Pd-loaded Ti/CeO2 nano compound type catalyst as well as preparation method and application thereof

A composite, catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of limited cerium cations and oxygen holes, low catalytic activity, The problem of high industrial cost, to achieve the effect of easy industrial production, high catalytic performance, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

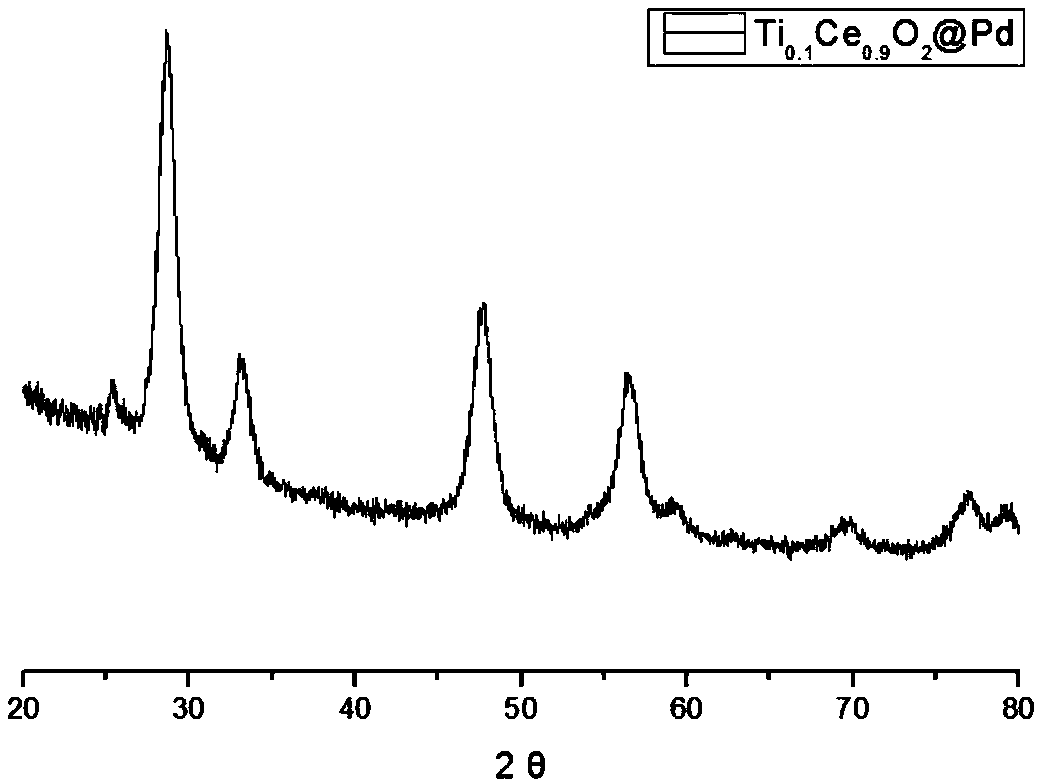

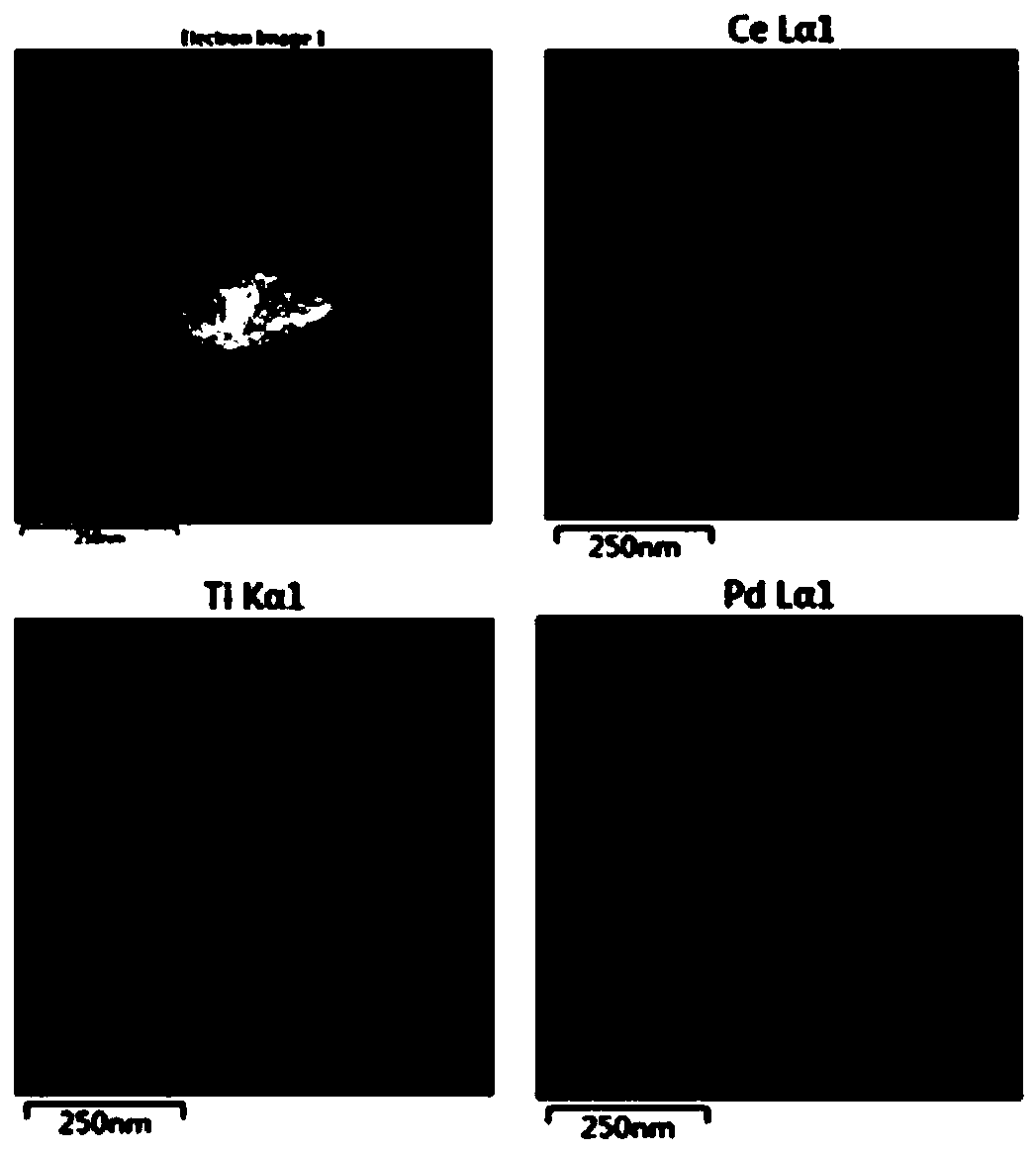

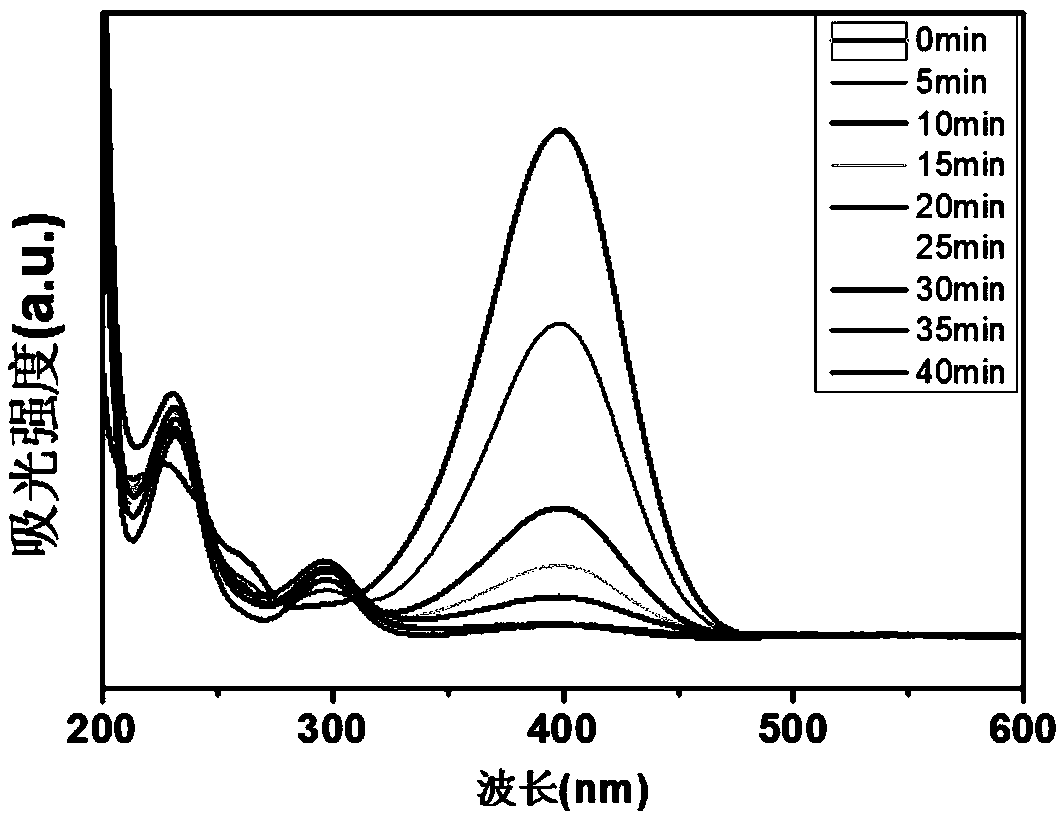

[0039] 1) Pd loaded Ti / CeO 2 Preparation of nanocomposite catalysts:

[0040]Dissolve 0.3907 g of cerium nitrate hexahydrate in 20 mL of a mixed solvent of ethanol and water (ethanol: water = 7:1), add 34 uL of tetrabutyl titanate, stir at room temperature for 20 min, then add the ethanol solution of pyromellitic acid (0.254g of pyromellitic acid dissolved in 20mL of ethanol), the above mixture was heated in an 80°C oil bath for 1h, quenched by adding water, and dried by centrifugation to obtain a white precipitate with a yield of 78%.

