Fluorescent sensor and sensor system

A fluorescence sensor, fluorescence technology, applied in the field of sensing systems, can solve the problem of difficult to obtain detection sensitivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

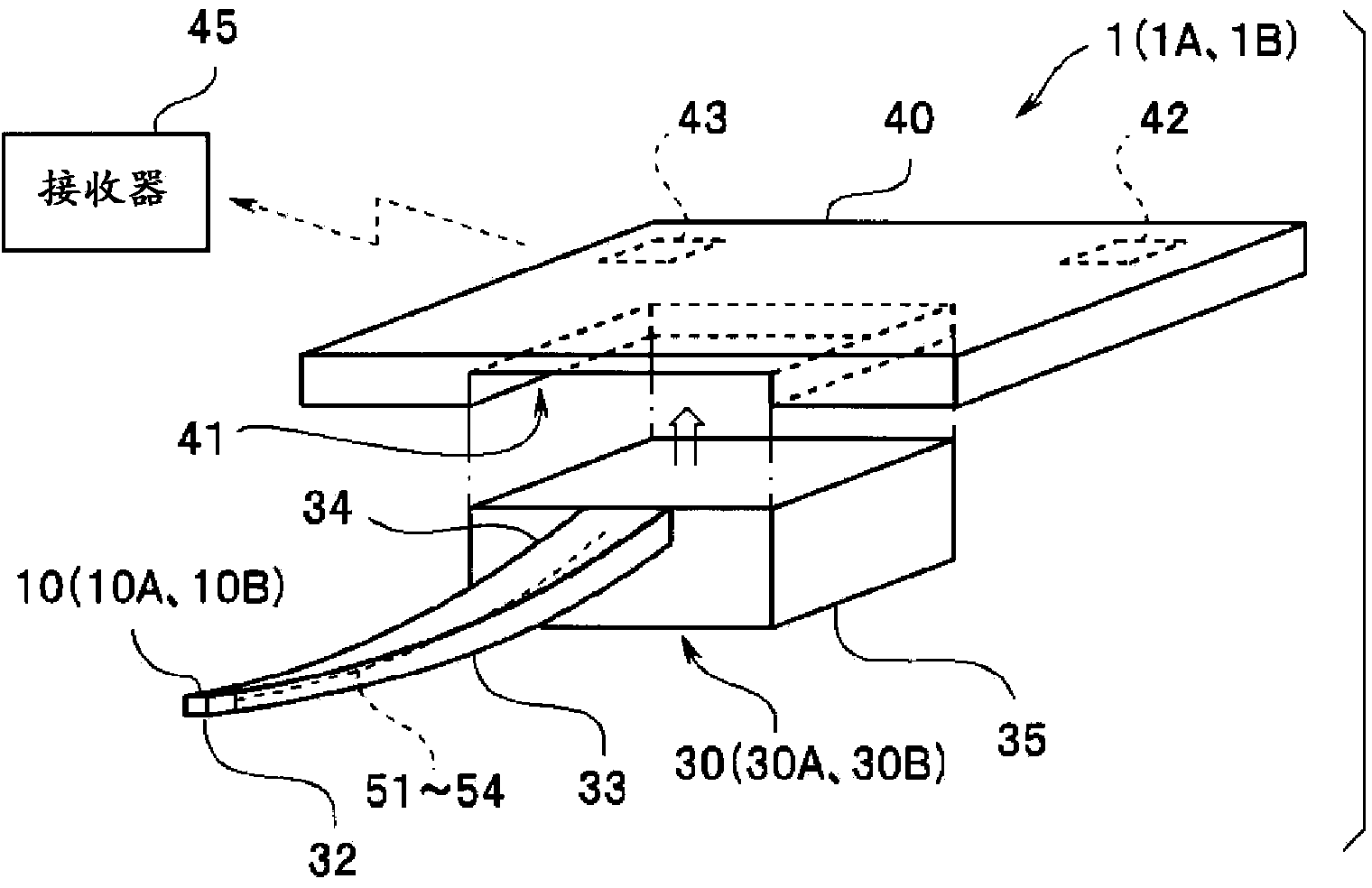

[0027] First, the fluorescence sensor 30 and the sensing system 1 according to the first embodiment of the present invention will be described. like image 3 As shown, the sensing system 1 has a fluorescent sensor 30 , a main body 40 and a receiver 45 that receives and stores signals from the main body 40 . Transmission and reception of signals between the main body 40 and the receiver 45 are performed wirelessly or by wire.

