Reduced graphene oxide/polyacrylonitrile composite fiber and preparation method thereof

A technology of polyacrylonitrile fiber and polyacrylonitrile, which is applied in the field of reduced graphene oxide/polyacrylonitrile composite fiber and its preparation, can solve the problem that the electrical conductivity of PAN fiber cannot be effectively improved, and achieves improved electrical conductivity and effective functional compounding. , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of preparation method of reduced graphene oxide / polyacrylonitrile composite fiber, concrete steps are as follows:

[0045] (1) The polyacrylonitrile that the first monomer is acrylonitrile, the second monomer is methyl methacrylate and the third monomer is DEMA is dissolved in an aqueous solution of 50 wt% sodium thiocyanate to obtain a spinning stock solution , where acrylonitrile accounts for 85% of the mass fraction of polyacrylonitrile, methyl methacrylate accounts for 14% of the mass fraction of polyacrylonitrile, DEMA accounts for 1% of the mass fraction of polyacrylonitrile, and polyacrylonitrile in the spinning dope The quality score of 20%;

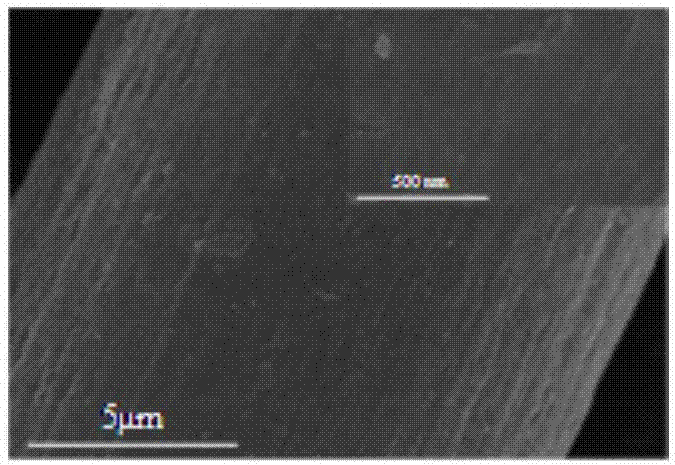

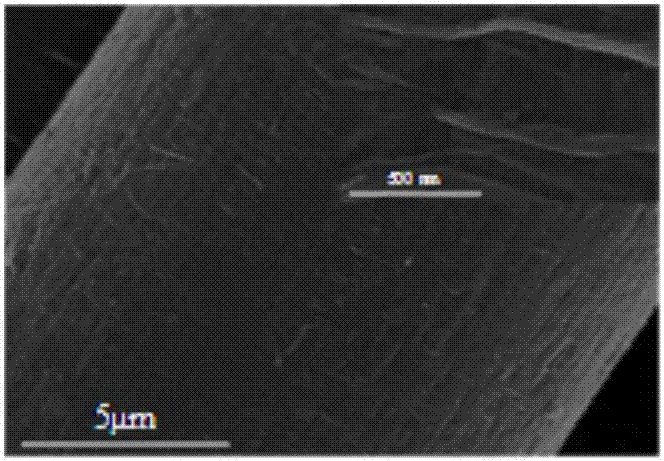

[0046] (2) The spinning stock solution enters the coagulation bath, washing tank and stretching bath through the spinneret, and after being stretched 9 times, the polyacrylonitrile fiber containing the amino group is collected by a winder, and the polyacrylonitrile fiber containing the amino group The SEM picture i...

Embodiment 2

[0051] A kind of preparation method of reduced graphene oxide / polyacrylonitrile composite fiber, concrete steps are as follows:

[0052] (1) The polyacrylonitrile that the first monomer is acrylonitrile, the second monomer is methyl methacrylate and the third monomer is DEMA is dissolved in an aqueous solution of 52 wt% sodium thiocyanate to obtain a spinning stock solution , where acrylonitrile accounts for 86% of the mass fraction of polyacrylonitrile, methyl methacrylate accounts for 13.5% of the mass fraction of polyacrylonitrile, DEMA accounts for 0.5% of the mass fraction of polyacrylonitrile, and polyacrylonitrile in the spinning dope The mass fraction of 10%;

[0053] (2) The spinning stock solution enters the coagulation bath, washing tank and stretching bath through the spinneret, and after being stretched 3 times, the polyacrylonitrile fiber containing amino groups is collected by a winder, wherein the coagulation bath has a temperature of 0 ° C, The aqueous soluti...

Embodiment 3

[0058] A kind of preparation method of reduced graphene oxide / polyacrylonitrile composite fiber, concrete steps are as follows:

[0059] (1) the polyacrylonitrile that the first monomer is acrylonitrile, the second monomer is methyl methacrylate and the third monomer is DEMA is dissolved in the aqueous solution that is the sodium thiocyanate of 54wt% to obtain spinning dope , wherein acrylonitrile accounts for 87% of the mass fraction of polyacrylonitrile, methyl methacrylate accounts for 11% of the mass fraction of polyacrylonitrile, DEMA accounts for 2% of the mass fraction of polyacrylonitrile, and polyacrylonitrile in the spinning dope The quality score is 30%;

[0060] (2) The spinning stock solution enters the coagulation bath, water washing tank and stretching bath through the spinneret, and after being stretched 12 times, the polyacrylonitrile fiber containing amino groups is collected by a winder, wherein the coagulation bath has a temperature of 25°C, An aqueous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com