Nanofiltration membrane with nanometer hybridized desalination layer

A desalination layer and nanofiltration membrane technology, applied in the field of nanofiltration membranes, can solve problems such as unsatisfactory temperature stability and low pollution capacity, and achieve the effects of improving organic pollution resistance, high removal rate, and high ion selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

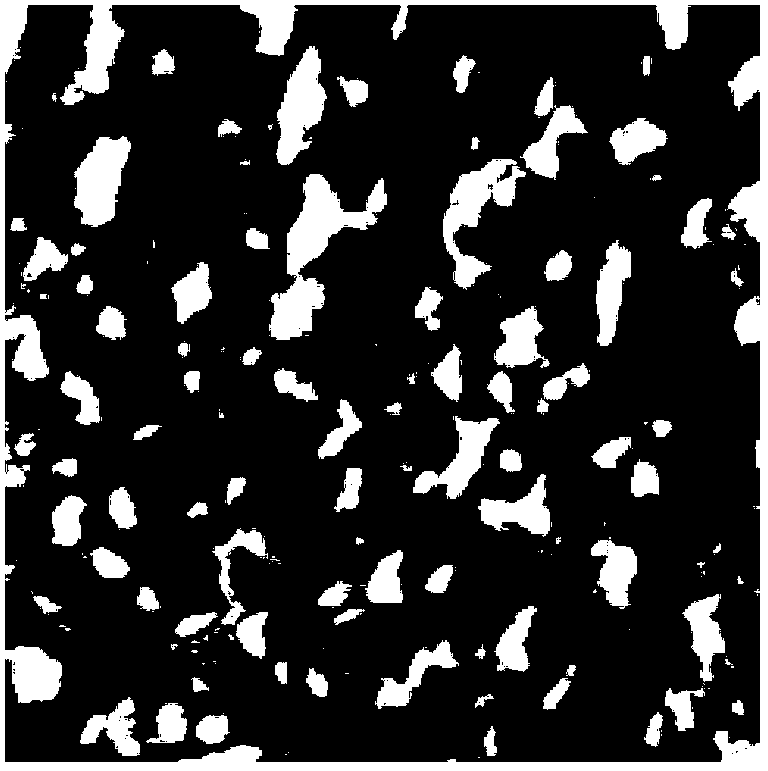

Image

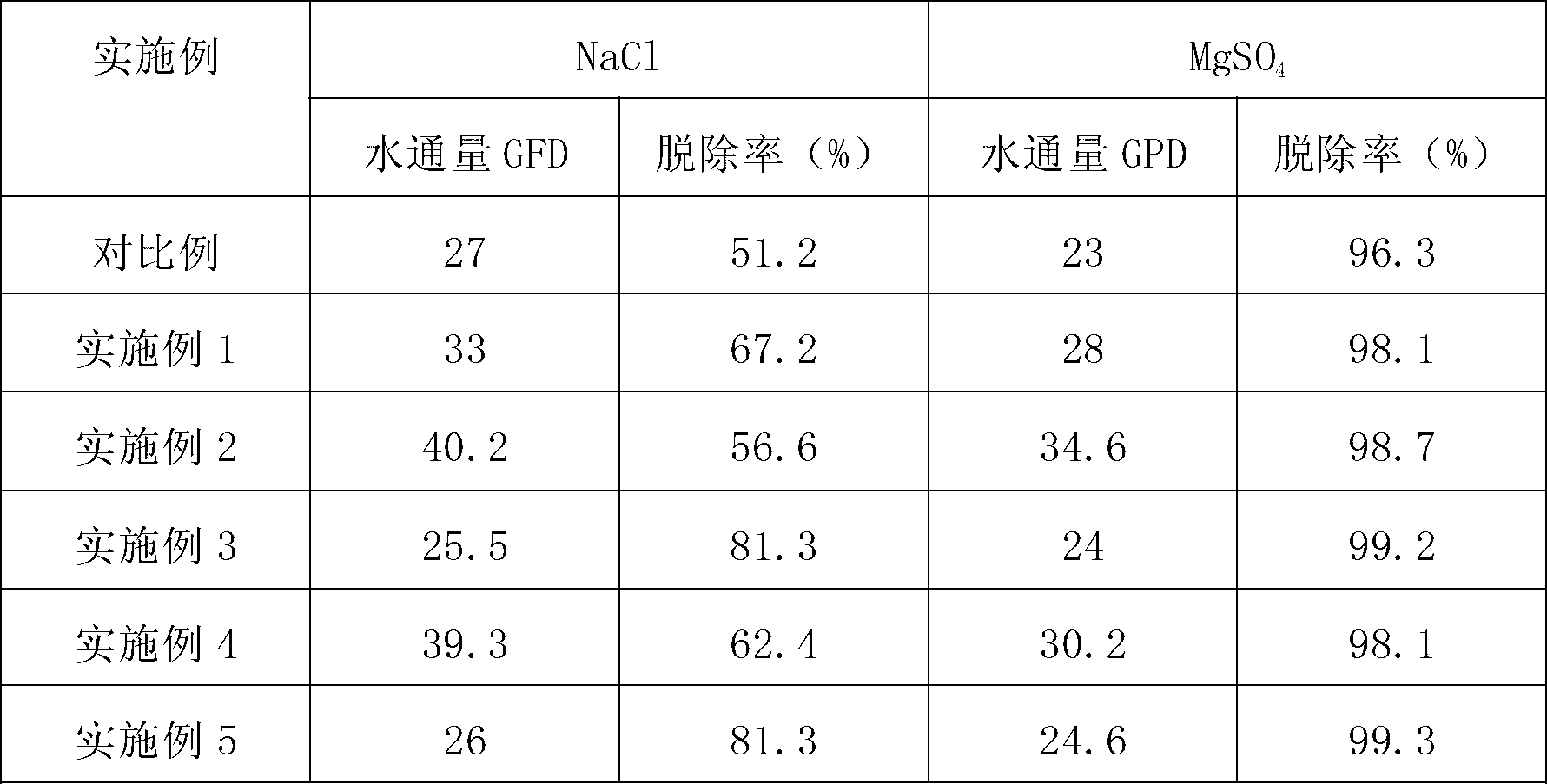

Examples

Embodiment 1

[0032] A nanofiltration membrane with a nano-hybrid desalination layer according to the present invention is mainly prepared according to the following steps:

[0033] (1) Pre-dispersion of nanoparticles: Take 100g of titanium dioxide nanoparticles (particle size: 60nm) and disperse them in 1900g of deionized water. After stirring evenly, use high-power ultrasonic waves for ultrasonic dispersion treatment, and obtain titanium dioxide nano-dispersion liquid after ultrasonication for 6 hours;

[0034] (2) Preparation of solution A: Dissolve 11g of anhydrous piperazine in 989g of the titanium dioxide nano-dispersion described in step (1) to prepare a solution with a m-diphenylamine concentration of 1.1wt%, stir evenly, and after the dissolution is complete, use an appropriate pH The reagent sodium hydroxide was adjusted, the mixed solution was stirred and dissolved, and the pH of the final solution was adjusted to 12 to prepare the A solution, and the obtained A solution was continu...

Embodiment 2

[0040] (1) Pre-dispersion of nanoparticles: Take 100g of titanium dioxide nanoparticles (particle size: 500nm) and disperse them in 1900g of deionized water. After stirring evenly, use high-power ultrasonic waves for ultrasonic dispersion treatment, and obtain titanium dioxide nano-dispersion liquid after ultrasonication for 6 hours;

