Nano-spherical mesoporous organic metal catalyst, preparation method and application thereof

An organometallic and catalyst technology, applied in the field of nano-spherical mesoporous organometallic catalysts, to achieve the effect of simple operation and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

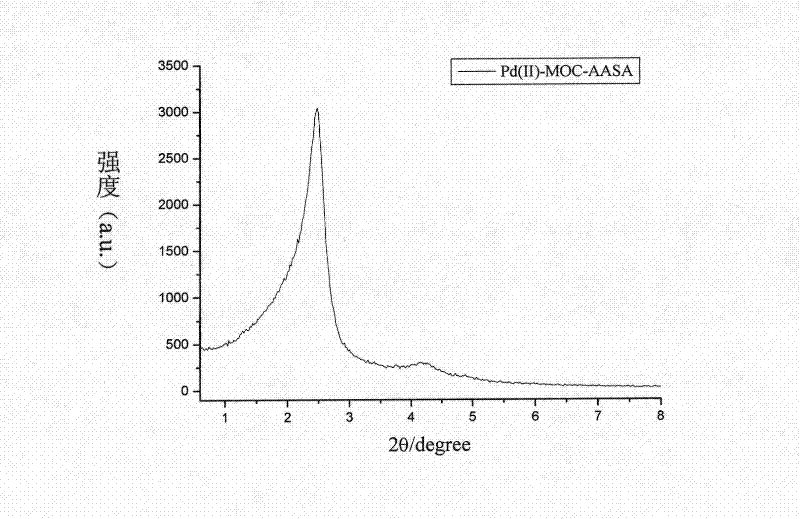

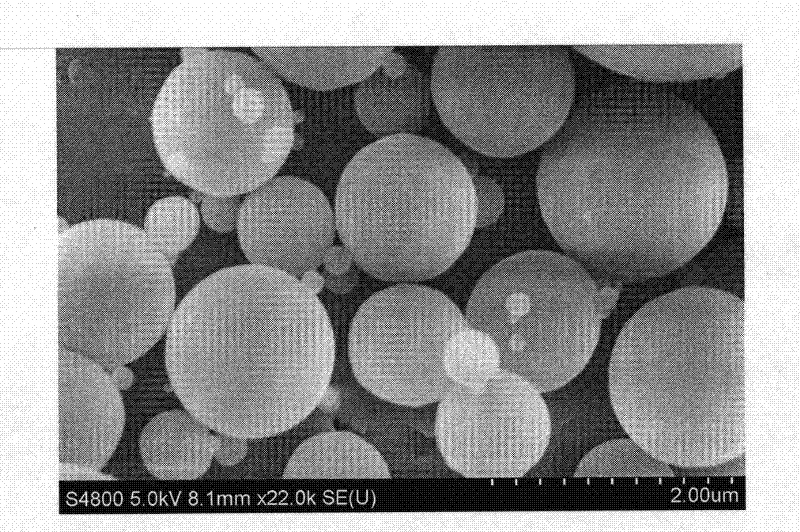

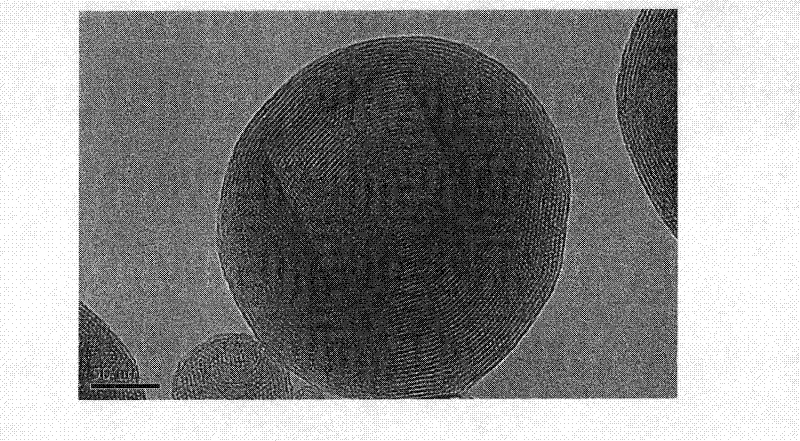

Embodiment 1

[0028] Preparation of the catalyst: at room temperature, the mixed solution of 1.6g surfactant CTAB (0.0044mol), 33ml ethanol (0.57mol), 0.39g sodium chloride, 6.5ml water and 0.22ml hydrochloric acid aqueous solution (2M) was stirred for 1 After ~6 hours, 4.3 ml of inorganic silicon source TEOS (0.019 mol) was added, prehydrolyzed for 1 hour, and 0.27 g (0.00029 mol) of freshly prepared bis-(1-triethoxysilyl-2) dissolved in 2 ml of tetrahydrofuran was added - diphenylphosphine) ethane palladium dichloride (organometallic palladium silicon source), continue to stir for 1 to 3 hours until it becomes a uniform solution. Subsequently, after spray drying at 573K and 1Mpa pressure, extraction and washing with ethanol at 353K for 24 hours, and vacuum drying, the milky yellow solid powder obtained is a nano-spherical ordered mesoporous organometallic catalyst with a high specific surface area. MOC-AASA said. The content of Pd in the product is 0.14mmol / g (2% by mass), and the acti...

Embodiment 2

[0032]Take 0.014ml iodobenzene (0.125mmol), 0.014ml phenylacetylene (0.125mmol), 0.030ml n-heptane (internal standard), 0.21ml DBU (1,8-diazacyclo[5,4,0]deca Monoene-7) (1.48mmol), 0.0050g cocatalyst cuprous iodide (0.0259mmol), 4.0ml deionized water, Pd(II)-MOC-AASA (Pd content is 0.005mmol) prepared in Example 1 , Reaction at 353K for 5h, the resulting product was extracted five times with 10ml toluene, and the reaction product was analyzed by gas chromatography (Agilent GC1790). The analysis results are shown in Table 1.

[0033] Catalytic performance of catalyst in table 1 embodiment 1 and 2

[0034]

Embodiment 3

[0036] Carry out the activity test of benzaldehyde homologue according to the Barbier reaction system of embodiment 1, take the substituent material of different benzaldehyde para-position of equimolar number as reaction substrate, reaction condition and detection means are the same as embodiment 1. The analysis results are shown in Table 2.

[0037] Catalytic performance of catalyst in table 2 embodiment 3

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com