Three-dimensional ordered porous bracket material of chitosan fiber/bioactive glass and preparation method of three-dimensional ordered porous bracket material

A bioactive glass and chitosan fiber technology, applied in the field of artificial bone repair materials, can solve the problems of lack of three-dimensional connected macroporous structure and cannot meet the mechanical strength of macroporous structure at the same time, so as to achieve good biological activity and good Effect of improving elastic modulus and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

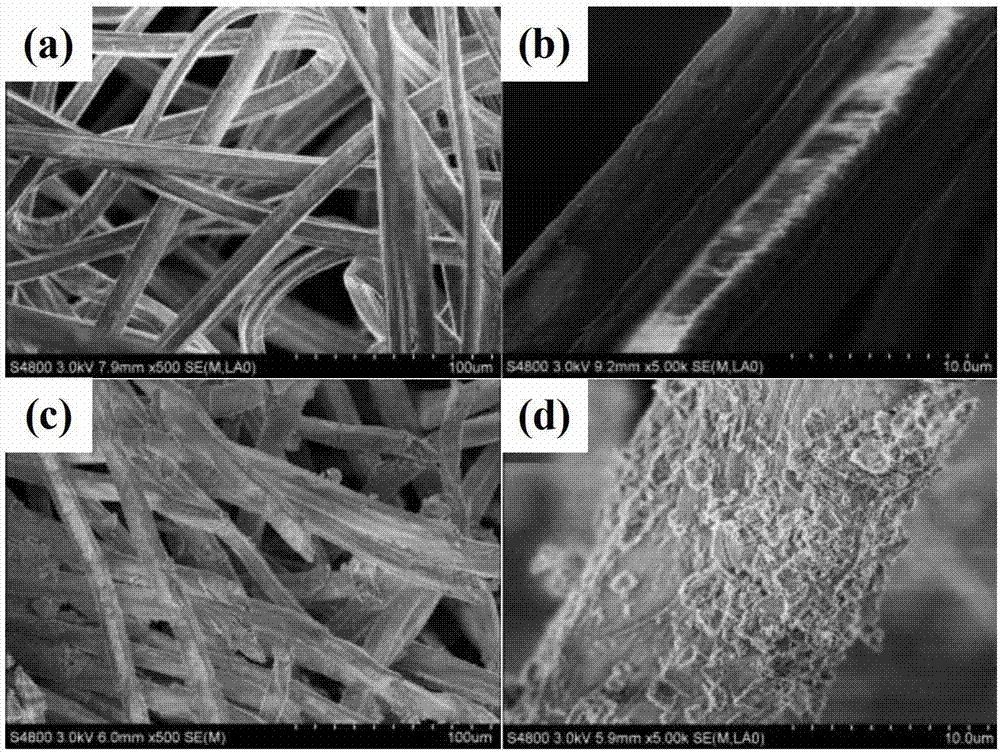

[0031] 1. Preparation of chitosan fiber cloth layer:

[0032] Take the weight as 100g / m 2 The chitosan fiber is loosely mixed by hand, and is combed and loosened with a small flat carding machine; 3 pieces of fiber webs are taken, and the grammage of each piece of fiber is 550g / m 2 , Lay the web in parallel by hand, so that the fibers are arranged longitudinally; then use a needle punching machine for reinforcement, the frequency of acupuncture is 1200 punches / min, and the depth of acupuncture is 3mm, and the chitosan fiber cloth is cut into bone damage repair materials. Cut into a square with a side length of 2cm and a thickness of 3mm. The pore size of the fiber cloth is 200-300μm. Ultrasonic cleaning with absolute ethanol for 30min, then rinse with deionized water several times until it is clean, and place in an oven. Dry at 60°C for later use;

[0033] 2. Preparation of bioactive glass powder:

[0034] The bioactive glass was prepared by the sol-gel method. The specific...

Embodiment 2

[0046] 1. Preparation of chitosan fiber cloth layer:

[0047] Take the gram weight as 80g / m 2 The chitosan fiber is loosely mixed by hand, and is combed and loosened with a small flat carding machine; 3 pieces of fiber webs are taken, and the grammage of each piece of fiber is 550g / m 2 Lay the web in parallel by hand, so that the fibers are arranged longitudinally; then use a needle punching machine for reinforcement, the frequency of needle punching is 1000 punches / min, and the depth of needle punching is 4mm, and the chitosan fiber cloth is cut into bone damage repair materials. Cut into a square with a side length of 2cm and a thickness of 3mm. The pore size of the fiber cloth is 300-500μm. Ultrasonic cleaning with absolute ethanol for 30min, then rinse with deionized water several times until it is clean, and place it in an oven. Dry at 60°C for later use;

[0048] Step (2) and step (3) are the same as in Example 1.

Embodiment 3

[0050] 1. Preparation of chitosan fiber cloth layer:

[0051] Take the weight as 100g / m 2 The chitosan fiber is manually loosened and mixed, and combed and loosened with a small flat carding machine; 4 fiber webs are taken, and the grammage of each fiber is 550g / m 2 Lay the web in parallel by hand so that the fibers are arranged longitudinally; then use a needle punching machine for reinforcement, the frequency of acupuncture is 1200 punches / min, and the depth of needle punching is 4 mm. Shape, cut into a square with a side length of 2cm and a thickness of 3mm, the pore size of the fiber cloth is 200-300μm, ultrasonic cleaning with absolute ethanol for 30min, and then rinsed with deionized water several times until it is clean, placed in an oven, 60 Dry at ℃ for later use;

[0052] Step (2) and step (3) are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com