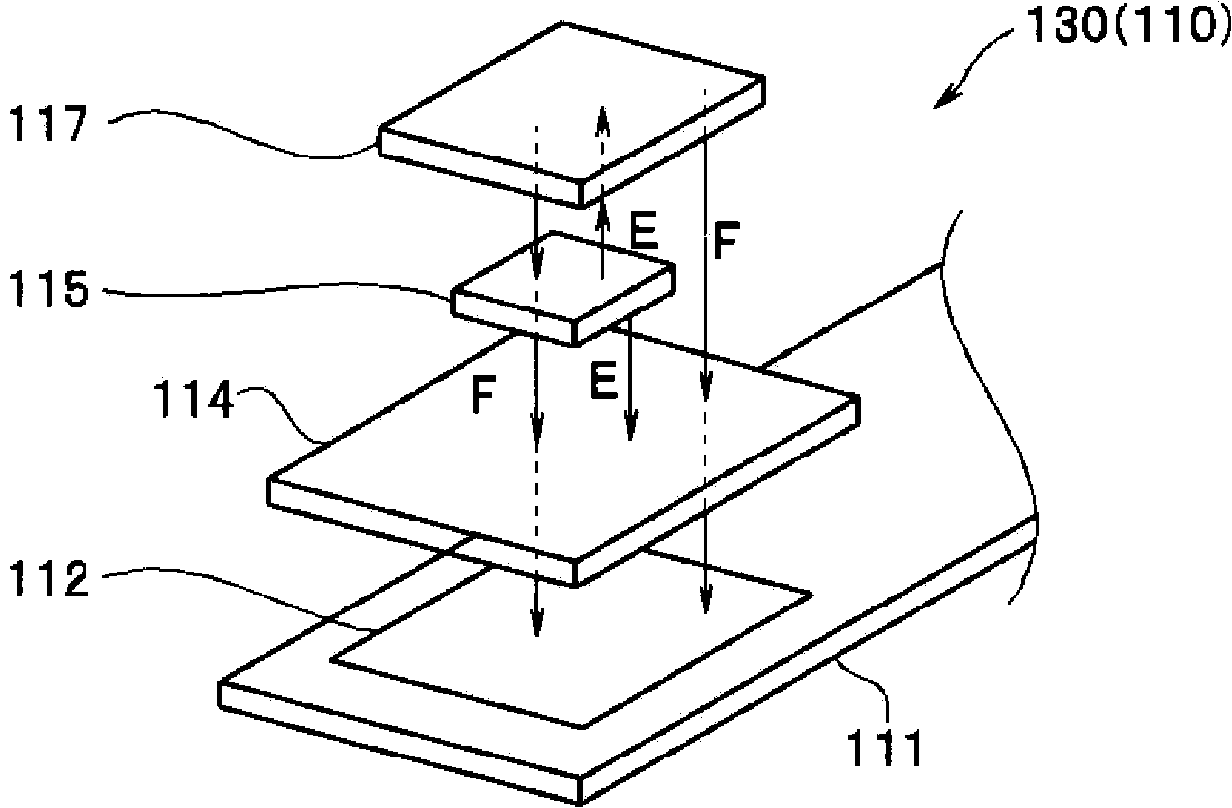

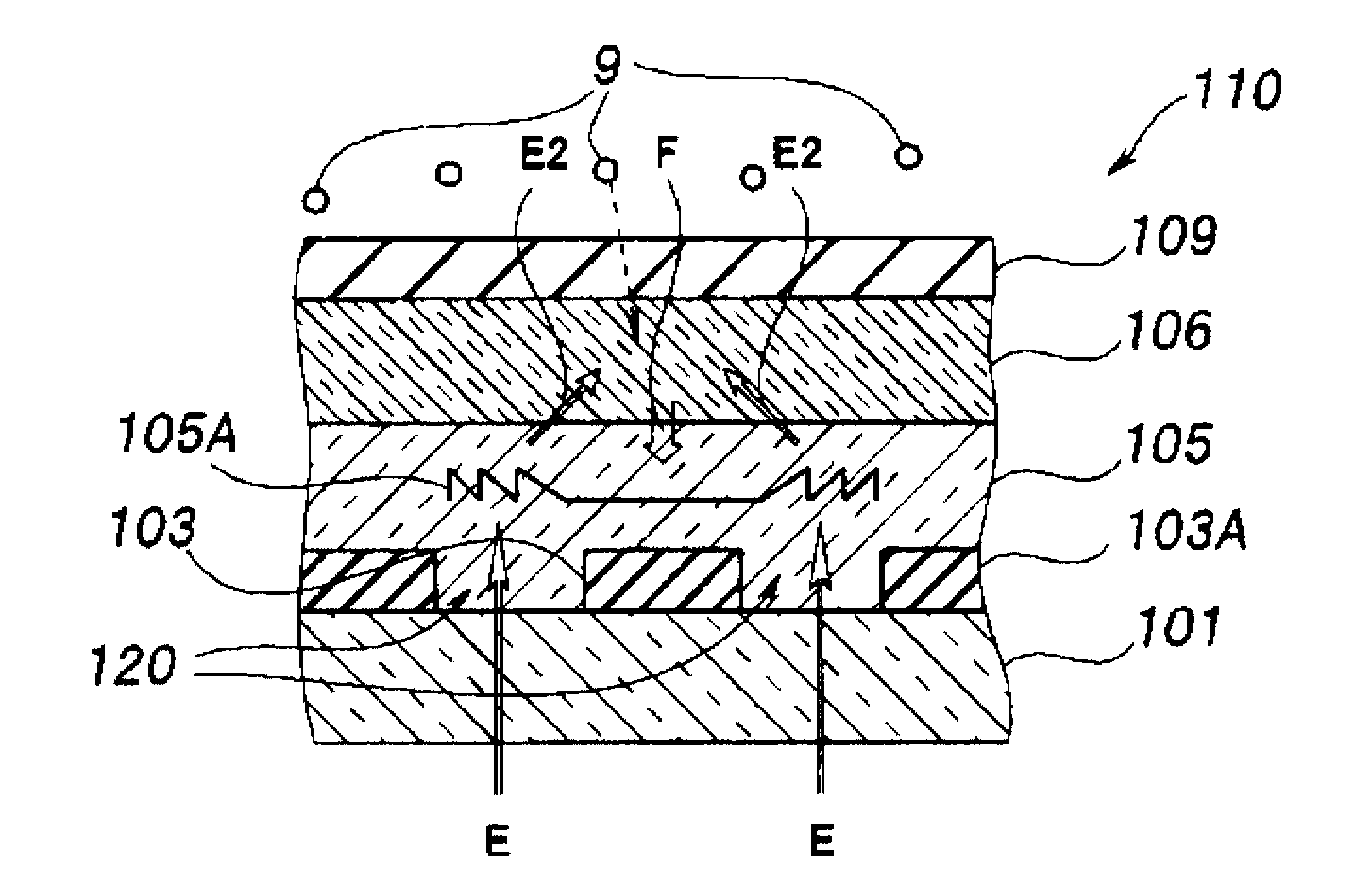

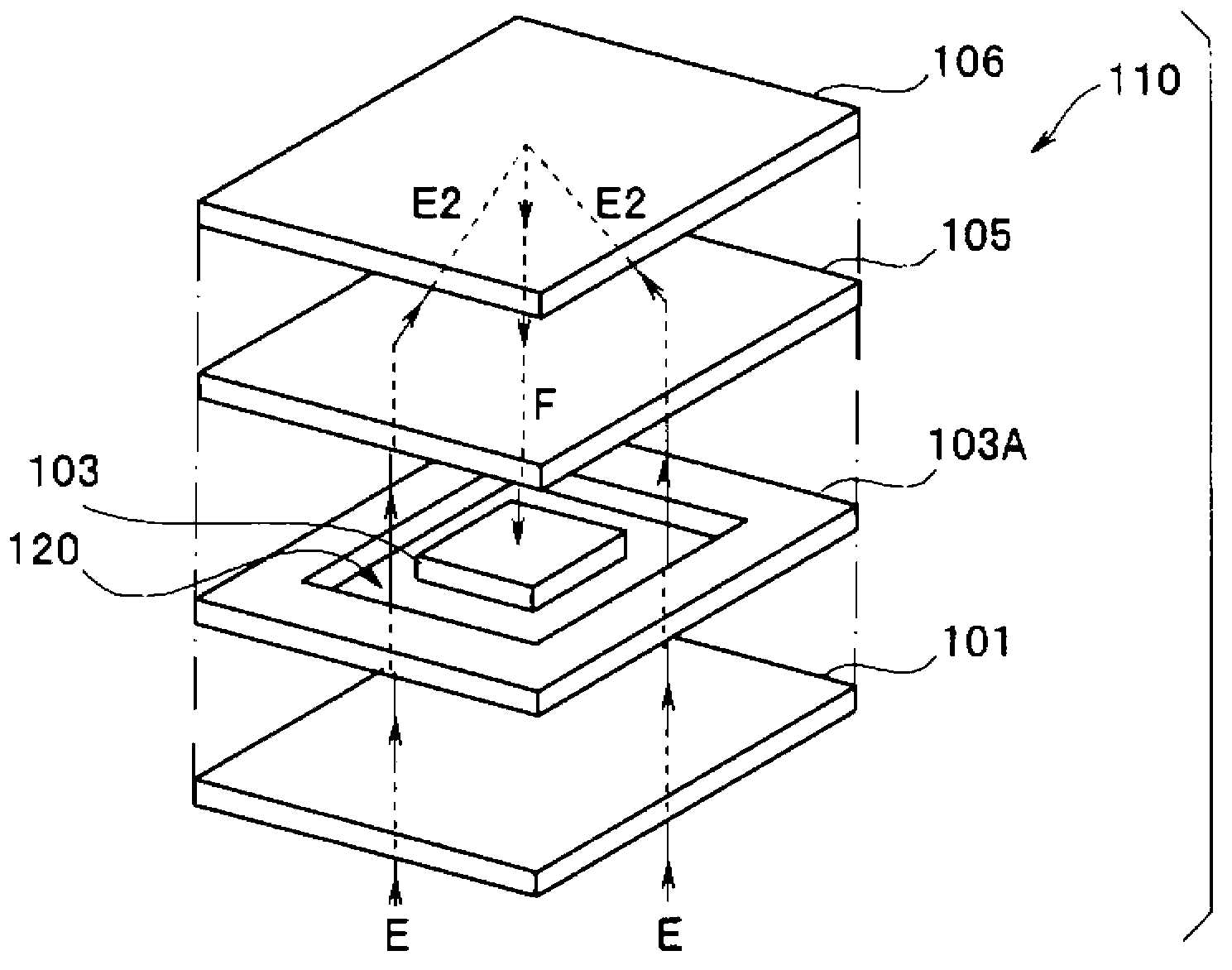

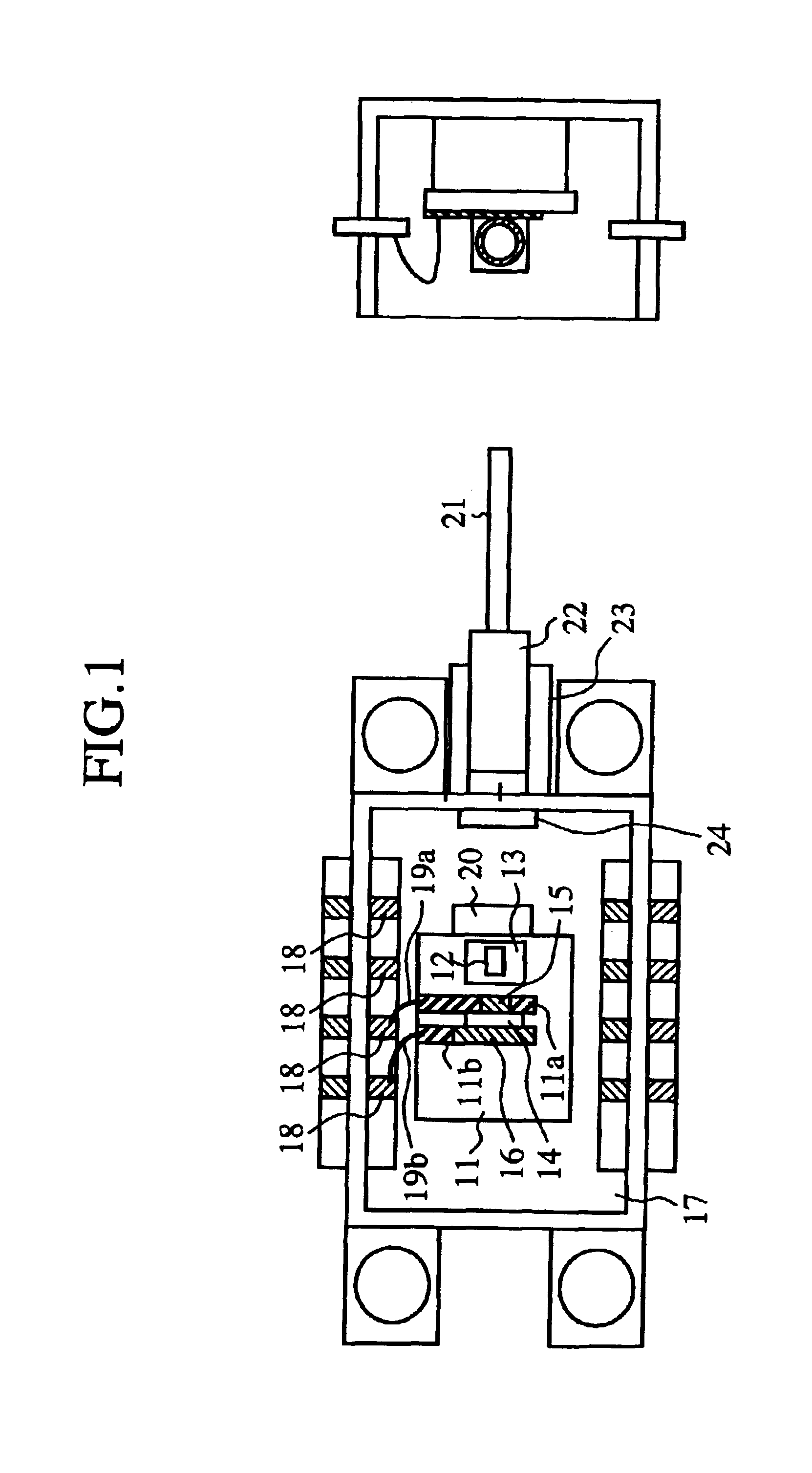

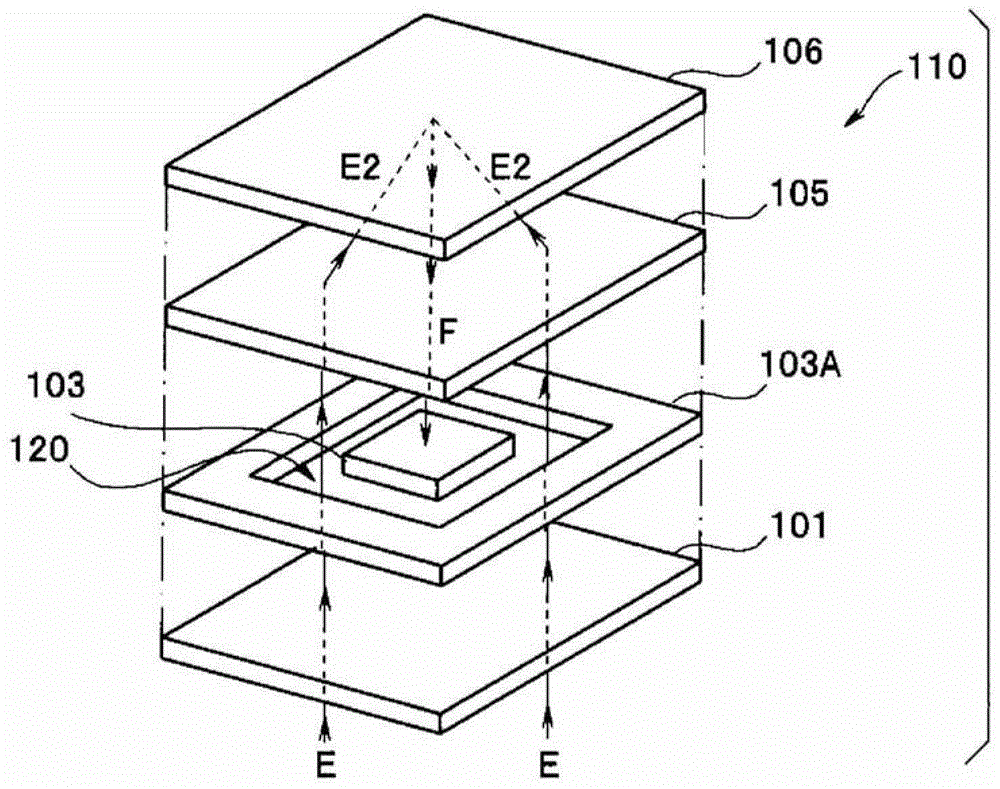

Fluorescence sensor

ActiveCN103180720AMaterial analysis by observing effect on chemical indicatorDiagnostic recording/measuringAnalyteFluorescence sensor

A fluorescence sensor (10) is provided with: a detection substrate part (20) wherein a first main surface (21) is provided with a recessed portion (23) having a bottom surface (22) that is parallel to the first main surface (21) and a PD element (13), which receives fluorescence (F) and outputs a detection signal, is formed on a lateral surface (24) of the recessed portion (23); an LED element (12) that is arranged on the bottom surface (22) of the recessed portion (23) of the detection substrate part (20) and generates excitation light (E); and an indicator layer (16) that is arranged above the LED element (12) within the recessed portion (23) and produces fluorescence (F) in accordance with the excitation light (E) and the amount of an analyte.

