Method for preparing 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone

A technology of cyclopropyl methyl ketone and cyclopropyl, which is applied in the field of preparation of fungicide intermediates, can solve the problems of high price of raw material cyclopropyl acetic acid, high production cost, unsuitability for industrial production, etc., and achieve low raw material price, The effect of low cost and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

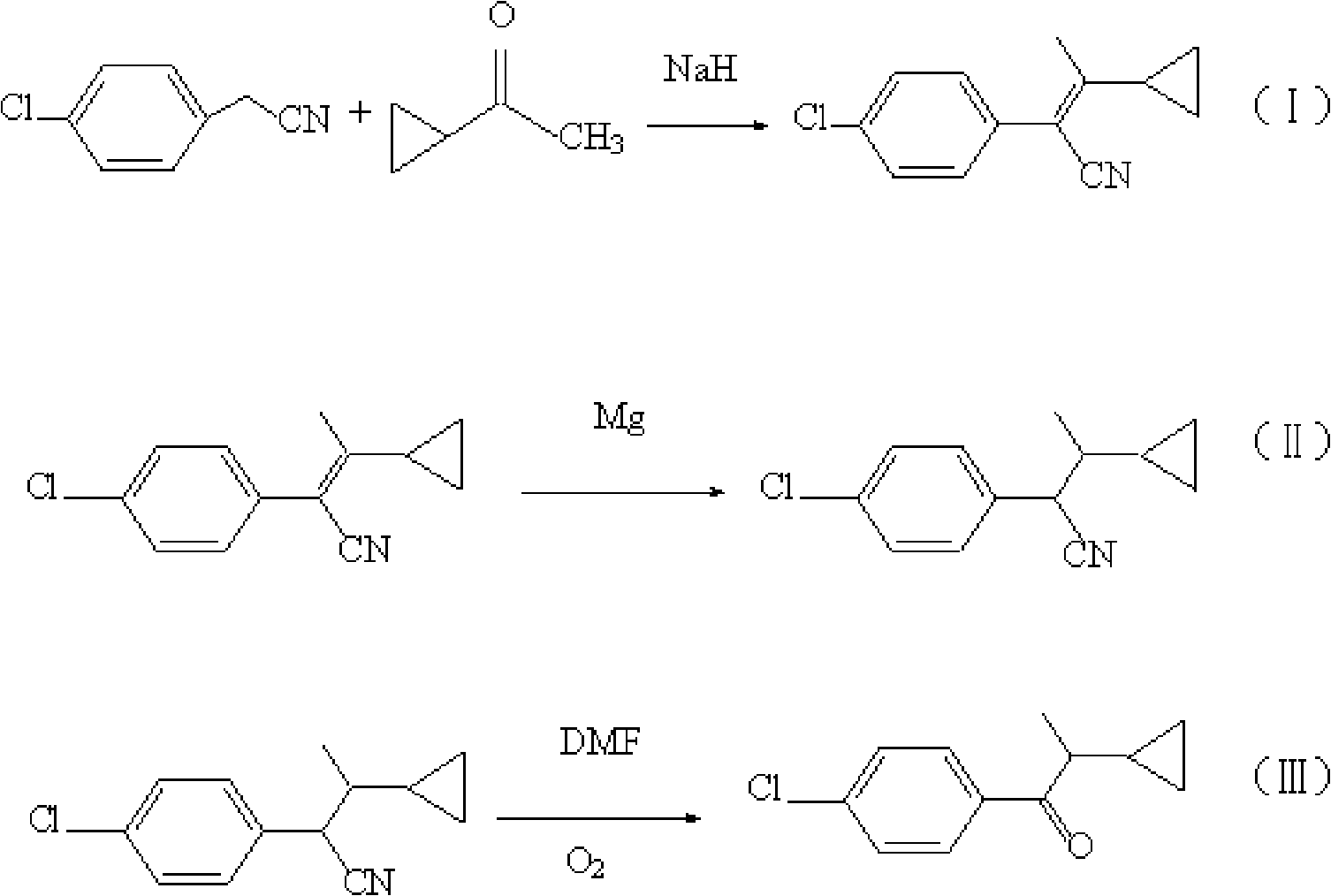

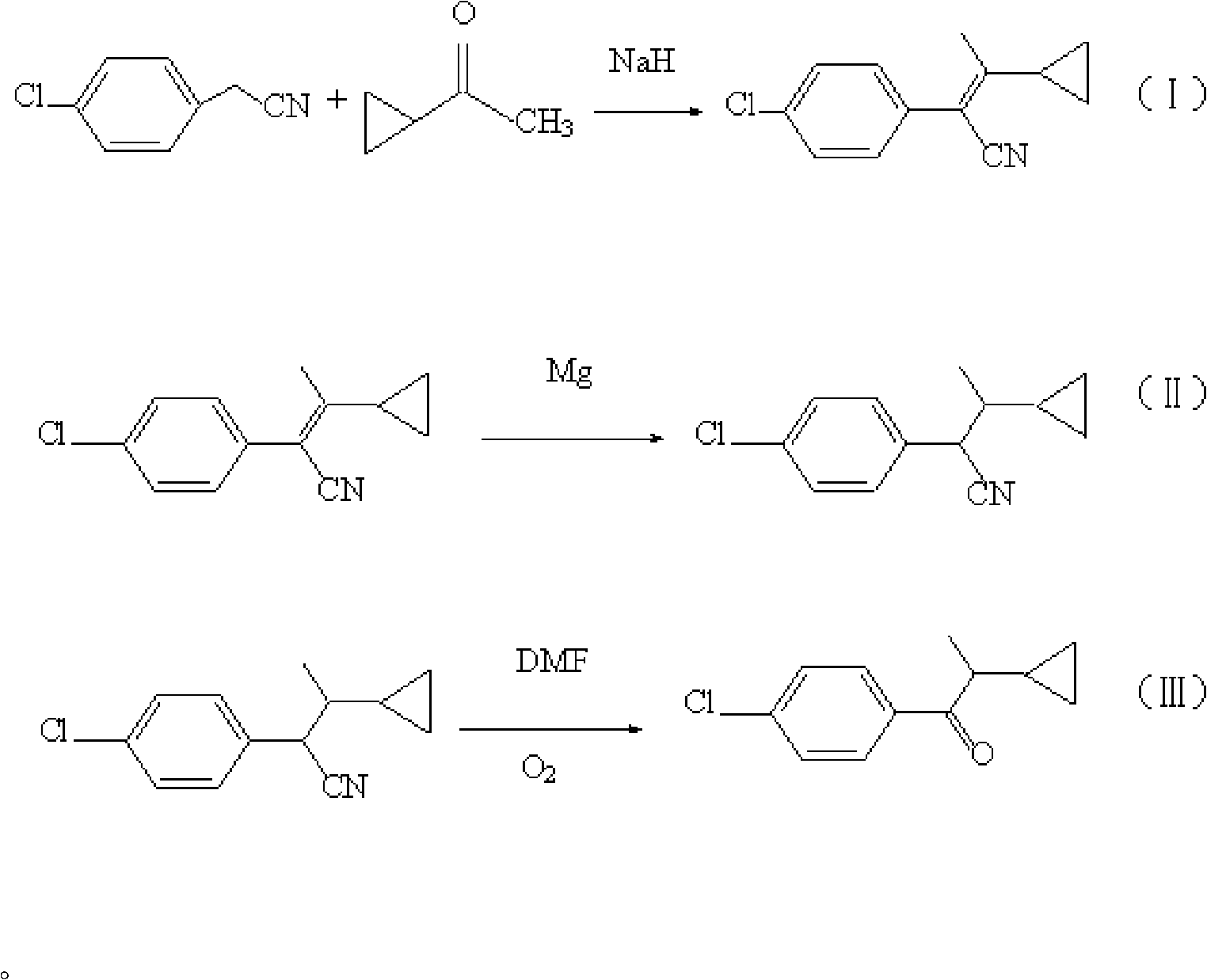

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of the 1-(4-chlorophenyl)-2-cyclopropyl-1-propanone of the present embodiment has the following steps:

[0020] ①In the reaction flask, add 2.3g of catalyst sodium hydride and 80ml of solvent toluene, heat up to 90°C, add dropwise 20ml of toluene, 8.4g of cyclopropyl methyl ketone (0.1mol) and 21g of p-chlorophenylacetonitrile (0.15 mol) of the mixed liquid to carry out the condensation reaction to generate compound I, and continue to carry out the condensation reaction for 4 hours after 30 minutes of dripping. Then perform post-treatment: cool the reaction system to 15°C to 25°C, add 20ml of water, then add 20% sulfuric acid solution dropwise until the solution is neutral, and let the system divide into a water layer and a toluene layer; layer, the toluene layer was washed with water, and the washed toluene layer was distilled under reduced pressure to separate the toluene, and the obtained 20g material was a finished product, wherein the content...

