Method for making core-shell polyhedral oligomeric silsesquioxane (POSS) coated multi-walled carbon nanotube (MWNT)

A technology of multi-walled carbon nanotubes and carbon nanotubes, which is applied in the treatment of dyed organosilicon compounds, fibrous fillers, etc., can solve problems such as performance damage, difficulty in large-scale production, and carbon nanotube structure breakage, and achieve operational Simple and low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

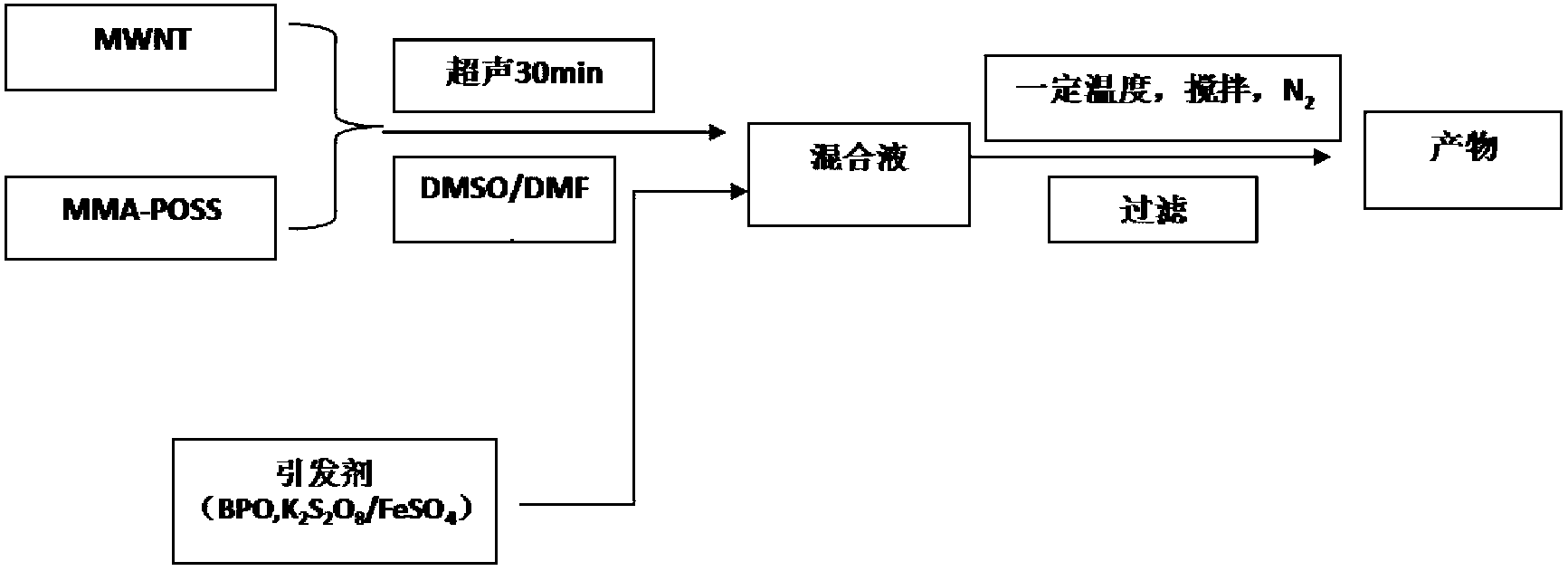

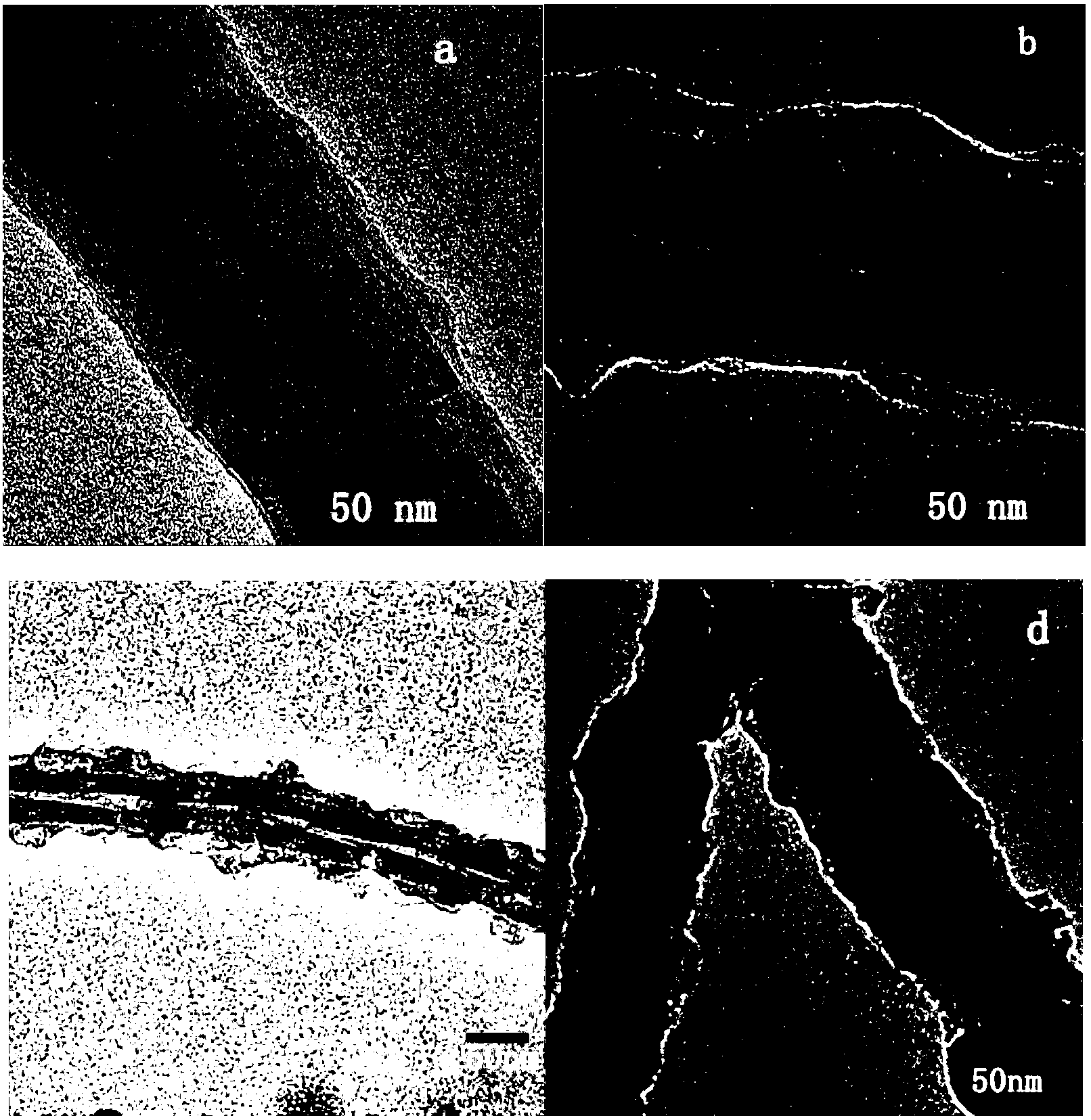

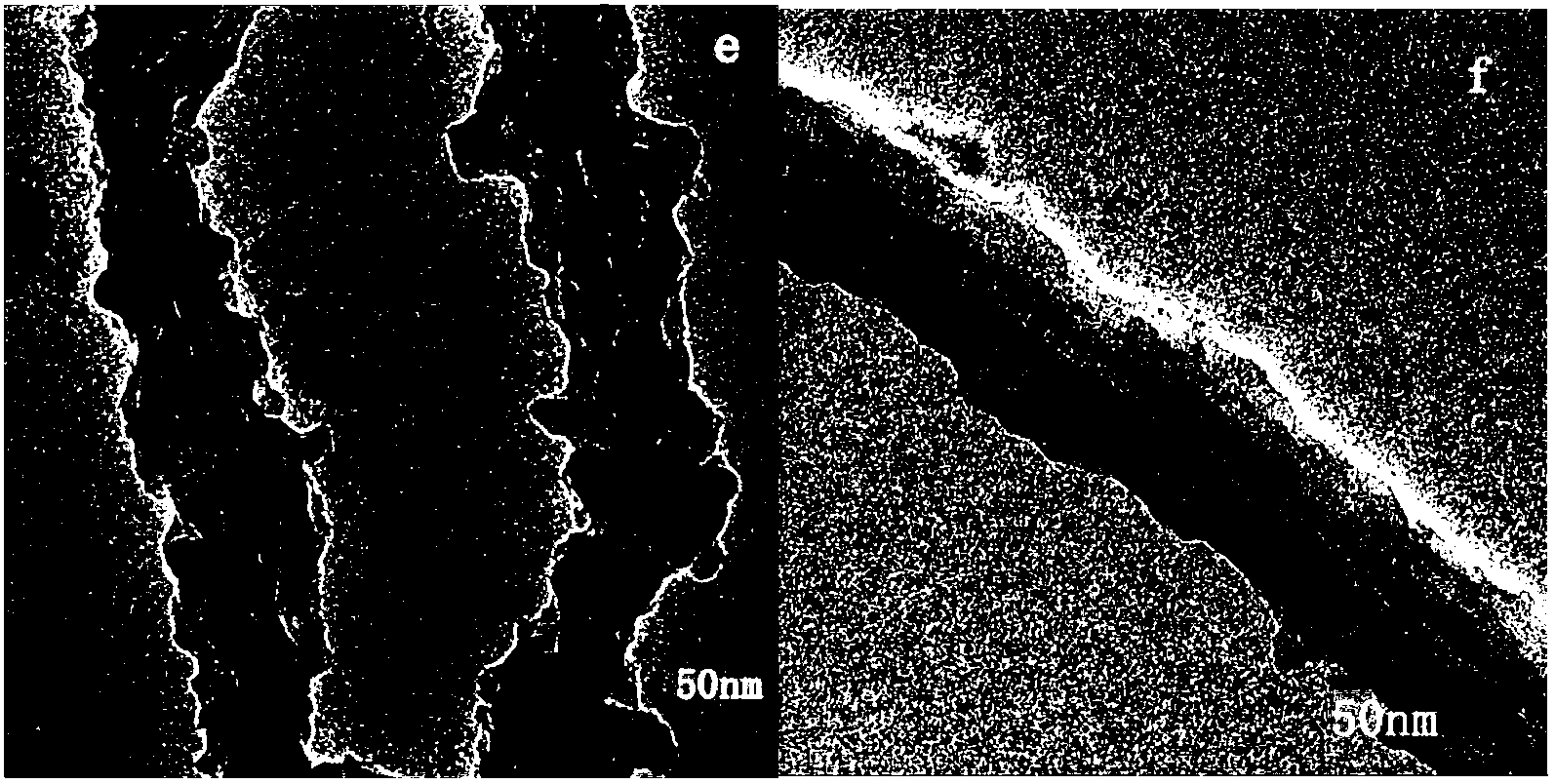

[0019] Weigh 50 mg of carbon nanotubes, place them in a three-necked flask, add 20 ml of DMF as a solvent, and ultrasonically disperse for 15 minutes. Weigh 250 mg of mma-POSS, add it to the above three-necked flask, and sonicate it for 15 minutes. Add 80ml DMF solvent and sonicate for 15min. Move the three-necked flask into an oil bath, under the protection of nitrogen, add initiator benzoyl peroxide (12.5mg), and stir at room temperature for 15 minutes. The temperature was increased to 80°C, and the reaction was carried out for 8 hours to stop the reaction. The product was obtained by suction