Hydrogen substrate biological Pd reactor performing aeration with no-pore hollow fiber membrane

A fiber membrane and reactor technology, applied in the field of hydrogen-based bio-palladium reactors, can solve problems such as inability to withstand impact loads, inability to restore, and limited number of membrane filaments, and achieve good air tightness, good fixation, and protection against palladium The effect of the loss of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

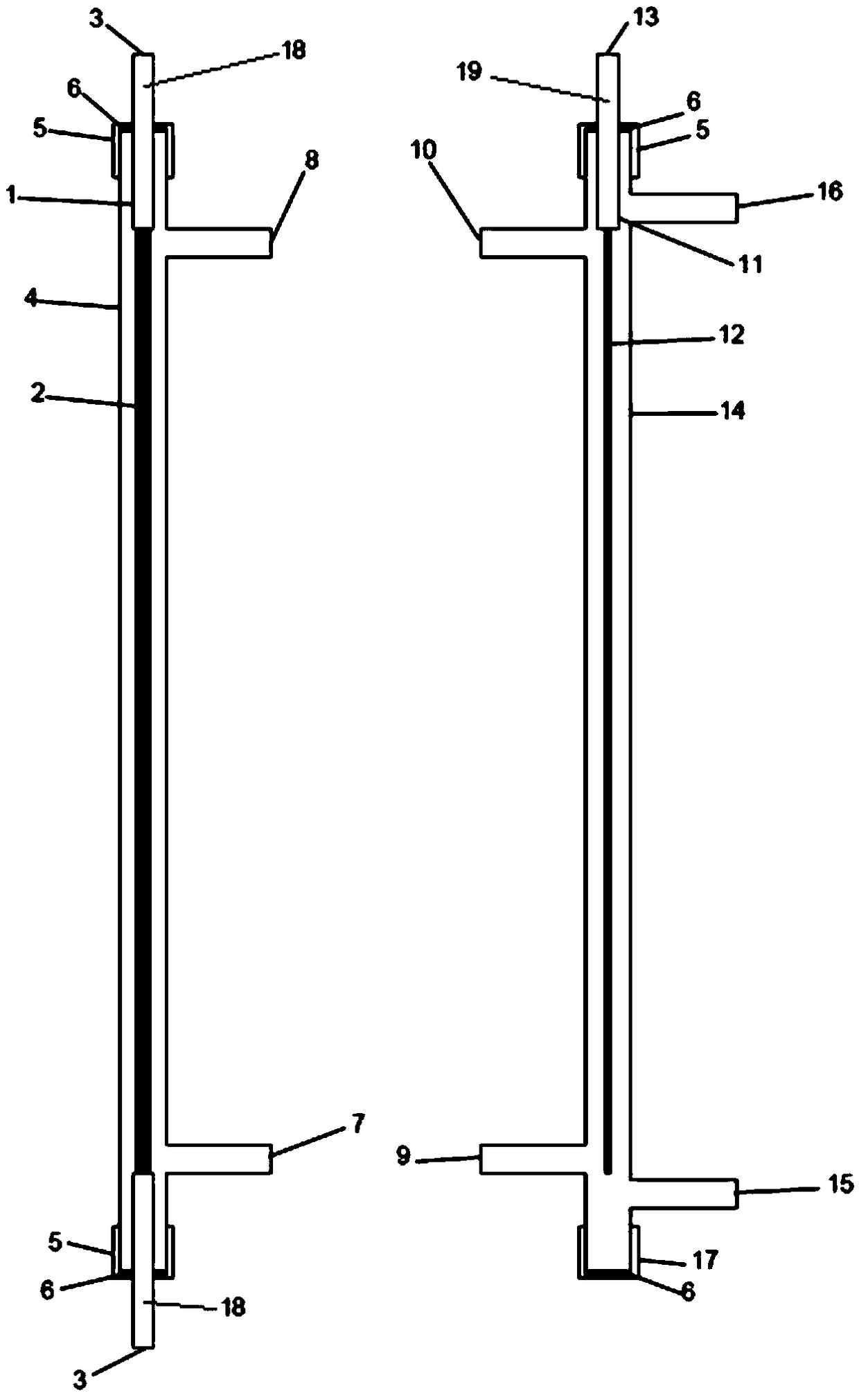

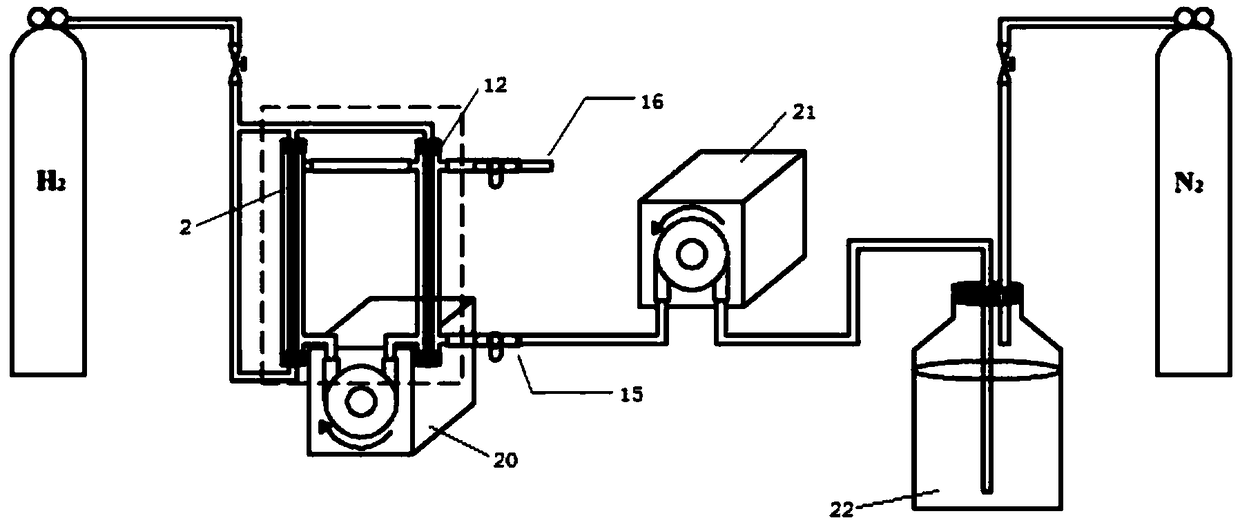

[0048] A hydrogen matrix biopalladium reactor aerated with non-porous hollow fiber membranes, such as figure 1 As shown, the reactor includes:

[0049] Main reactor: comprising the main reactor body 4, the first non-porous hollow fiber membrane module 1 attached with bio-palladium inside the main reactor body 4, and the two ends of the first non-porous hollow fiber membrane module 1 The first hydrogen gas inlet 3, the main reactor pipe body 4 upper end side is provided with the main reactor reflux water outlet 8, the main reactor pipe body 4 lower end side is provided with the main reactor reflux water inlet 7, the first non-porous The hollow fiber membrane module 1 includes a first non-porous hollow fiber membrane filament 2 vertically arranged along the main reactor body 4;

[0050] Secondary reactor: including secondary reactor body 14, the second non-porous hollow fiber membrane module 11 attached with bio-palladium inside the secondary reactor body 14, and the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com