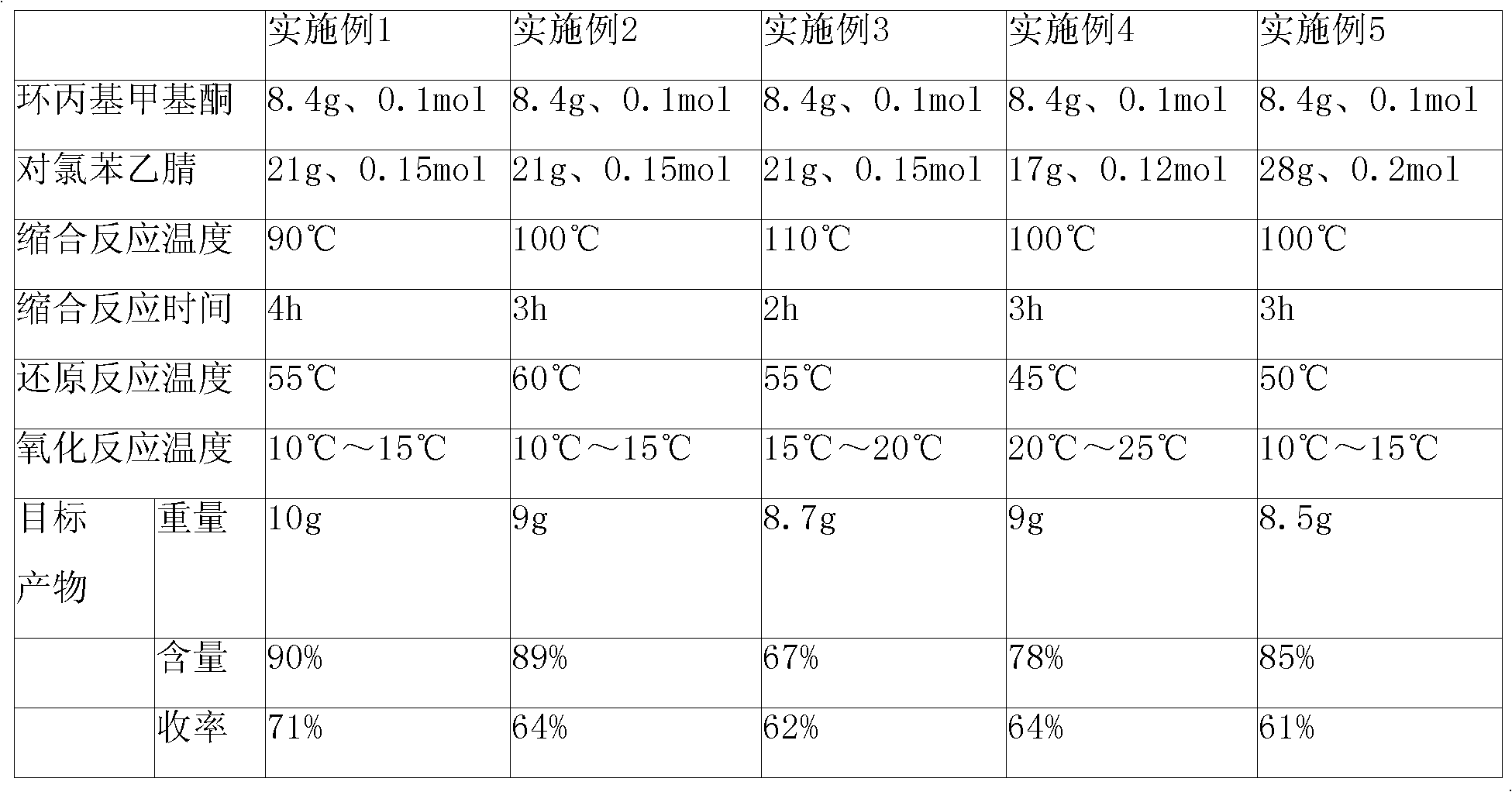

Embodiment 2~ Embodiment 5

[0024] The method of each embodiment is basically the same as that of Example 1, and the differences are shown in Table 1.

[0025] Table 1

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com