Sulfonated polyether ether ketone-based blend ion exchange membrane for flow battery, and preparation method thereof

A technology of sulfonated polyetheretherketone and ion-exchange membrane, which is applied in the field of ion-exchange membranes, can solve problems such as unfavorable application, decreased mechanical properties, and high vanadium ion permeability, and achieve uniform properties, prolong life, and improve thermal stability. The effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] In some embodiments, there is also provided a method for manufacturing a flow battery, including the steps of using the preparation method to prepare a sulfonated polyether ether ketone-based blended ion exchange membrane for a flow battery and using the flow battery Steps for assembling a battery with a sulfonated polyetheretherketone-based blended ion-exchange membrane.

[0054] The following exemplifies the preparation method of the sulfonated polyetheretherketone-based blended ion-exchange membrane for the flow battery and the preferred examples of the prepared ion-exchange membrane, and the application of the prepared ion-exchange membrane to the flow battery performance and advantages.

example 1

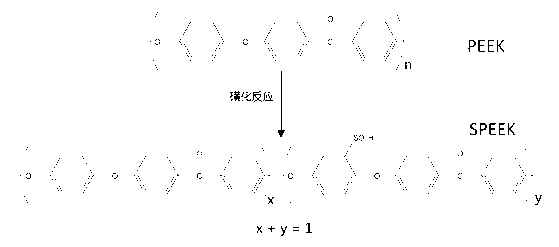

[0056] (1) Add 25 g of polyetheretherketone dried under vacuum at 80 °C for 12 hours to 250 mL of concentrated sulfuric acid with a mass percentage of 95-98 wt% (the mass-volume ratio is 0.1 g mL -1 ), sulfonated at 50 °C for 6 hours, the product was dissolved in 25 mL min -1 Add it into a stirring ice-water bath at a high speed, wash 6~7 times until the pH of the washing solution is 6~7, filter the sulfonated product under reduced pressure, and dry it at 80 °C for 12 hours to obtain a sulfonated product with a sulfonation degree of 73%. Polyetheretherketone.

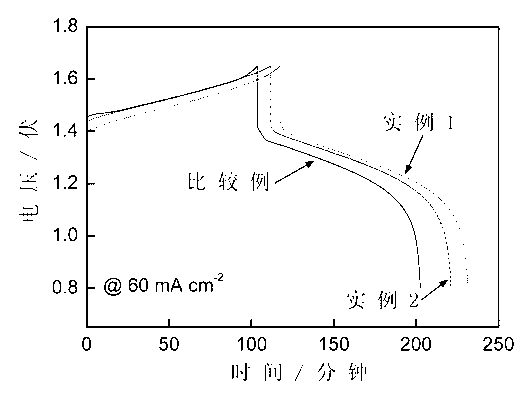

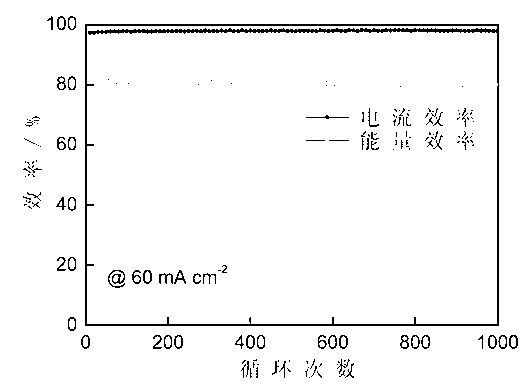

[0057] (2) The sulfonated polyether ether ketone prepared in step (1) is 85 wt% by mass, and the polyvinylidene fluoride is 15 wt% by mass (the total mass of sulfonated polyether ether ketone and polyvinylidene fluoride is 1.5 g) Add it to 10 mL of N,N-dimethylformamide, and stir thoroughly at 25 °C for 12 hours to make a blend solution; remove the bubbles and impurities from the blend solution, and use flow to clean t...

example 2

[0060] The preparation method of the sulfonated polyetheretherketone-polyvinylidene fluoride blended ion-exchange membrane of this example is the same as example 1, and the polyylidene fluoride in the prepared sulfonated polyetheretherketone-polyvinylidene fluoride blended ion-exchange membrane The ethylene content was 10 wt%, and the thickness of the blended ion-exchange membrane was 75 μm. A single cell of an all-vanadium redox flow battery was assembled with this blended ion-exchange membrane, and other assembly conditions and test conditions were the same as in Example 1 (excluding cycle charge-discharge life test). The Coulombic efficiency of the single cell is 97.0%, the voltage efficiency is 82.4%, and the energy efficiency is 79.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com