Method for synthetizing N,N-diisopropylethylamine

A technology of propylethanolamine and diisopropylamine, which is applied in the field of N, can solve the problems of high reaction temperature, complicated process operation, and increased reaction cost, and achieve the effect of high yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the synthetic method of this diisopropyl ethyl (alcohol) amine

[0017] (1) Using diisopropylamine and ethylene oxide as raw materials, zinc chloride and tetramethylammonium hydroxide as catalysts, and water as a circulating medium for reaction aging.

[0018] (2), the reaction is carried out in two phases of gas and liquid, and it is produced in a single kettle. The specific operating conditions are pressure: normal pressure, temperature: 50-180 ° C, ethylene oxide gas space velocity: 50-100kg / h, diisopropylamine: ethylene oxide molar ratio is 1-1.5, catalyst dosage: 0.5-1 weight of diisopropylamine.

[0019] (3) Diisopropylamine is weighed into the reaction kettle, and then put into the prepared catalyst. After fully mixing, the mixing temperature is controlled to be normal temperature, and ethylene oxide is introduced at normal temperature and pressure according to the specified flow rate, and the heat preservation reaction is completed. After two hou...

Embodiment 2

[0020] Embodiment 2: make according to the method described in embodiment 1

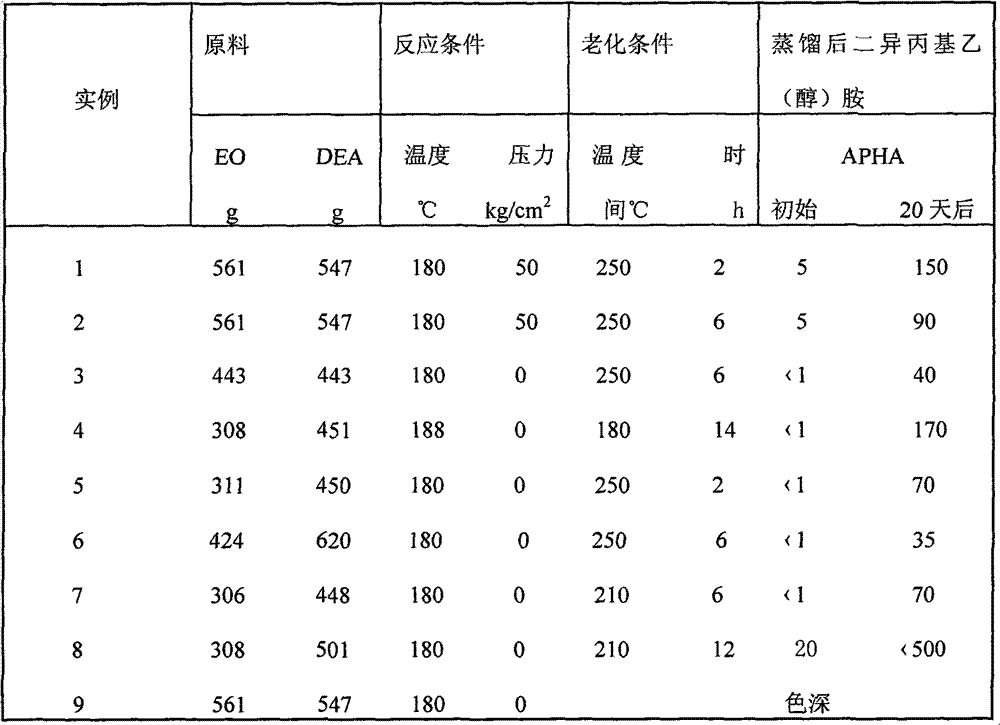

[0021] Table 1 Diisopropylamine and ethylene oxide reaction and aging conditions

[0022]

[0023] Note: EO is ethylene oxide, DEA is diisopropylamine, APHA is the color standard unit

[0024] It can be known from Table 1 that the reaction temperature of ethylene oxide and diisopropylamine is 180°C. After the reaction, it can be aged at 210-250°C for 6-12 hours. From example 6 and example 7 of table 1, it can be seen that after the reaction, without aging treatment, although it can also be separated by distillation, the resulting product is except that the color is dark, and the standing time is also short.

Embodiment 3

[0025] Embodiment 3: make according to the method described in embodiment 1

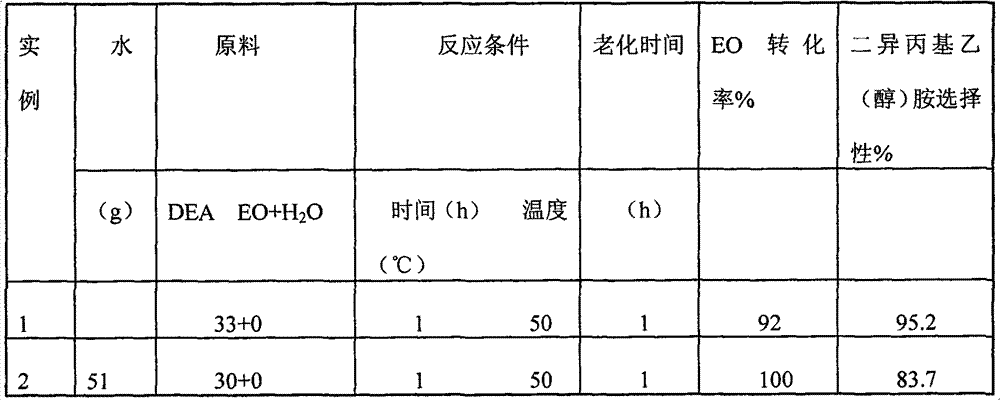

[0026] Table 2 water is used as the process condition and reaction result of circulating solution

[0027]

[0028] As can be seen from Table 2, water can obtain the high conversion rate of material oxyethane and the high selectivity of diisopropyl ethyl (alcohol) amine as circulating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com