Nano-spherical mesoporous organic metal catalyst, preparation method and application thereof

An organometallic and catalyst technology, applied in the field of nano-spherical mesoporous organometallic catalysts, to achieve the effect of preventing pollution and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

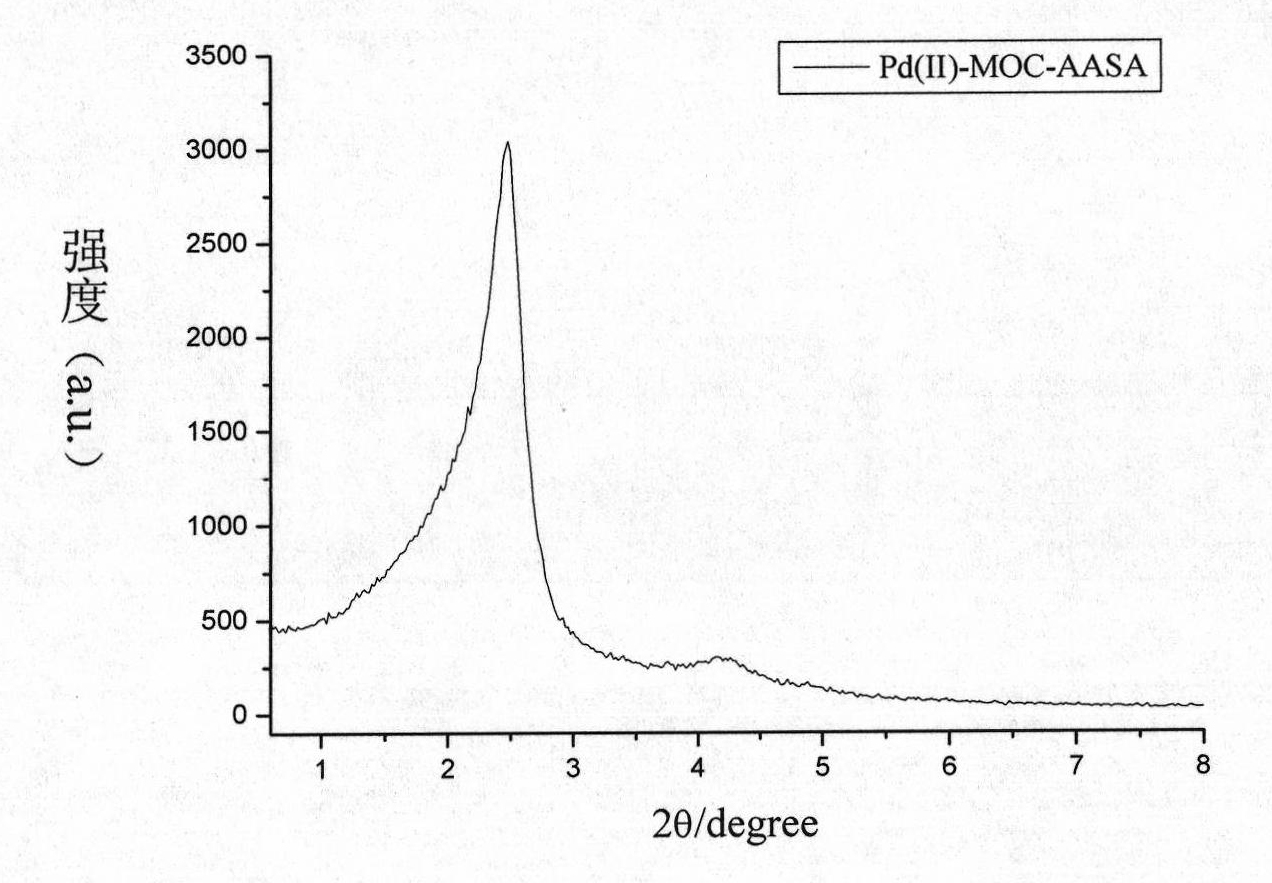

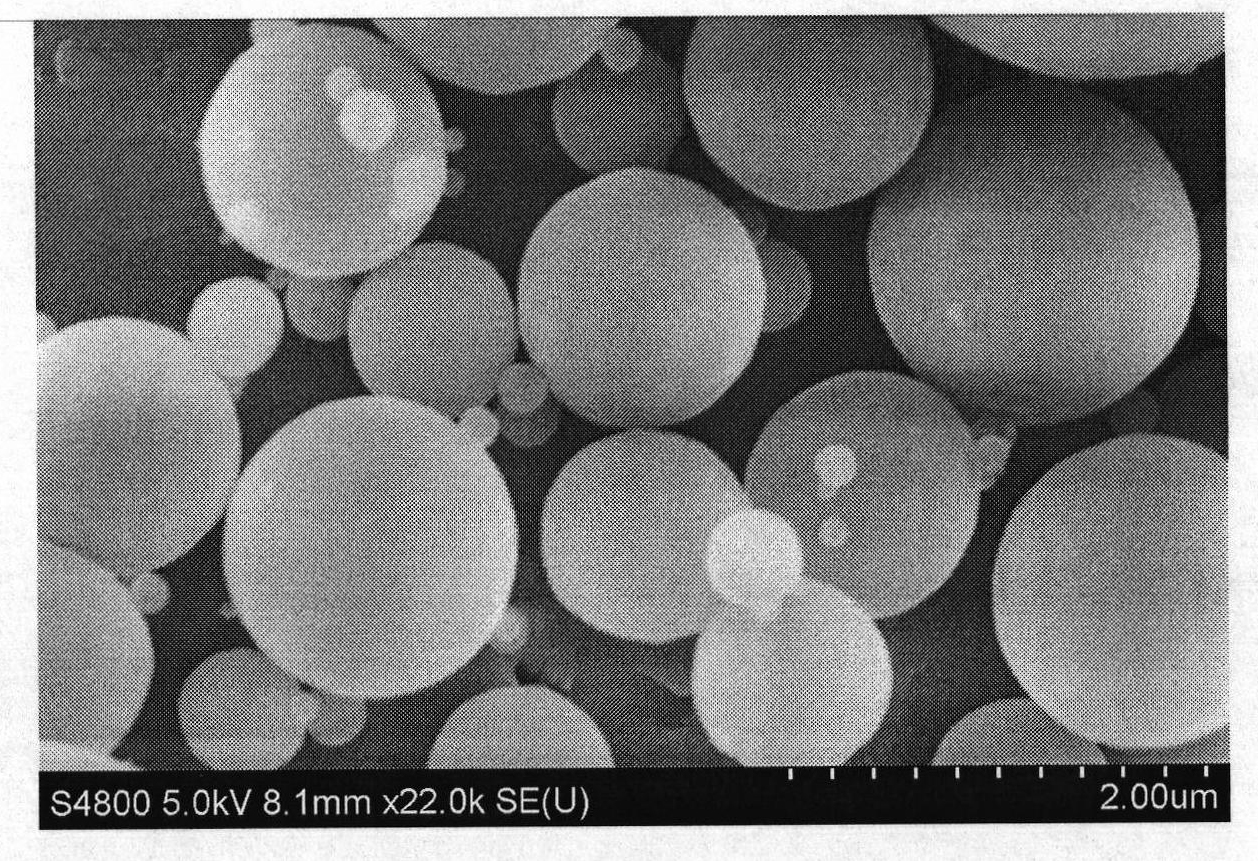

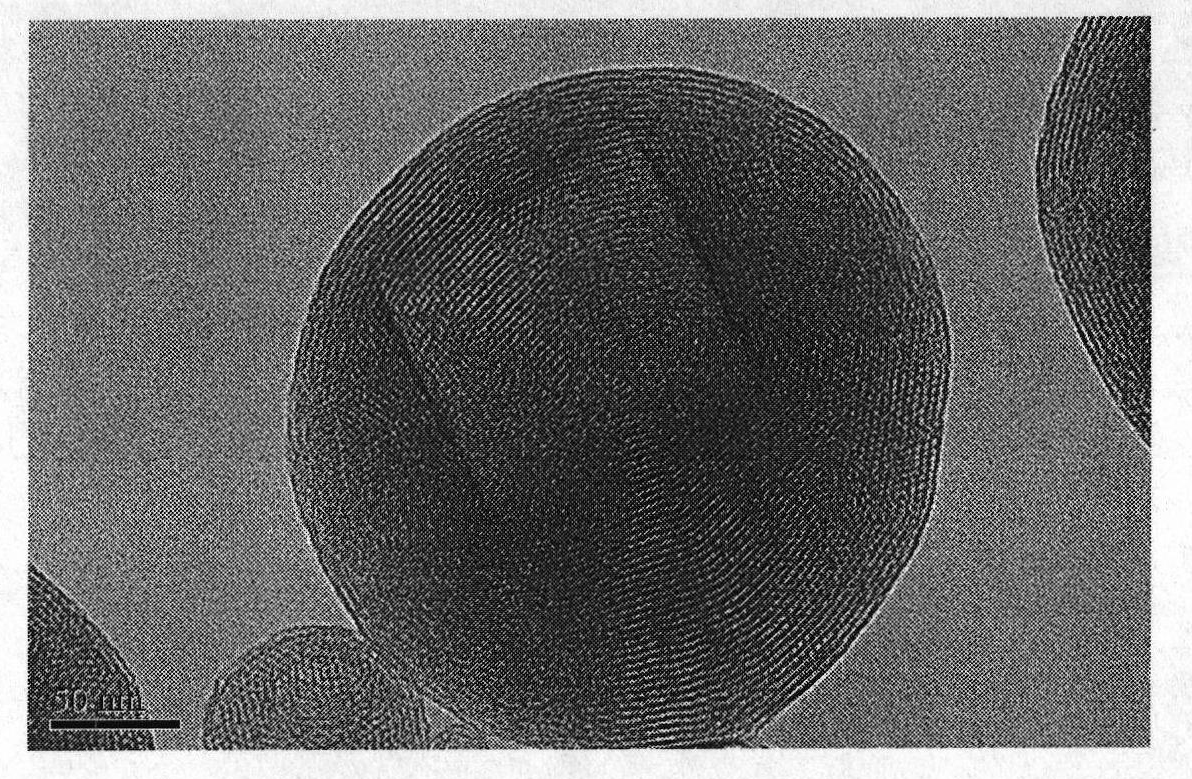

[0028] Preparation of catalyst: At room temperature, a mixture of 1.6g of surfactant CTAB (0.0044mol), 33ml of ethanol (0.57mol), 0.39g of sodium chloride, 6.5ml of water and 0.22ml of aqueous hydrochloric acid (2M) was stirred for 1 After ~6 hours, add 4.3 ml of inorganic silicon source TEOS (0.019 mol), pre-hydrolyze for 1 hour, add 0.27 g (0.00029 mol) of freshly prepared bis-(1-triethoxysilicon-2 