Owner:TERUMO KK

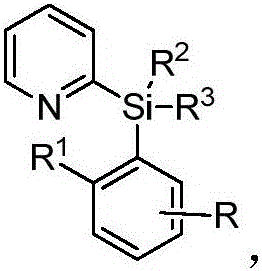

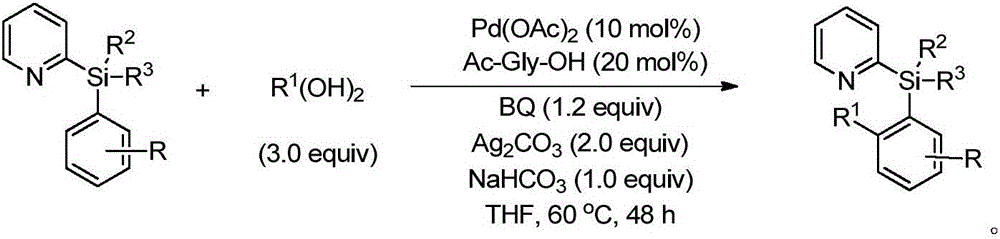

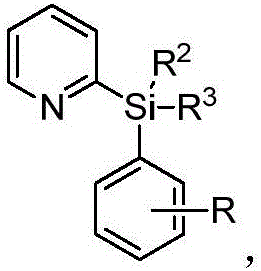

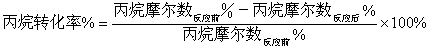

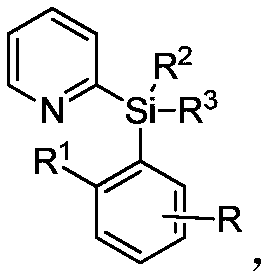

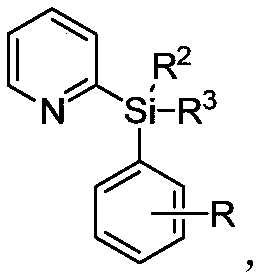

Alkyl-modified pyridylarylsilane compounds and preparation method thereof

InactiveCN105859765AMild reaction conditionsSimple and fast operationGroup 4/14 element organic compoundsSteroidsOrganic solventSynthesis methods

The invention relates to alkyl-modified pyridylarylsilane compounds and a preparation method thereof. The preparation method comprises the following step: in an organic solvent, carrying out reaction on organosilane and alkyl boric acid compounds used as raw materials by using a Pd element as a catalyst under the action of a ligand in the presence of an oxidizer and an additive for 2-48 hours while controlling the reaction temperature at 30-80 DEG C, thereby obtaining the alkyl-modified pyridylarylsilane compounds. Compared with the prior art, the synthesis method of the alkyl-functionalized pyridylarylsilane compounds is completed for the first time. The method has the advantages of mild conditions, high yield, wide substrate application range and the like, and is simple to operate.

Owner:TONGJI UNIV

Mixed C3/C4 alkane dehydrogenation catalyst and preparation method thereof

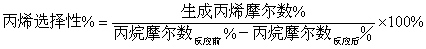

The invention relates to a mixed low-carbon alkane dehydrogenation catalyst and a preparation method thereof, which mainly solves the problem of low activity of the dehydrogenation catalyst prepared in the prior art. The present invention adopts a catalyst for mixed low-carbon alkane dehydrogenation, which comprises the following components in weight percentage: a) 0.1-10% Pt, Pd element or their oxides; b) 0.25-10% Sn , Fe, Ni elements or their oxides; c) 0.1-10% of Na, Li, K elements or their oxides; d) 0-10% of Nb, Mo, Ta, W elements or their oxides; e) The technical scheme of ZSM-5 with different Si / Al ratios of 70-99% can solve this problem well, and can be used in the industrial production of low-carbon olefins by dehydrogenation of mixed light alkanes.

