Gas-phase synthesis method for small-scale high-dispersion Pd/C catalyst

A gas-phase synthesis and catalyst technology, applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve problems such as uneven distribution of catalytic species, difficult synthesis process, wide metal particle size distribution, etc., to avoid synthesis The process is not easy to control, the effect of reducing production steps, saving production time and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a kind of gas phase synthesis method of small-scale, highly dispersed Pd / C catalyst, and the concrete steps of this method are:

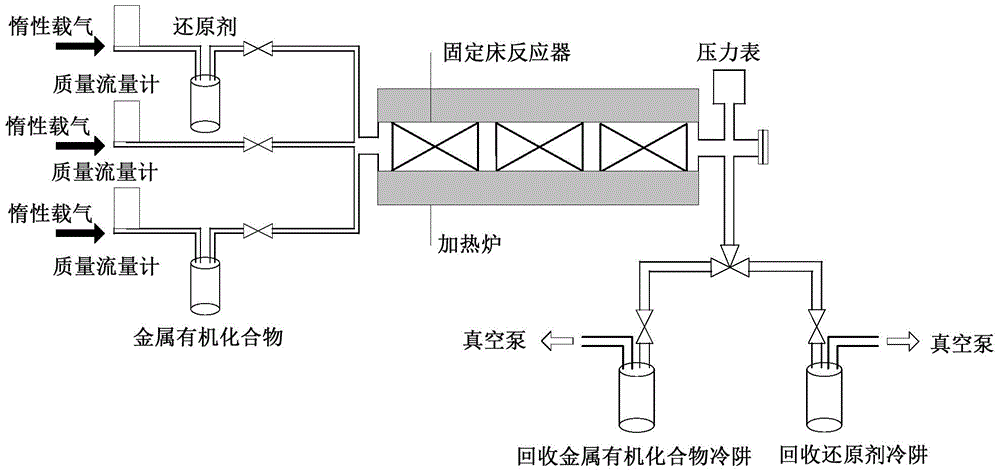

[0024] Step 1: Place 1 g of activated carbon carrier in a fixed-bed reactor, seal the reactor, feed nitrogen gas and adjust the reactor pressure to 130 Pa, heat the activated carbon to 200°C, and heat palladium hexafluoroacetylacetonate to 60°C;

[0025] Step 2, palladium hexafluoroacetylacetonate steam enters the reactor and reacts with the surface groups of the activated carbon to undergo a gas-solid interface reaction. The time of the gas-solid interface reaction is 2 minutes. The Pd element is fixed on the surface of the activated carbon, and then a reducing gas is introduced into the reactor Formaldehyde reduces the Pd element fixed on the surface, and the reduction reaction time is 2 minutes. The above process is cycled once to generate 0.5% Pd / C catalyst.

[0026] Take by weighing 218.1 mg of the catalyst prep...

Embodiment 2

[0028] This embodiment provides a kind of gas phase synthesis method of small-scale, highly dispersed Pd / C catalyst, and the concrete steps of this method are:

[0029] Step 1: Place 1 g of activated carbon carrier in a fixed-bed reactor, seal the reactor, feed nitrogen gas and adjust the reactor pressure to 130 Pa, heat the activated carbon to 200°C, and heat palladium hexafluoroacetylacetonate to 60°C;

[0030] Step 2, palladium hexafluoroacetylacetonate steam enters the reactor and reacts with the surface groups of the activated carbon to undergo a gas-solid interface reaction. The time of the gas-solid interface reaction is 5 minutes. The Pd element is fixed on the surface of the activated carbon, and then the reducing gas is introduced into the reactor Formaldehyde reduces the Pd element fixed on the surface, and the reduction reaction time is 5 minutes. The above process is cycled once to generate 1.4% Pd / C catalyst.

[0031] Weigh 77.9 mg of the catalyst prepared in Ex...

Embodiment 3

[0033] This embodiment provides a kind of gas phase synthesis method of small-scale, highly dispersed Pd / C catalyst, and the concrete steps of this method are:

[0034] Step 1: Place 1 g of activated carbon carrier in a fixed-bed reactor, seal the reactor, feed nitrogen gas and adjust the reactor pressure to 130 Pa, heat the activated carbon to 200°C, and heat palladium hexafluoroacetylacetonate to 60°C;

[0035] Step 2: Palladium hexafluoroacetylacetonate vapor enters the reactor to react with the surface groups of the activated carbon to undergo a gas-solid interface reaction. The time for the gas-solid interface reaction is 20 minutes. The Pd element is fixed on the surface of the activated carbon, and then a reducing gas is introduced into the reactor Formaldehyde reduces the Pd element fixed on the surface, and the reduction reaction time is 20 minutes. The above process is cycled once to generate a 5.0% Pd / C catalyst.

[0036] When the gas-solid interface reaction time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com