Preparation method and application of Mn and Pd doped TiO2 catalyst

A catalyst, CO2 technology, used in catalysts, carbon compound catalysts, chemical instruments and methods, etc., can solve the problems of inability to effectively induce reduction and oxidation reactions, low application value, low utilization of light energy, etc., to achieve strong multi-purpose performance, convenience of transportation and storage, improved application value, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) At room temperature and pressure, add 3.133 mL of deionized water and 1 mL of 12 mol L to 40 mL of ethanol. -1 of concentrated hydrochloric acid, 0.0347g of MnCl 2 ·4H 2 O and 0.867mL 6mg·mL -1 PdCl 2 Then, 12 mL of tetrabutyl titanate was added dropwise to the vigorously stirred solution until a gel was formed. The obtained gel was dried in an oven at 80 °C for 12 h, and aged at room temperature for 24 h to obtain the oxidized state. Mn, Pd doped TiO 2 .

[0030] 2) The obtained oxidation state Mn and Pd doped TiO 2 Placed in a quartz reactor, passed hydrogen, and reacted at 350 ° C for 2 h. That is to obtain low-valence and elemental Mn, Pd-doped TiO 2 catalyst.

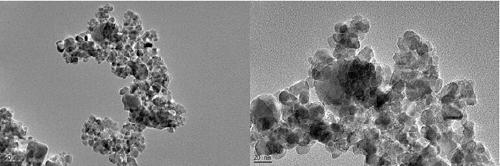

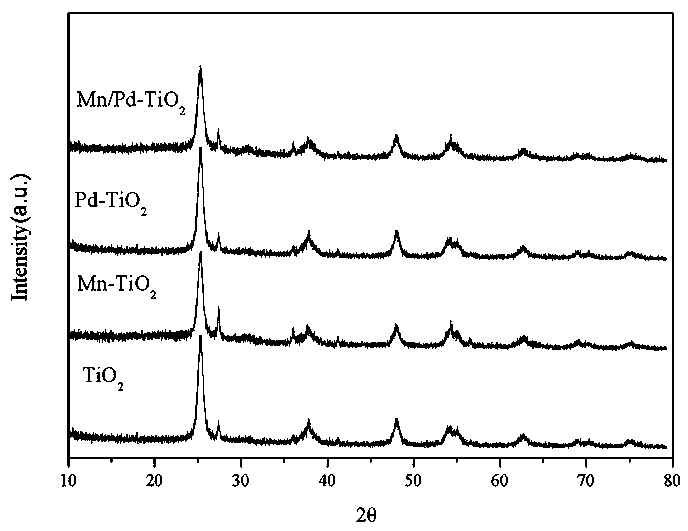

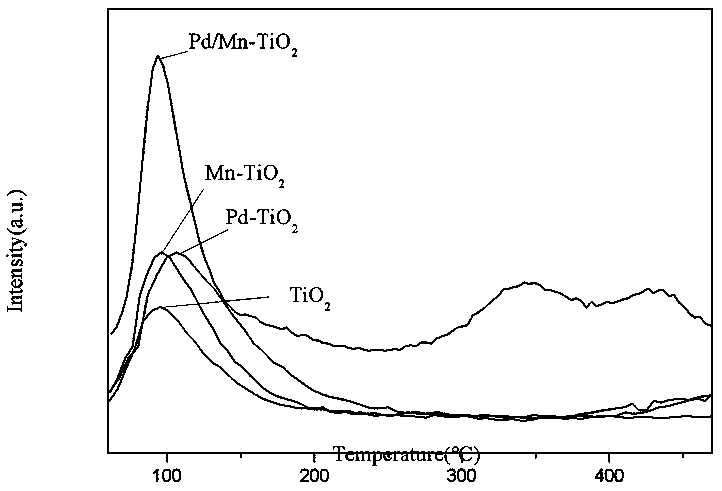

[0031] figure 1 is the obtained Mn / Pd-TiO 2 Transmission electron microscope image of the catalyst. from figure 1 It can be seen that Mn / Pd-TiO 2 The catalyst exhibits a nano-block-packed morphology, and this result may be helpful for the adsorption of reactants, for CO 2 activation has a cert...

Embodiment 2

[0044] Mn-TiO 2 The preparation of catalyst, the concrete steps are:

[0045] 1) At room temperature and pressure, add 4 mL of deionized water and 1 mL of 12 mol L to 40 mL of ethanol. -1 of concentrated hydrochloric acid, 0.0347g of MnCl 2 ·4H 2 O; then, 12 mL of tetrabutyl titanate was added dropwise to the vigorously stirred solution until a gel was formed, and the resulting gel was dried in an oven at 80 °C for 12 h, and aged at room temperature for 24 h to obtain the oxidized state. Mn-doped TiO 2 .

[0046] 2) The obtained oxidation state Mn-doped TiO 2 Placed in a quartz reactor, passed hydrogen, and reacted at 350 ° C for 2 h. That is, low-valence Mn-doped TiO 2 catalyst.

Embodiment 3

[0048] Pd-TiO 2 The preparation of catalyst, the concrete steps are:

[0049] 1) At room temperature and pressure, add 3.133 mL of deionized water and 1 mL of 12 mol L to 40 mL of ethanol. -1 of concentrated hydrochloric acid and 0.867mL of 6mg·mL -1 PdCl 2 Then, 12 mL of tetrabutyl titanate was added dropwise to the vigorously stirred solution until it formed a gel, and the obtained gel was dried in an oven at 80 °C for 12 h, aged at room temperature for 24 h, and the oxidized state was obtained. Pd-doped TiO 2 .

[0050] 2) The obtained oxidation state Pd-doped TiO 2 Placed in a quartz reactor, passed hydrogen, and reacted at 350 ° C for 2 h. That is to obtain low-valence and elemental Pd-doped TiO 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com