Owner:CHINA PETROLEUM & CHEM CORP +1

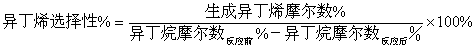

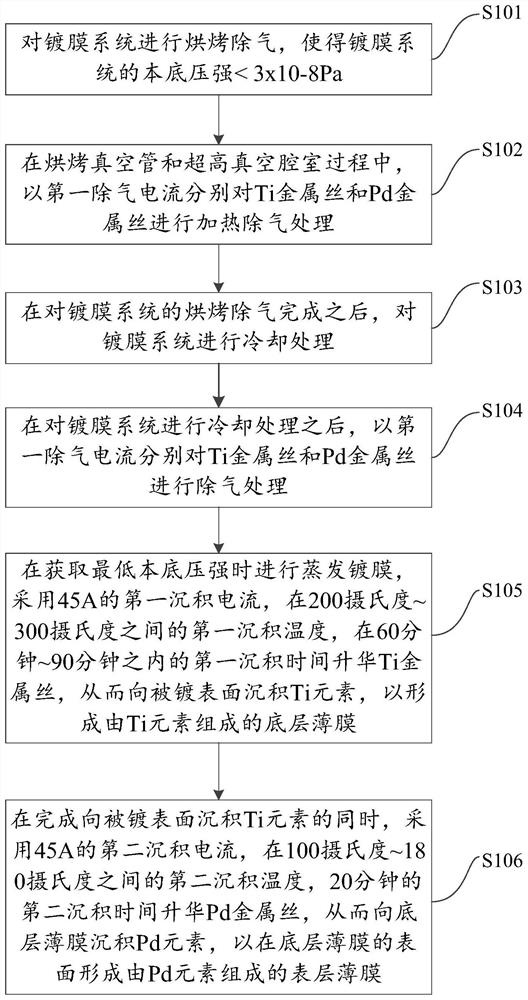

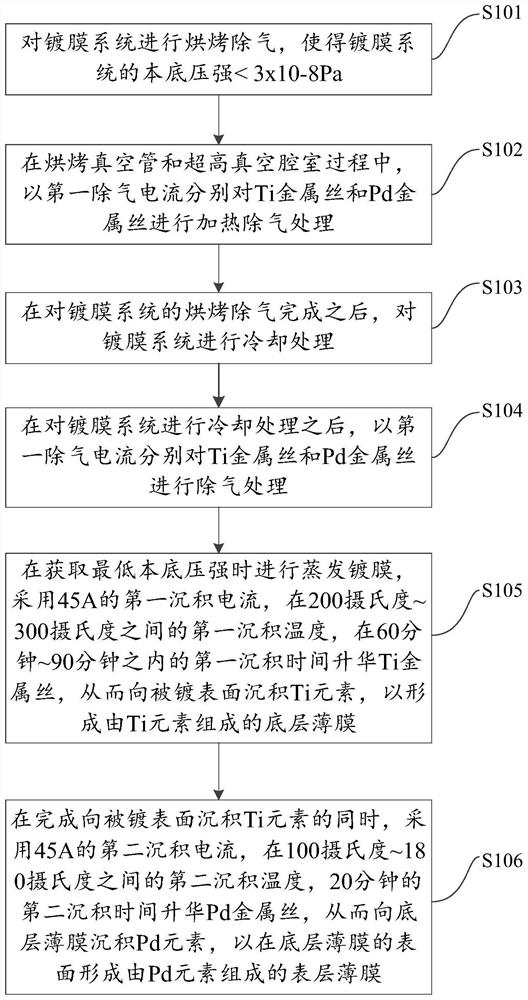

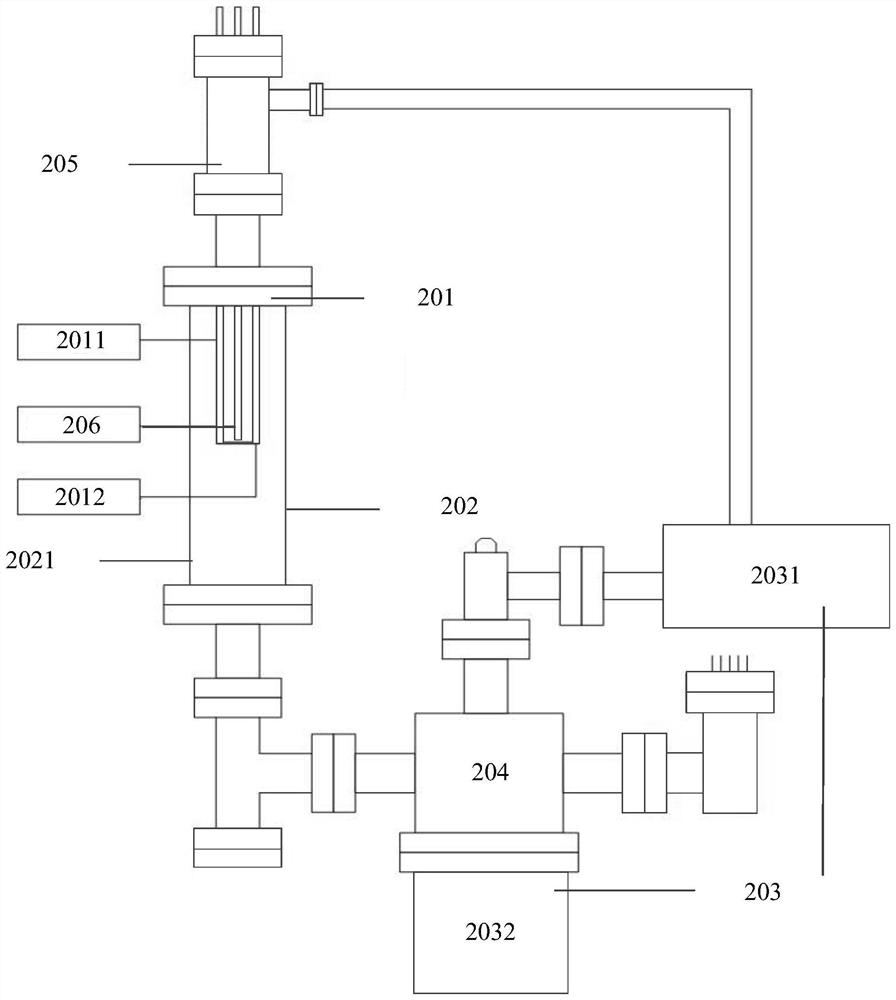

Preparation method of Pd/Ti double-layer getter film and Pd/Ti double-layer getter film

ActiveCN112342501AImprove the preparation effectAvoid destructionVacuum evaporation coatingSputtering coatingEvaporation (deposition)Deposition temperature

The invention provides a preparation method of a Pd / Ti double-layer getter film and the Pd / Ti double-layer getter film. The method comprises the steps that evaporation coating is conducted when the lowest background pressure intensity is obtained, a Ti metal wire is sublimated at a first deposition temperature ranging from 200 DEG C to 300 DEG C for a first deposition time ranging from 60 min to 90 min by adopting a first deposition current of 45 A, thereby depositing a Ti element on the plated surface to form a bottom layer film; and a Pd metal wire is sublimated at a second deposition temperature ranging from 100 DEG C to 180 DEG C for a second deposition time of 20 minutes by adopting a second deposition current of 45A while the Ti element is deposited on the plated surface, thereby depositing the Pd element on the bottom layer film and forming a surface layer film on the surface of the bottom layer film. According to the preparation method of the Pd / Ti double-layer getter film andthe Pd / Ti double-layer getter film, ultrahigh vacuum can be prevented from being damaged when the Pd / Ti double-layer getter film is prepared, so that the maintenance of the ultrahigh vacuum and the low activation temperature of the Pd / Ti double-layer getter film are both considered, the pumping speed of preparation equipment is increased in an auxiliary manner, and the preparation effect of the Pd / Ti double-layer getter film is improved.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Method for correcting fluorescent sensor, and fluorescent sensor

InactiveCN103180719AMaterial analysis by observing effect on chemical indicatorFluorescence/phosphorescenceAnalyteCorrection method

A method for correcting a fluorescent sensor in the embodiment of the present invention is provided with: a first detection signal acquiring step wherein a first detection signal is acquired at a first temperature using a fluorescent sensor (10), which is provided with an LED element (12), an indicator layer (16), and a PD element (13) that outputs a detection signal having an excitation light detection signal superimposed on a fluorescent detection signal, and which has a temperature detecting function and a temperature adjusting function; a second detection signal acquiring step wherein a second detection signal is acquired at a second temperature when an analyte quantity is equivalent to that in the first detection signal acquiring step; a correction coefficient calculating step wherein a correction coefficient for correcting the fluorescent detection signal is calculated on the basis of the first detection signal and the second detection signal; and a correcting step wherein subsequent detection signals are corrected using the correction coefficient and a temperature detection signal.

