Carbon fiber surface treating agent based on graphene oxide and treatment method thereof

A technology of surface treatment agent and treatment method, which is applied in fiber treatment, carbon fiber, textiles and papermaking, etc., can solve the problems of increasing process difficulty and cost, and achieve the effect of retaining mechanical properties, not easy to peel off, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

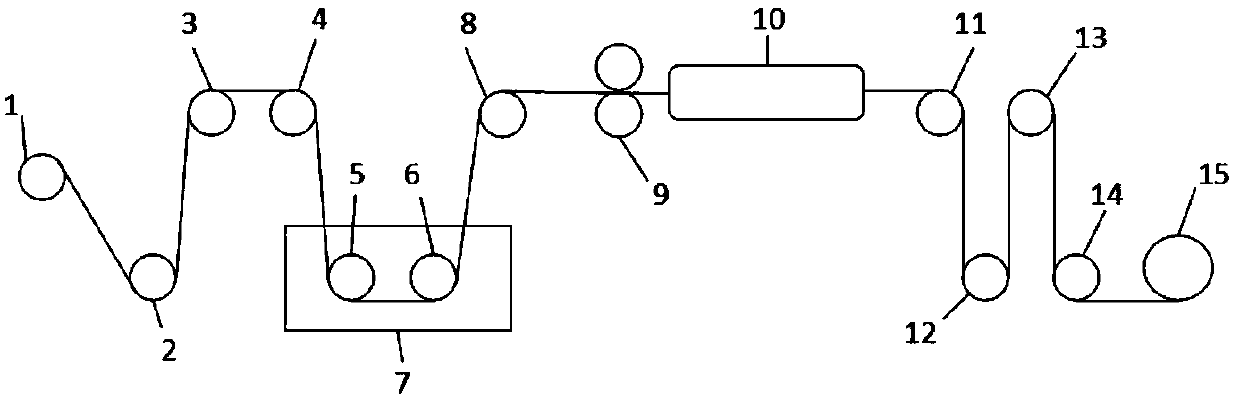

Method used

Image

Examples

Embodiment 1

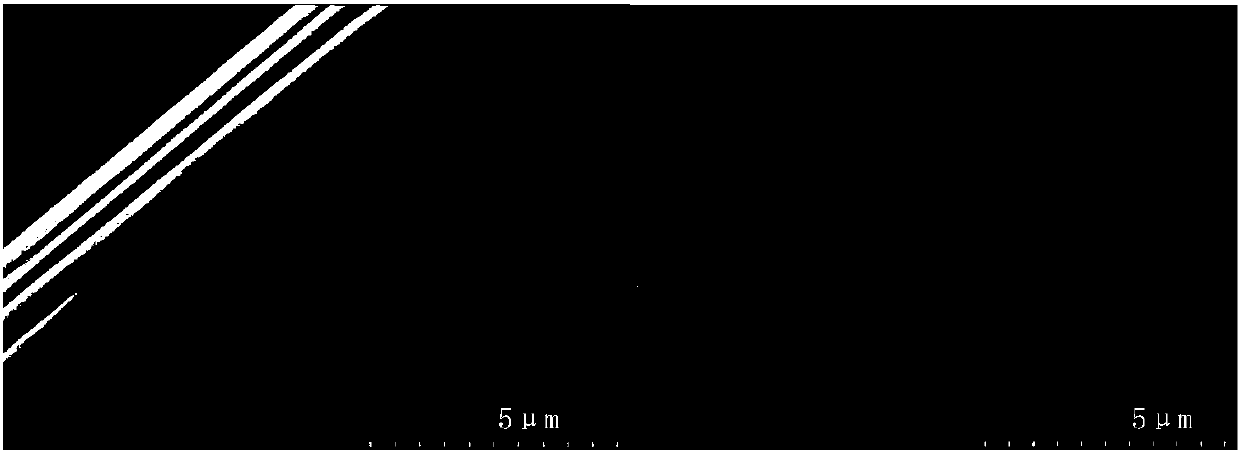

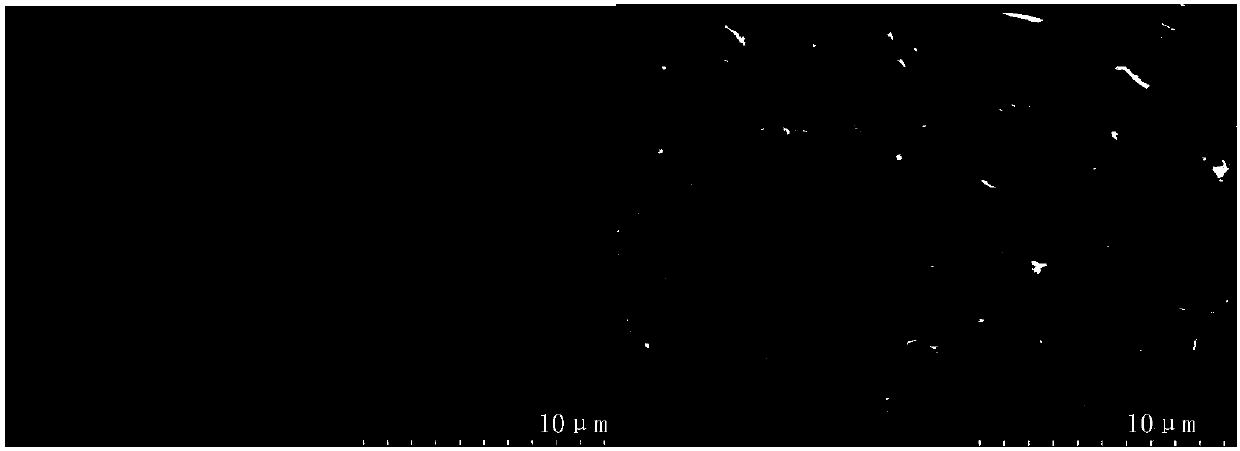

[0028] Graphene oxide aqueous solution is obtained by the Hummers method, and the degree of oxidation is controlled to realize that the total oxygen-containing group content of graphene oxide is at oxygen atom / carbon atom (O / C)=(1 / 2)-(1 / 10) (atom number ratio). At the same time, ultrasonic dispersion is used to control the number of dispersion layers of the graphene oxide in the acetone solvent to be between 1 and 10 layers. The graphene oxide aqueous solution was suction filtered to remove water, then directly dissolved in the acetone solution, and the precipitate was removed by low-speed centrifugation to obtain the graphene oxide acetone solution as the upper liquid. Control the concentration of the graphene oxide acetone solution to be 6-8 mg / mL.

[0029] 100g epoxy resin is dissolved in 50g acetone solution, and the quality of acetone is 50% of epoxy resin. Under ultrasonic conditions, 30 mL of the graphene oxide acetone solution was added to 150 g of epoxy resin in ace...

Embodiment 2