dissolved in 2 ml of tetrahydrofuran) -diphenylphosphine)ethane palladium dichloride (organometallic palladium silicon source), continue stirring for 1 to 3 hours until it becomes a homogeneous solution. Subsequently, after spray drying at 573K and 1Mpa pressure, extraction and washing with ethanol at 353K for 24 hours, and vacuum drying, a milky yellow solid powder was obtained, which was a nano-spherical ordered mesoporous organometallic catalyst with high specific surface area. Pd(II)- MOC-AASA said. The content of Pd in the product is 0.14 mmol / g (2% by mass), and the activ...

Embodiment 2

[0032]Take 0.014ml iodobenzene (0.125mmol), 0.014ml phenylacetylene (0.125mmol), 0.030ml n-heptane (internal standard), 0.21ml DBU (1,8-diazacyclo[5,4,0]ten Monoene-7) (1.48mmol), 0.0050g cocatalyst cuprous iodide (0.0259mmol), 4.0ml deionized water, Pd(II)-MOC-AASA prepared in Example 1 (Pd content is 0.005mmol) , and reacted at 353K for 5h. After the obtained product was extracted 5 times with 10ml of toluene, the reaction product was analyzed by gas chromatograph (Agilent GC1790). The analysis results are shown in Table 1.

[0033] Catalytic performance of catalysts in Table 1 Examples 1 and 2

[0034]

Embodiment 3

[0036] Carry out the activity test of benzaldehyde homologues according to the Barbier reaction system of Example 1, take equimolar number of different para-substituents of benzaldehyde as reaction substrates, and reaction conditions and detection means are the same as in Example 1. The analysis results are shown in Table 2.

[0037] The catalytic performance of the catalyst in Table 2 Example 3

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com