Owner:OLYMPUS CORP +1

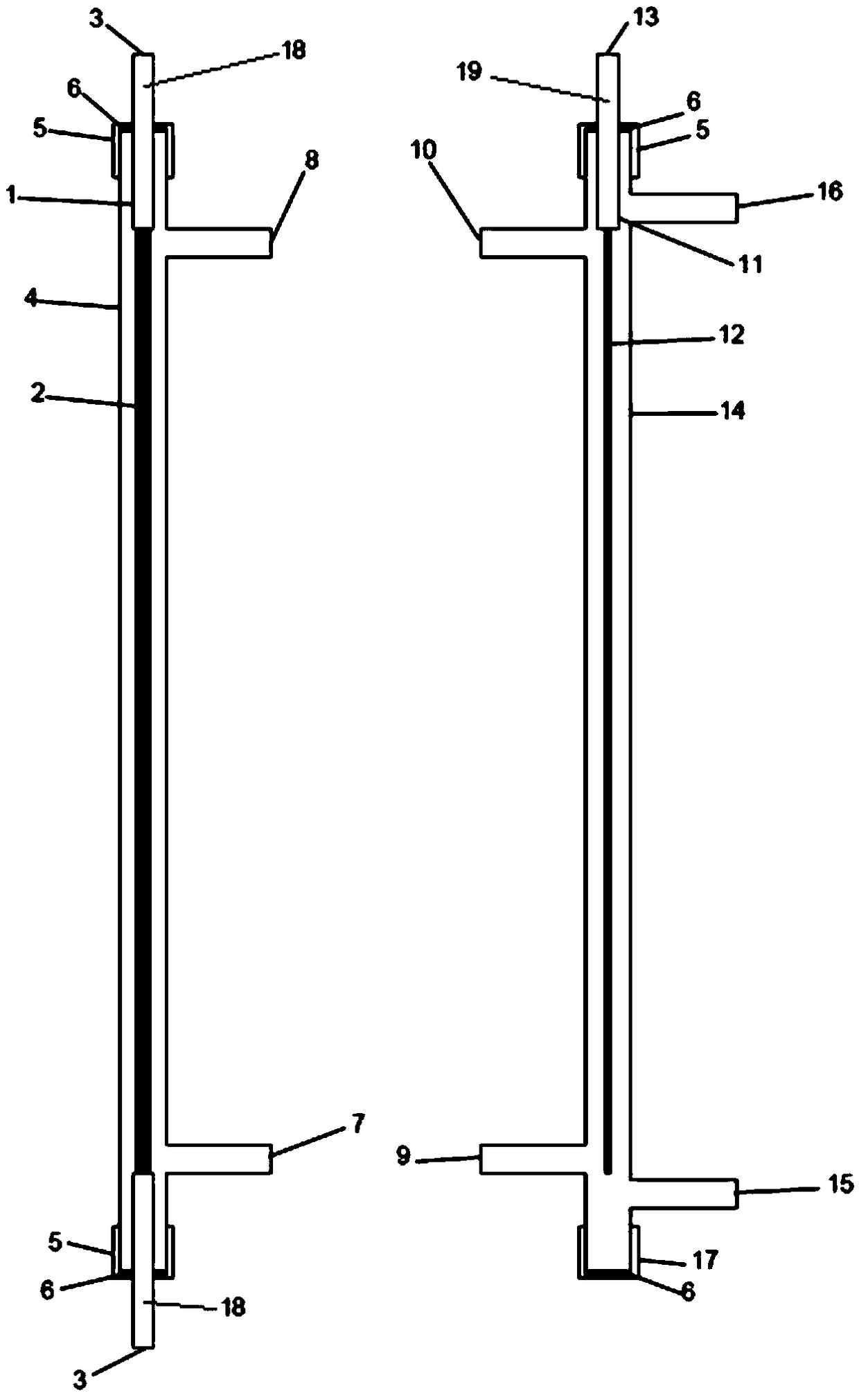

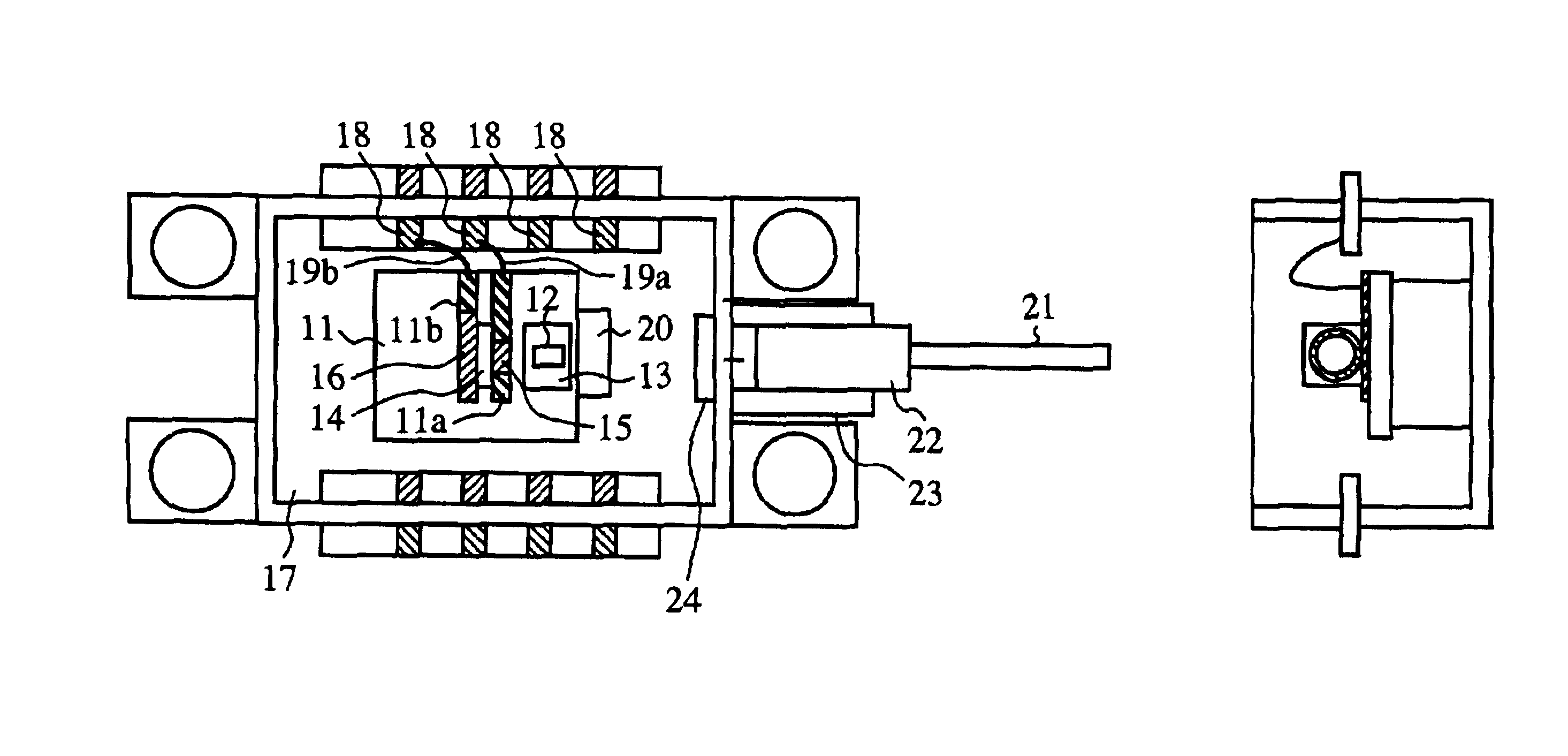

Optical module

InactiveUS7165897B2Eliminate the PD carrierSimple manufacturing processLaser detailsSolid-state devicesOptical ModuleCathode electrode

This optical module includes solder which solders an anode electrode of a PD element for detecting back light emitted from an LD element and wiring patterns, and solder which solders a cathode electrode and wiring patterns.

Owner:MITSUBISHI ELECTRIC CORP

Fluorescence sensor

ActiveCN103180720BMaterial analysis by observing effect on chemical indicatorCatheterAnalyteFluorescent light

A fluorescence sensor 10 includes a detection substrate section 20, on a first principal plane 21 of which a concave portion 23 having a bottom surface 22 parallel to the first principal plane 21 is present and, on a side surface 24 of the concave portion 23 of which a PD element 13 configured to receive fluorescent light F and output a detection signal is formed, an LED element 12 disposed on the bottom surface 22 of the concave portion 23 of the detection substrate section 20 and configured to generate excitation light E, and an indicator layer 16 disposed on an inside of the concave portion 23 on the LED element 12 and configured to generate the fluorescent light F corresponding to the excitation light E and an analyte amount.