[0028] The fluorescence sensor 30 is composed of a needle portion 34 for puncturing a subject, and a connector portion 35 joined to the rear end portion of the needle portion 34 . The needle portion 34 has an elongated needle body portion 33 and a needle tip portion 32 including the sensing portion 10 as a main functional portion. The needle tip portion 32, the needle body portion 33, and the connector portion 35 may be integrally formed of the same material, or may be manufactured separately and joined together.

[0029] The connector portion 35 is d...

no. 2 Embodiment approach >

[0097] Next, the sensing system 1B and the fluorescence sensor 30B of the second embodiment will be described. Since the fluorescence sensor 30B and the like are similar to the fluorescence sensor 30 and the like, the same components are given the same reference numerals and description thereof will be omitted.

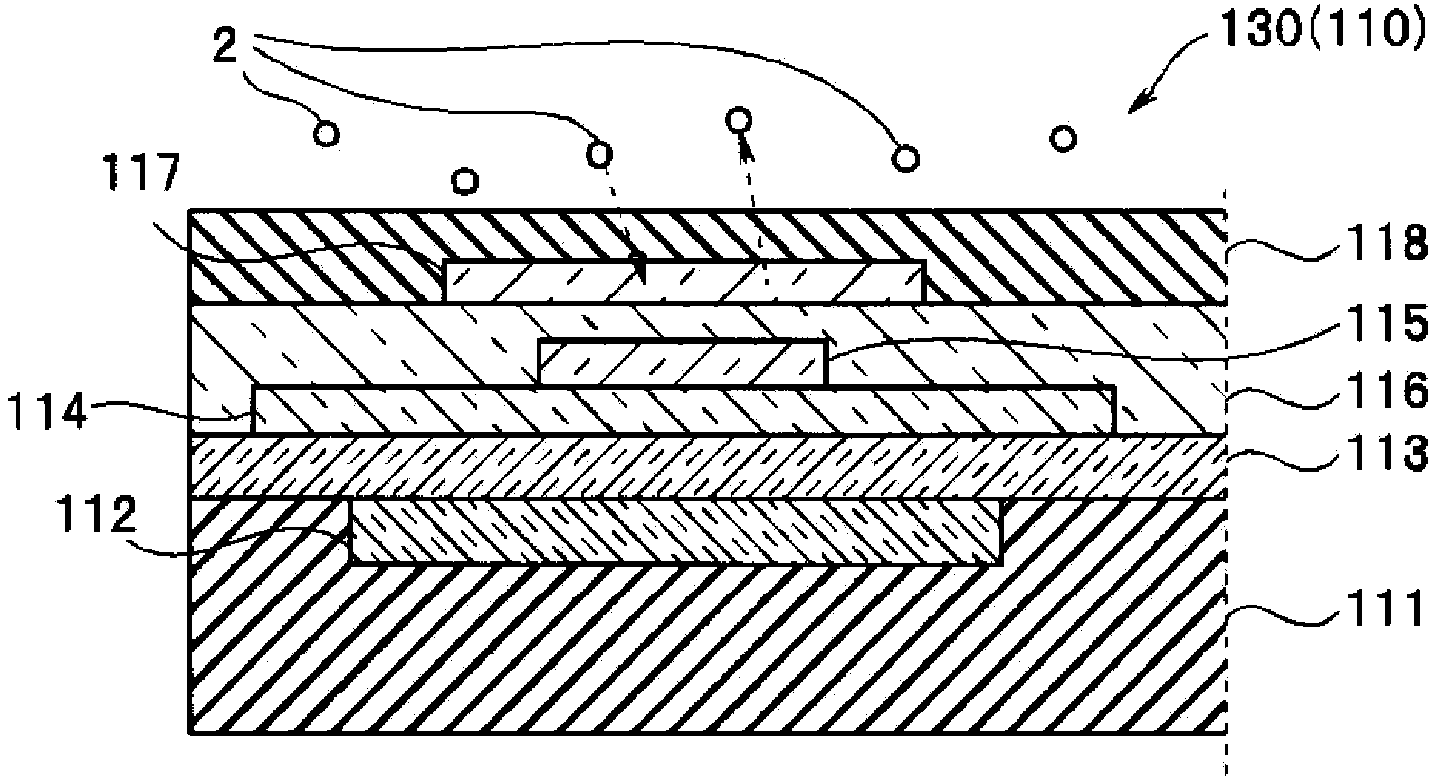

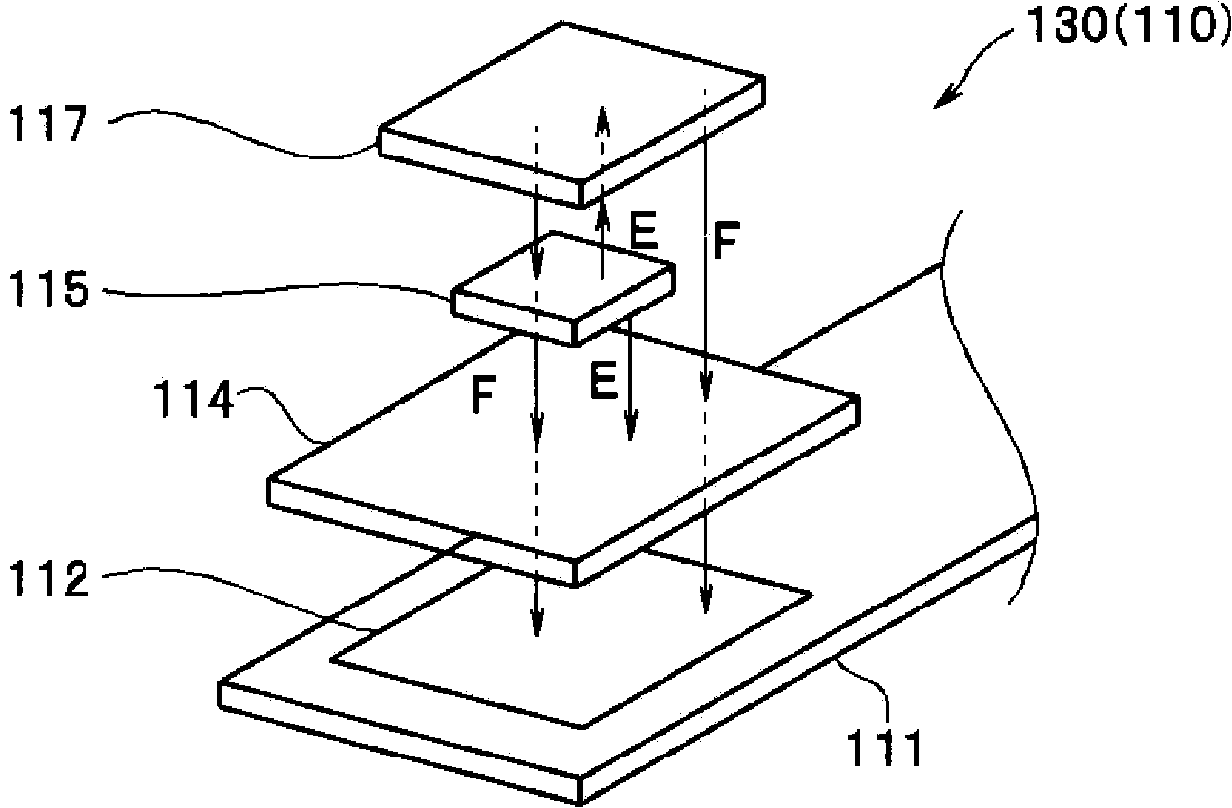

[0098] like Figure 8 As shown, on the detection substrate portion 11B of the sensing portion 10B of the fluorescence sensor 30B, in addition to the PD element 12 as the first photoelectric conversion element for detecting the fluorescence generated by the indicator 17, a detection LED chip 15L is also formed. The generated excitation light is directed to the PD element 12B as the second photoelectric conversion element. That is, the light receiving portion of the first PD element 12 is formed on the wall surface 22 of the through hole 21 of the detection substrate portion 11B, and the light receiving portion of the second PD element 12B is formed on the second main ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com