[0032] Graphene oxide aqueous solution is obtained by the Hummers method, and the degree of oxidation is controlled to realize that the total oxygen-containing group content of graphene oxide is at oxygen atom / carbon atom (O / C)=(1 / 2)-(1 / 10) (atom number ratio). At the same time, ultrasonic dispersion is used to control the number of dispersion layers of the graphene oxide in the acetone solvent to be between 1 and 10 layers. The graphene oxide aqueous solution was suction filtered to remove water, then directly dissolved in the acetone solution, and the precipitate was removed by low-speed centrifugation to obtain the graphene oxide acetone solution as the upper liquid. Control the concentration of the graphene oxide acetone solution to be 6-8 mg / mL.

[0033] 100g epoxy resin is dissolved in 100g acetone solution, and the quality of acetone is 100% of epoxy resin. Under ultrasonic conditions, 125mL of the graphene oxide acetone solution was added to 200g epoxy resin acetone ...

Embodiment 3

[0036]Prepare the graphene oxide aqueous solution by the Hummers method, control the degree of oxidation, and realize that the total content of oxygen-containing groups in graphene oxide is at oxygen atom / carbon atom (O / C)=1 / 2-1 / 10 (atom number ratio) between. At the same time, ultrasonic dispersion is used to control the number of dispersion layers of the graphene oxide in the acetone solvent to be between 1 and 10 layers. The graphene oxide aqueous solution was suction filtered to remove water, then directly dissolved in the acetone solution, and the precipitate was removed by low-speed centrifugation to obtain the graphene oxide acetone solution as the upper liquid. Control the concentration of the graphene oxide acetone solution to be 6-8 mg / mL.

[0037] 100g epoxy resin is dissolved in 150g acetone solution, and the quality of acetone is 150% of epoxy resin. Under ultrasonic conditions, 375mL of the graphene oxide acetone solution was added to 250g epoxy resin acetone s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com