Owner:TERUMO KK

Palladium compound being stable in acetylene atmosphere at high temperature, and application thereof

ActiveCN107803213AEasy to makeEasy to operatePreparation by halogen halide additionCatalyst activation/preparationHydrogenPalladium catalyst

The invention provides a palladium compound PdSxCl2-2x (wherein x is more than 0 and less than 1) being stable in an acetylene atmosphere at a high temperature and having a catalysis activity on acetylene hydrochlorination for synthesizing vinyl chloride. The palladium compound comprises a porous solid carrier and a PdSxCl2-2x compound supported on the surface of the porous solid carrier, the PdSxCl2-2x compound is a PdSxCl2-2x ionic compound formed through using Pd as the core and bonding S and Cl with Pd through ionic bonds, wherein x is more than 0 and less than 1, the loading quantity of the Pd element is 0.05-1% of the weight of the carrier, and the loading quantity of the S element is 0.1-5% of the weight of the carrier. The ionic bonds between Pd and S and between Pd and Cl in the PdSxCl2-2x compound formed through introducing the S element to the PdSxCl2-2x compound are stronger than ionic bonds of PdCl2 or [PdCl4]<2->, so sublimation induced loss of a complex formed by the PdSxCl2-2x compound used as an active site and C2H2 is difficult, thereby the stability of the supported palladium catalyst in an acetylene hydrochlorination reaction is improved.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of pd/ti double-layer getter film and pd/ti double-layer getter film

ActiveCN112342501BVacuum evaporation coatingSputtering coatingUltra-high vacuumActivation temperature

The application proposes a method for preparing a Pd / Ti double-layer getter film and a Pd / Ti double-layer getter film. The method includes performing evaporation coating when obtaining the lowest background pressure, and adopting a first deposition current of 45A. At the first deposition temperature between 200 degrees Celsius and 300 degrees Celsius, the Ti metal wire is sublimated within the first deposition time of 60 minutes to 90 minutes, thereby depositing Ti element on the surface to be plated to form a bottom film; While depositing the Ti element on the surface, use the second deposition current of 45A, the second deposition temperature between 100 degrees Celsius and 180 degrees Celsius, and the second deposition time of 20 minutes to sublimate the Pd metal wire, thereby depositing the Pd element on the underlying film. The surface of the base film forms the skin film. It can avoid destroying ultra-high vacuum when preparing Pd / Ti double-layer getter film, thus taking into account the maintenance of ultra-high vacuum and the low activation temperature of Pd / Ti double-layer getter film, and assisting in increasing the pumping speed of the preparation equipment , to improve the preparation effect of Pd / Ti double-layer getter films.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACAD OF SCI

A kind of preparation method of alkyl modified pyridyl aryl silane compound

InactiveCN105859765BMild reaction conditionsSimple and fast operationGroup 4/14 element organic compoundsSteroidsOrganic solventSynthesis methods

The invention relates to alkyl-modified pyridylarylsilane compounds and a preparation method thereof. The preparation method comprises the following step: in an organic solvent, carrying out reaction on organosilane and alkyl boric acid compounds used as raw materials by using a Pd element as a catalyst under the action of a ligand in the presence of an oxidizer and an additive for 2-48 hours while controlling the reaction temperature at 30-80 DEG C, thereby obtaining the alkyl-modified pyridylarylsilane compounds. Compared with the prior art, the synthesis method of the alkyl-functionalized pyridylarylsilane compounds is completed for the first time. The method has the advantages of mild conditions, high yield, wide substrate application range and the like, and is simple to operate.

Owner:TONGJI UNIV

Nano-spherical mesoporous organic metal catalyst, preparation method and application thereof

InactiveCN101773854BEasy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganometallic catalysisSilanes

The invention discloses a nano-spherical mesoporous organic metal catalyst. In the nano-spherical mesoporous organic metal catalyst, the grain diameter is between 100 and 600nm, the pore diameter is between 1.5 and 8.0nm, the pore volume is between 0.2 and 1.0cm<3> / g, the specific surface area is between 800 and 1,200m<2> / g, and the Pd element content is between 0.05 and 0.35mmol / g. The preparation method comprises the following steps: mixing organic metal silane, solution of inorganic silane, a template, water and ethanol; performing a hydrolytic polycondensation reaction by using a spray drying method; and extracting the template from an obtained solid by using alcohols to prepare the nano-spherical mesoporous organic metal catalyst. By using the method, an organic metallic catalyst with ordered mesopore arrangement can be quickly prepared, the active ingredients of the organic metallic catalyst are highly dispersed in pore passages, and the organic metallic catalyst serves as a catalyst for Barbier reaction or Sonogashira reaction in a water medium, and the organic metallic catalyst can have the catalytic performance similar to that of a homogenous organic metal catalyst.