[0041] Put the obtained white precipitate in a muffle furnace and sinter at 500°C for 3h to obtain Ti / CeO 2 oxide. Dissolve 60mg of polyvinylpyrrolidone in 80mL of glycerol, add 100mg of Ti / CeO 2 Oxides, placed in an oil bath at 120°C, added an aqueous solution of potassium tetrachloropalladate (8mg potassium tetrachloropalladate dissolved in 1.2mL water), stirred at constant temperature for 2h, and then dried by high-speed centrifugation. ...

Embodiment 2

[0049] 1) Pd loaded Ti / CeO 2 Preparation of nanocomposite catalysts:

[0050] Dissolve 0.3096 g of cerium acetate in a mixed solvent of 20 mL of ethanol and water (ethanol: water = 5:1), add 34 uL of tetraisopropyl titanate, stir at room temperature for 20 min, then add an ethanol solution of phthalic acid ( 0.1661g of phthalic acid was dissolved in 20mL of ethanol), the above mixture was heated in an oil bath at 50°C for 1h, quenched by adding water, and dried by centrifugation to obtain a white precipitate with a yield of 75%.

[0051] Put the obtained white precipitate in a muffle furnace and sinter at 400°C for 5h to obtain Ti / CeO 2 oxide. Dissolve 40mg of polyvinylpyrrolidone in 80mL of isopropanol and add 100mg of Ti / CeO 2 Oxides, placed in an oil bath at 70°C, added an aqueous solution of sodium tetrachloropalladate (10 mg sodium potassium tetrachloropalladate dissolved in 1.2 mL water), stirred at constant temperature for 4 hours, and then dried by high-speed centri...

Embodiment 3

[0057] 1) Pd loaded Ti / CeO 2 Preparation of nanocomposite catalysts:

[0058] Dissolve 0.3096 g of cerium acetate hydrate in 20 mL of a mixed solvent of ethylene glycol and water (ethylene glycol: water = 10:1), add 5 uLg of titanium tetrachloride, stir at room temperature for 20 min, and then add ethyl citric acid Diol solution (0.192g of citric acid dissolved in 20mL of ethylene glycol), the above mixture was heated in an oil bath at 50°C for 1h, quenched with water, and dried by centrifugation to obtain a white precipitate with a yield of 82%.

[0059] Put the obtained white precipitate in a muffle furnace and sinter at 400°C for 5h to obtain Ti / CeO 2 oxide. Dissolve 80mg of polyvinylpyrrolidone in 80mL of ethylene glycol, add 100mg of Ti / CeO 2 Oxides, placed in an oil bath at 100°C, added an aqueous solution of palladium chloride (10.6 mg of potassium palladium tetrachloropalladate dissolved in 1.2 mL of water), stirred at constant temperature for 4 hours, and then drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com