[0041] (2) Preparation of A solution: Dissolve 11g of anhydrous piperazine in 989g of the titanium dioxide nano-dispersion liquid described in step (1) to prepare a solution with a combined concentration of p-diphenylamine and m-diphenylamine of 0.5wt%, stir evenly, and dissolve completely Finally, after adding an appropriate amount of pH adjusting reagent sodium hydroxide to adjust the final pH of the solution to 11, the A solution was prepared, and the obtained A solution was continued to be treated with ultrasound for 5 h. The concentration of nanoparticles in solution A is 50wt%.

[0042] (3) Preparation of solution B: Dissolve 23.4g of trim...

Embodiment 3

[0047] (1) Pre-dispersion of nanoparticles: Take 100g of titanium dioxide nanoparticles (with a particle size of 200nm) and disperse them in 1900g of deionized water, after stirring evenly, use high-power ultrasonic waves for ultrasonic dispersion treatment, and obtain titanium dioxide nano-dispersions after ultrasonication for 6 hours;

[0048] (2) Preparation of A solution: Dissolve 11g of anhydrous piperazine in 989g of the titanium dioxide nano-dispersion liquid described in step (1) to prepare a solution with a piperazine concentration of 1.5wt%, stir evenly, and after dissolution is complete, add an appropriate amount of pH adjustment After adjusting the pH of the final solution to 11 with sodium hydroxide as a reagent, the A solution was prepared, and the obtained A solution was continued to be treated with ultrasound for 2 h. The concentration of nanoparticles in solution A is 20wt%.

[0049] (3) Preparation of solution B: Dissolve 23.4g of trimesoyl chloride in 976.6g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com