Owner:SHANGHAI NORMAL UNIVERSITY

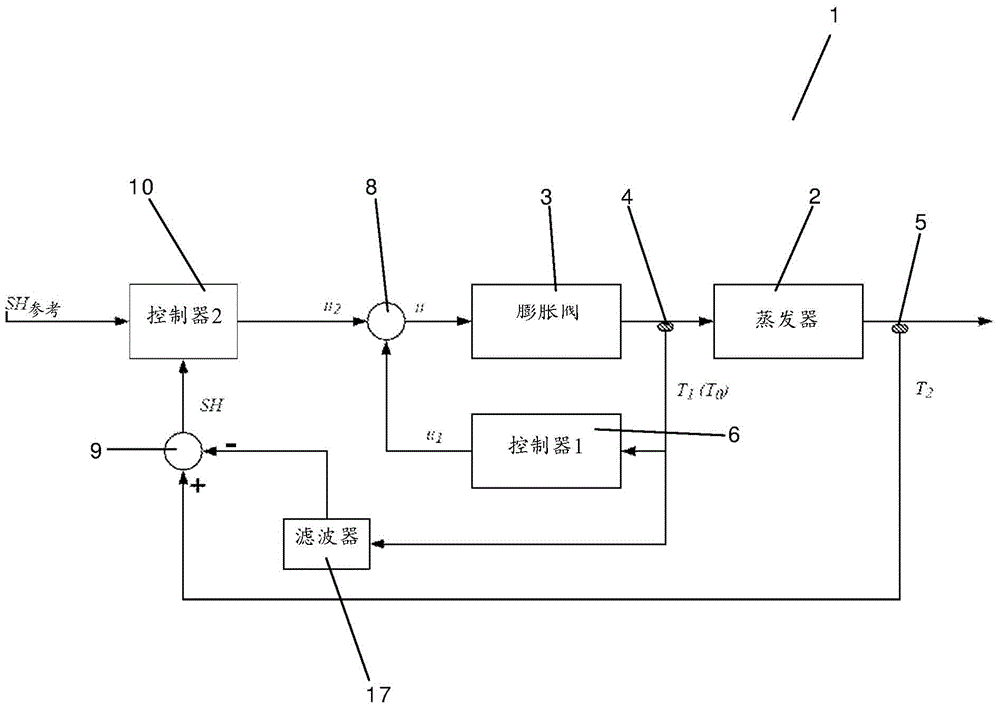

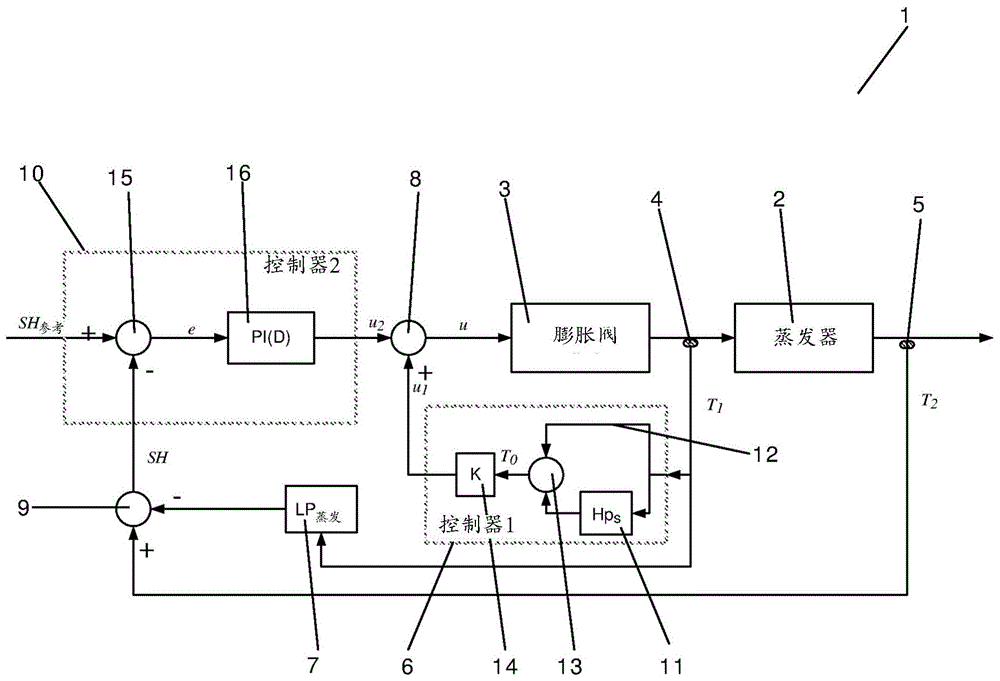

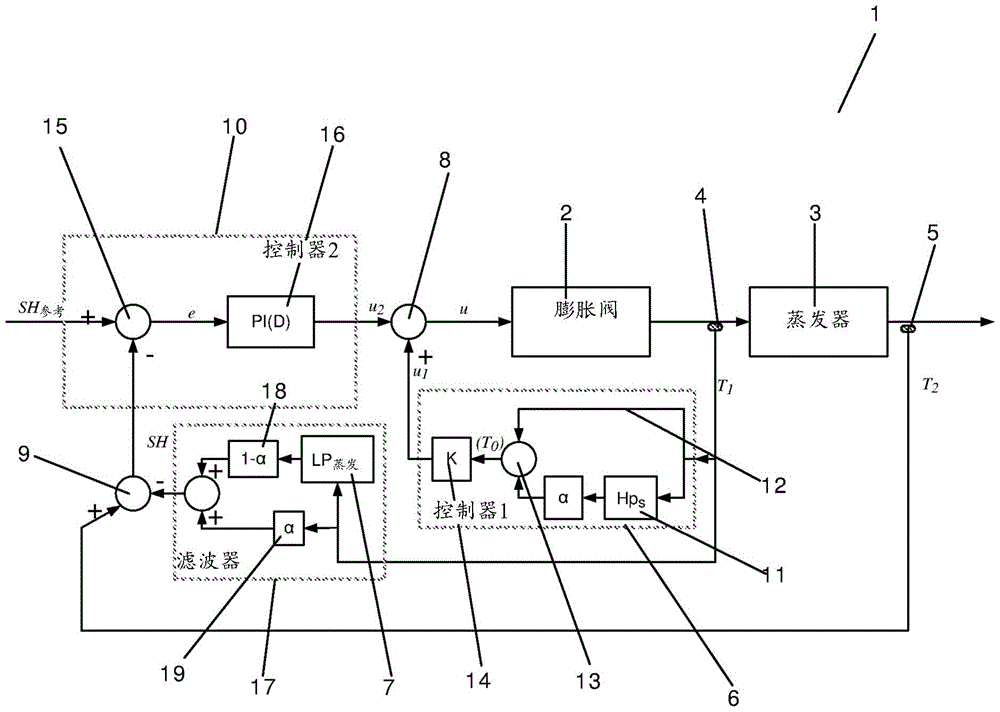

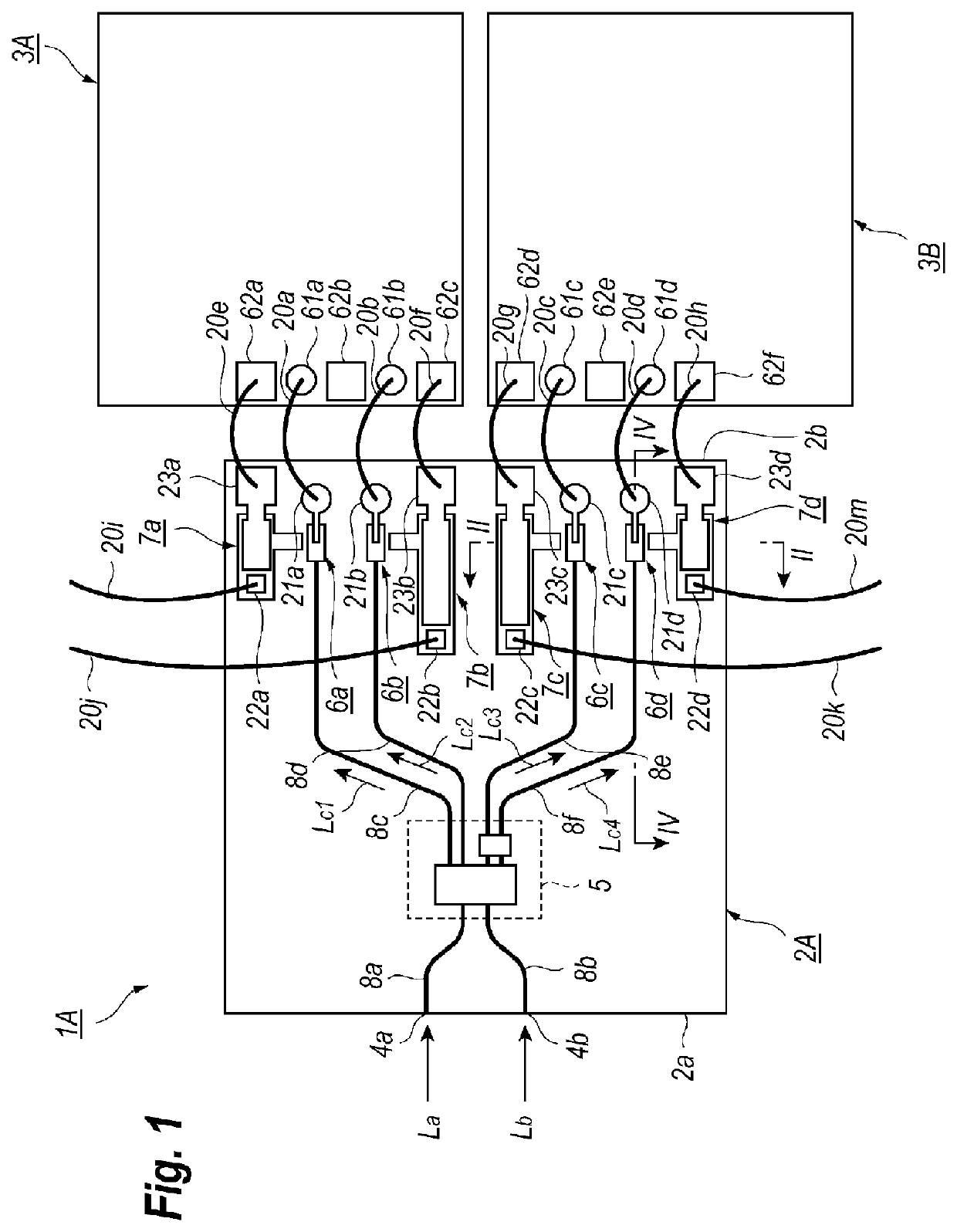

Control arrangements for controlling overheating

A control arrangement (1) for controlling superheating of a vapor compression system is disclosed herein. The control arrangement (1) comprises: a first sensor (4) and a second sensor (5) for measuring control parameters allowing to derive a superheat value; a first controller (6), the first a controller arranged to receive a signal from the first sensor (4); a second controller (10) arranged to receive a superheat value derived via a subtraction element (9) and supplying a control signal based on the derived superheat value and according to a reference superheat value; and a summation element (8) arranged to receive from the first controller (6) and the second controller (10 ) receives an input, the summing element (8) being arranged to supply a control signal for controlling the opening of the expansion device (3) based on the received input. According to a first aspect, the control arrangement comprises a low pass filter (7) arranged to receive a signal from the first sensor (4) and supply a signal to the subtraction element (9), so The low-pass filter (7) is designed according to the dynamic behavior of the evaporator (2) and / or the first sensor (4). According to a second aspect, the first controller (6) comprises a PD element.