filtration, followed by ultrasonic washing with N,N-dimethylformamide, dimethyl sulfoxide, deionized water, ethanol, and chloroform for 15 minutes, and finally suction filtration to obtain the target product. figure 2 (A) is the core-shell composite powder of mma-POSS coated carbon nanotubes prepared in this example (the specific flow chart is shown in Figure (1)). It can be seen from...

Embodiment 2

[0021] Weigh 50 mg of carbon nanotubes, place them in a three-necked flask, add 20 ml of DMF as a solvent, and ultrasonically disperse for 10 minutes. Weigh 500 mg of mma-POSS, add it to the above three-necked flask, and sonicate it for 15 minutes. Add 80ml DMF solvent and sonicate for 15min. Move the three-necked flask into an oil bath, under the protection of nitrogen, add initiator benzoyl peroxide (12.5mg), and stir at room temperature for 15 minutes. The temperature was increased to 80°C, and the reaction was carried out for 8 hours to stop the reaction. The product was obtained by suction filtration, followed by ultrasonic washing with N,N-dimethylformamide, dimethyl sulfoxide, deionized water, ethanol, and chloroform for 15 minutes, and finally suction filtration to obtain the target product. figure 2 (B) is the mma-POSS core-shell composite powder coated with carbon nanotubes prepared in this example. It can be clearly seen that there is a thick coating material on t...

Embodiment 3

[0023] Weigh 50 mg of carbon nanotubes, place them in a three-necked flask, add 20 ml of DMSO as a solvent, and ultrasonically disperse for 10 minutes. Weigh 100 mg of mma-POSS, add it to the above three-necked flask, and sonicate it for 15 minutes. Add 80ml of DMSO solvent and ultrasonic for 15min. Move the three-necked flask into an oil bath, and under the protection of nitrogen gas, add an initiator composed of ferrous sulfate / potassium persulfate, including 13 mg of ferrous sulfate and 19.5 mg of potassium persulfate, and stir at room temperature for 15 minutes. The temperature was increased to 60°C, and the reaction was conducted for 8 hours to stop the reaction. The product was obtained by suction filtration, followed by ultrasonic washing with N,N-dimethylformamide, dimethyl sulfoxide, deionized water, ethanol, and chloroform for 15 minutes, and finally suction filtration to obtain the target product. figure 2 (C) is the core-shell composite powder of mma-POSS coated c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com