Method for preparing ordered magnetic nanoparticle composite film with super-high density

A technology of magnetic nanoparticles and composite thin films, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of particle agglomeration self-assembled ordered array, insufficient magnetic coercivity at room temperature, and unable to meet practical requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

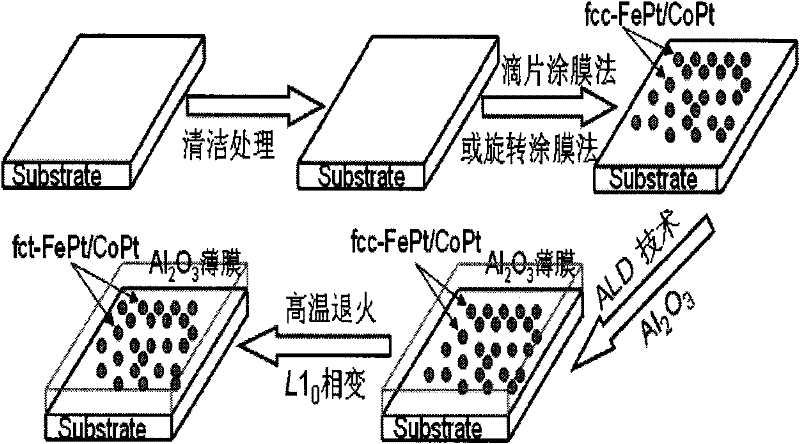

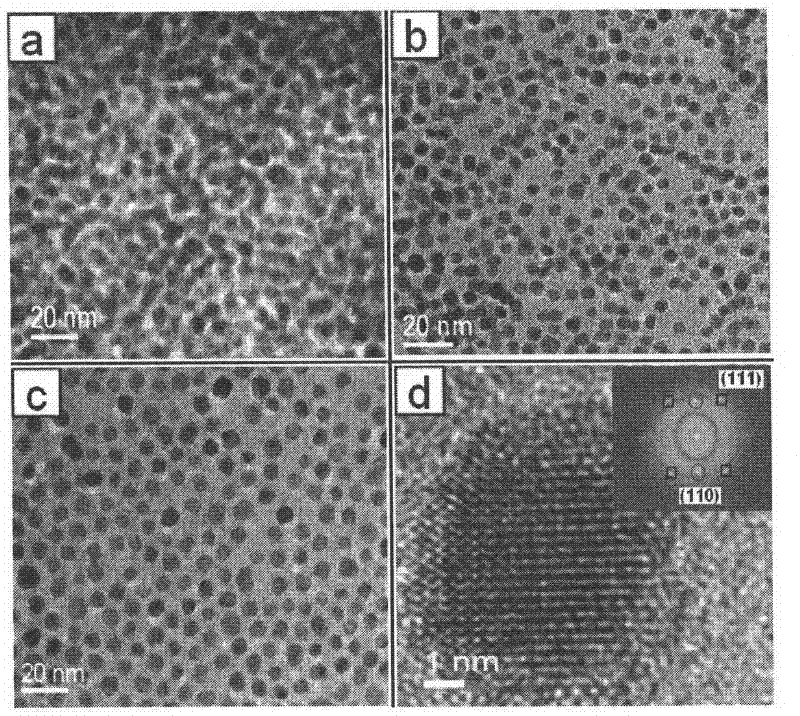

[0025] 1) Preparation of superparamagnetic single-layer FePt nanoparticle lattice: the pre-prepared 4.5nm iron-platinum particles are dispersed in a mixed solution with a volume ratio of 1:2 in hexane: octane, and the mixed solution at this time contains FePt is 3 mg / mL. Firstly, a 1.0×1.0 cm2 Si wafer was cleaned by a standard RCA method, and then treated with HF (water at a volume ratio of 1:10) for 30 seconds to remove oxides on the surface of the silicon wafer. At room temperature, the self-assembled FePt ordered particle lattice was formed by the droplet method, and finally baked at 80° C. for 30 minutes.

[0026] 2) Growth of Al by atomic layer deposition technology 2 o 3 Protective film: Put the Si substrate with FePt particles dispersed on the surface into the ALD reaction chamber, and then deposit a layer of 10nm Al on its surface 2 o 3 thin film, superparamagnetic FePt / Al 2 o 3 Composite film. The set ALD deposition parameters are:

[0027] Reaction chamber t...

Embodiment 2

[0032] 1) Preparation of superparamagnetic single-layer FePt nanoparticle lattice: disperse the 4nm iron-platinum particles prepared in advance in a mixed solution with a volume ratio of 1:1.5 in hexane: octane, and the mixed solution containing FePt at this time is 5mg / mL. A 1.0 × 1.0 cm2 SiO 2 The slices were cleaned. The self-assembled FePt ordered particle lattice is formed by spin film spin coating method, and the silicon wafer needs to be kept at 80°C for 30 minutes to ensure that the solvent is completely volatilized.

[0033] 2) Growth of Al by atomic layer deposition technology 2 o 3 Protective film: Put the Si substrate with FePt particles dispersed on the surface into the ALD reaction chamber, and then deposit a layer of 20 nanometer Al on its surface 2 o 3 thin film, superparamagnetic FePt / Al 2 o 3 Composite film. The set ALD deposition parameters are:

[0034] Reaction chamber temperature: room temperature;

[0035] Reaction source: deposited Al 2 o 3 ...

Embodiment 3

[0039] 1) Preparation of superparamagnetic single-layer FePt nanoparticle lattice: 4nm iron-platinum particles prepared in advance are dispersed in a mixed solution with a volume ratio of 1:3 in hexane: octane, and the mixed solution containing FePt at this time is 3mg / mL. First, the surface of 1.0×0.5 cm2 MgO is purged clean, and then the MgO substrate is annealed at 700° C. for 30 minutes. Then spin-coating method is used to form a self-assembled FePt ordered particle lattice, and the silicon wafer needs to be kept at 70°C for 40 minutes to ensure that the solvent is completely volatilized.

[0040] 2) Growth of Al by atomic layer deposition technology 2 o 3 Protective film: Put the Si substrate with FePt particles dispersed on the surface into the ALD reaction chamber, and then deposit a layer of 30nm Al on its surface 2 o 3 thin film, superparamagnetic FePt / Al 2 o 3 Composite film. The set ALD deposition parameters are:

[0041] Reaction chamber temperature: 450°C;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com