Weather-proof migration-proof long-acting type microcapsule essence and preparation method thereof

A microcapsule fragrance and migration-resistant technology, which is applied in the direction of microcapsule preparation, microsphere preparation, essential oil/fragrance, etc., can solve the problems of poor compatibility between shell materials and substrates, poor weather resistance and air tightness, and decreased mechanical properties, etc. Problems, achieve the effect of reducing surface electrostatic repulsion, improving heat resistance, and high utilization of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

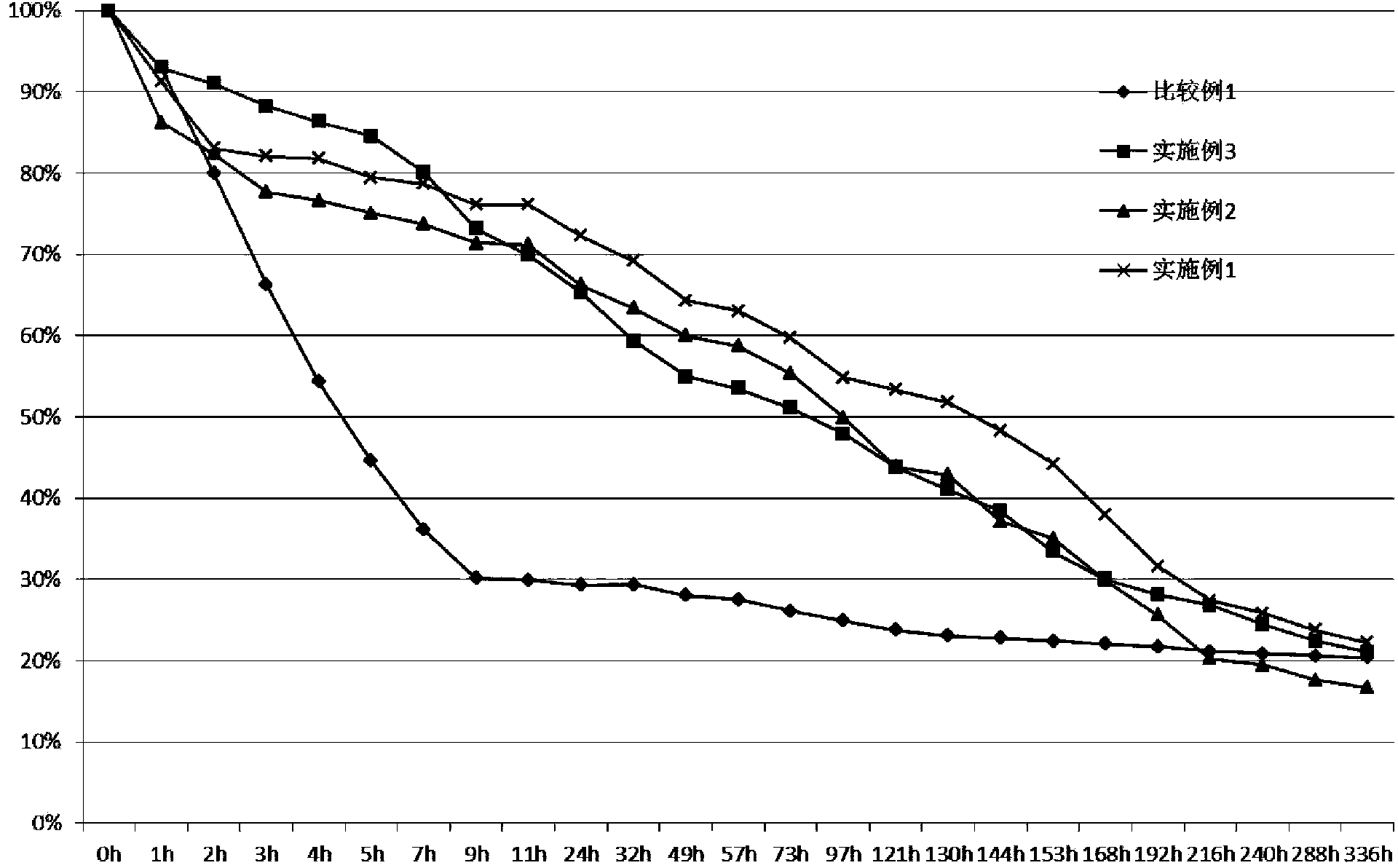

Examples

Embodiment 1

[0053] 1. Prepolymerization

[0054] Add 5.0g of melamine, 9.0g of 37% formaldehyde solution in mass concentration, 0.8g of 50% succinic dialdehyde solution in mass concentration and 100.0g of water in a 500ml three-necked flask equipped with a thermometer, a stirrer and a reflux condenser. 5% sodium hydroxide solution to adjust the pH value to 9, heat up to 70°C for reaction, react until the reaction solution is clarified, and then keep warm for 0.5 hours, then add 1.0g gelatin and continue the heat preservation reaction for 0.5 hours to prepare the amino resin mixed prepolymer solution. to 50°C for later use.

[0055] 2. Emulsification and dispersion

[0056] Add 300.0g of water, 0.4g of carboxymethyl cellulose and 0.35g of gum arabic to a 500ml beaker in turn, turn on the homogeneous emulsifier (model ESR, Shanghai Specimen Model Factory), add 12.5g of lemon flavor plus strong essence (Shanghai Linpa Fragrance Co., Ltd.), emulsified and dispersed at 50°C for 20 minutes to...

Embodiment 2

[0064] 1. Prepolymerization

[0065] Add 3.0 g of melamine, 1.9 g of phenylmelamine, 8.5 g of formaldehyde solution with a mass concentration of 37%, and 1.0 g of butanediol with a mass concentration of 50% in a 500ml three-necked flask equipped with a thermometer, a stirrer and a reflux condenser. Aldehyde aqueous solution and 90.0g water, use the sodium hydroxide solution of mass concentration 5% to adjust the pH value to 9, heat up to 70°C for reaction, react until the reaction solution is clear and keep warm for 0.5 hours, then add 0.8g gelatin and continue the heat preservation reaction for 0.5 hours to prepare The amino resin mixed prepolymer solution was obtained, and the temperature was lowered to 50° C. for later use.

[0066] 2. Emulsification and dispersion

[0067] Add 280.0g of water, 0.5g of carboxymethyl cellulose and 0.4g of gum arabic to a 500ml beaker in sequence, turn on the homogeneous emulsifier (model ESR, Shanghai Specimen Model Factory), add 14g of lem...

Embodiment 3

[0076] 1. Prepolymerization

[0077] Add 4.5g of urea, 8.0g of 37% formaldehyde solution, 1.0g of 50% glutaraldehyde solution and 100.0g of water in a 500ml three-necked flask equipped with a thermometer, a stirrer and a reflux condenser. 5% sodium hydroxide solution to adjust the pH value to 9, heat up to 70°C for reaction, react until the reaction solution is clarified, and then keep warm for 0.5 hours, then add 0.8g gelatin and continue the heat preservation reaction for 0.5 hours to prepare the amino resin mixed prepolymer solution. to 50°C for later use.

[0078] 2. Emulsification and dispersion

[0079] Add 240.0g of water, 0.34g of carboxymethyl cellulose and 0.32g of gum arabic to a 500ml beaker in turn, turn on the homogeneous emulsifier (model ESR, Shanghai Specimen Model Factory), add 12.0g of lemon flavor plus strong flavor (Shanghai Linpa Fragrance Co., Ltd.), emulsified and dispersed at room temperature for 30 minutes to prepare a flavor emulsion for later use....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com