Owner:DANFOSS AS

Corrosion-resistant titanium alloy and method for preparing same

The invention provides corrosion-resistant titanium alloy. The corrosion-resistant titanium alloy comprises, by weight, 0.04-0.25% of Pd, higher than 0% and lower than or equal to 50% of Zr and the balance Ti. The corrosion-resistant titanium alloy has the advantages that the contents of various elements are strictly controlled, effects of improving the crevice corrosion resistance of the corrosion-resistant titanium alloy mainly can be realized by the Pd elements in the corrosion-resistant titanium alloy, and anti-pollution effects of the hydrogen absorption ability of the surfaces of the corrosion-resistant titanium alloy can be improved; the Zr elements are added on the basis of the Pd elements, the Zr used as passive metal is negative in initiating passive potential as compared with the Ti and is high in passivation ability, accordingly, passive films can be easily generated on the surfaces of the corrosion-resistant titanium alloy, and the corrosion resistance of the corrosion-resistant titanium alloy in diversified corrosive media can be enhanced; as shown by experimental results, the enhancement amplitude of the corrosion resistance of the corrosion-resistant titanium alloyin sodium chloride solution can reach 11.28-66.29% as compared with comparison alloy (Ti-0.04Pd) obtained by the aid of identical treatment processes.

Owner:中鼎特金秦皇岛科技股份有限公司 +1

Method for synthetizing N,N-diisopropylethylamine

InactiveCN101585776BSimple processHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyMoisture

The invention relates to a method for synthetizing N,N-diisopropylethylamine; the method comprises the steps as follows: taking diisopropylamine, epoxy ethane as the raw material, taking zinc chloride, tetramethyl ammonium hydroxide as the catalyst, taking the water as the circulating medium, reacting and aging; the reaction is carried out under gas and liquid phases utilizing single kettle production; the specific operating conditions being normal pressure, the temperature being 50 to 180 degrees centigrade, the air speed of ethylene oxide gas being 50 to 100 kg / h, the mol ratio between diisopropylamine and epoxy ethane being 1-1.5, the dosage of the catalyst being 0.5-1 weight of diisopropylamine; thermal reacting for two hours, then discharging and filtering to remove the solid catalyst, evaporating diisopropylamine and moisture under normal pressure, adding with activated carbon dipping with Ru, Pt or Pd elements, decompressing, rectifying, collecting the products. The invention has the advantages of taking the water solution of the diisopropylamine as the main reaction line, adding with little catalyst into the water solution of the diisopropylamine, and reacting through the epoxy ethane under normal pressure, having excellent reaction effect.

Owner:HANGZHOU XINDE ENVIRONMENTAL PROTECTION TECH

Preparation method of difunctional biphenyl compound modified by alkyl and alkenyl

InactiveCN105837388BPharmaceutically activeLow yieldCarboxylic acid nitrile preparationOrganic compound preparationOrganic solventSynthesis methods

The invention relates to alkyl / alkenyl-modified difunctional biphenyl compounds and a preparation method thereof. The preparation method comprises the following step: by controlling the reaction temperature at 50-110 DEG C in an organic solvent, carrying out reaction on 2-iodobiphenyl, chloralkane and olefin by using the Pd element as a catalyst for 2-24 hours in the presence of an alkali, a reducer and additives, thereby obtaining the alkyl / alkenyl-modified difunctional biphenyl compounds. Compared with the prior art, the synthesis method of the alkyl / alkenyl-modified difunctional biphenyl compounds is completed for the first time. The method has the advantages of mild conditions, high yield, wide substrate application range and the like, and is simple to operate.

Owner:TONGJI UNIV

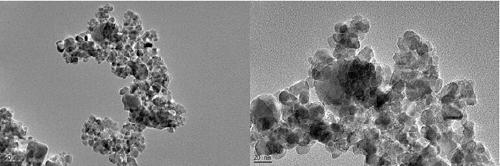

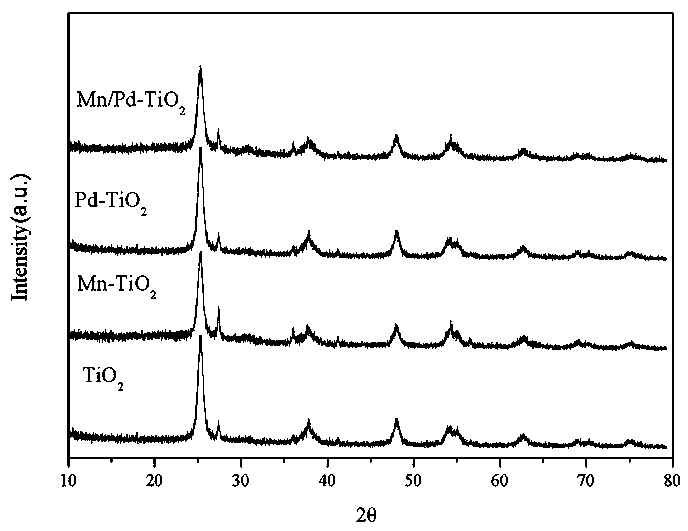

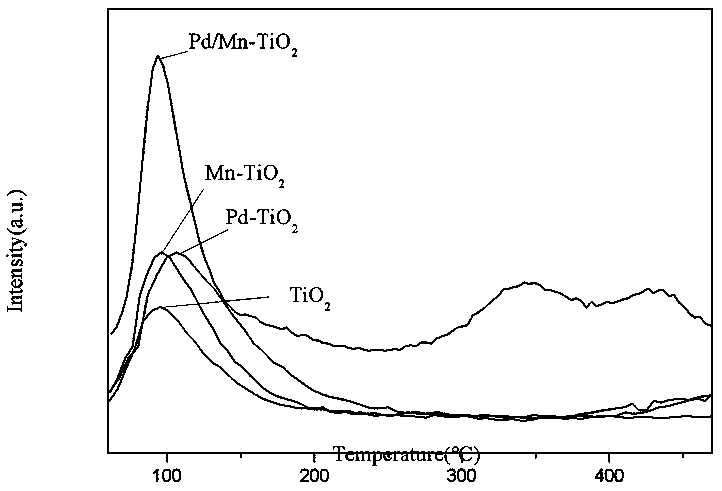

Preparation method and application of Mn and Pd doped TiO2 catalyst

ActiveCN109621954AHigh selectivityReduce energy consumptionHydrocarbon from carbon oxidesOrganic compound preparationEnergy consumptionMn element

The invention discloses a preparation method and application of an Mn and Pd doped TiO2 catalyst. The catalyst comprises TiO2 with optical excitation activity and Mn and Pd elements doped in the TiO2,and the content of the Mn element in the catalyst is 0.2-2wt% and the content of the Pd element in the catalyst is 0.2-2wt% according to the 100 mass percentages of TiO2. The preparation method includes the following steps that oxidized Mn and Pd doped TiO2 is prepared through a sol-gel method; H2 is used for reducing oxidized Mn and Pd into low-order state or simple-substance Mn and Pd; comparedwith CO, CH4 and other products which are generated through a catalytic reaction of most other similar catalysts, in the scheme, a photothermal coupling effect is used for improving the performance when catalytic reduction of CO2 is conducted, a product C2H5OH has higher performance of multiple purposes and transportation and storage convenience, and the application value of the reaction productis increased; in addition, in the scheme, energy consumption is low, and the selectivity for a C2 product is high.

Owner:FUZHOU UNIV

Photodiode device monolithically integrating waveguide element with photodiode element type of optical waveguide

A photodiode (PD) device that monolithically integrates a PD element with a waveguide element is disclosed. The PD device includes a conducting layer with a first region and a second region next to the first region, where the PD element exists in the first region, while, the waveguide element exists in the second region and optically couples with the PD element. The waveguide element includes a core layer and a cladding layer on the conducting layer, which forms an optical confinement structure. The PD element includes an absorption layer on the conducting layer and a p-type cladding layer on the absorption layer, which form another optical confinement structure. The absorption layer has a length at least 12 μm measured from the interface against the core layer.

Owner:SUMITOMO ELECTRIC DEVICE INNOVATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com