Method for enhancing properties of epoxy-resin-base fiber composite material

A technology of fiber composite materials and epoxy resin, which is applied in the field of improving the performance of epoxy resin-based fiber composite materials, can solve the problems of inability to endow composite materials with functional characteristics, unfavorable cost compression, large-scale production, low thermal conductivity, electrical conductivity, etc., to achieve The effect of good mechanical properties, low cost, and good bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

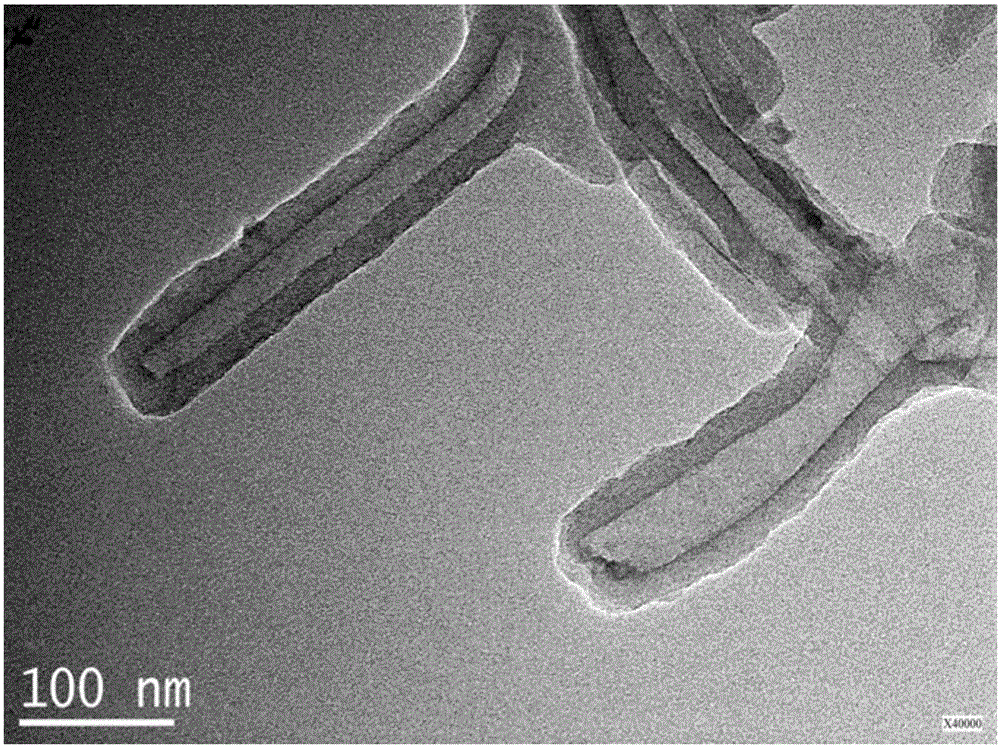

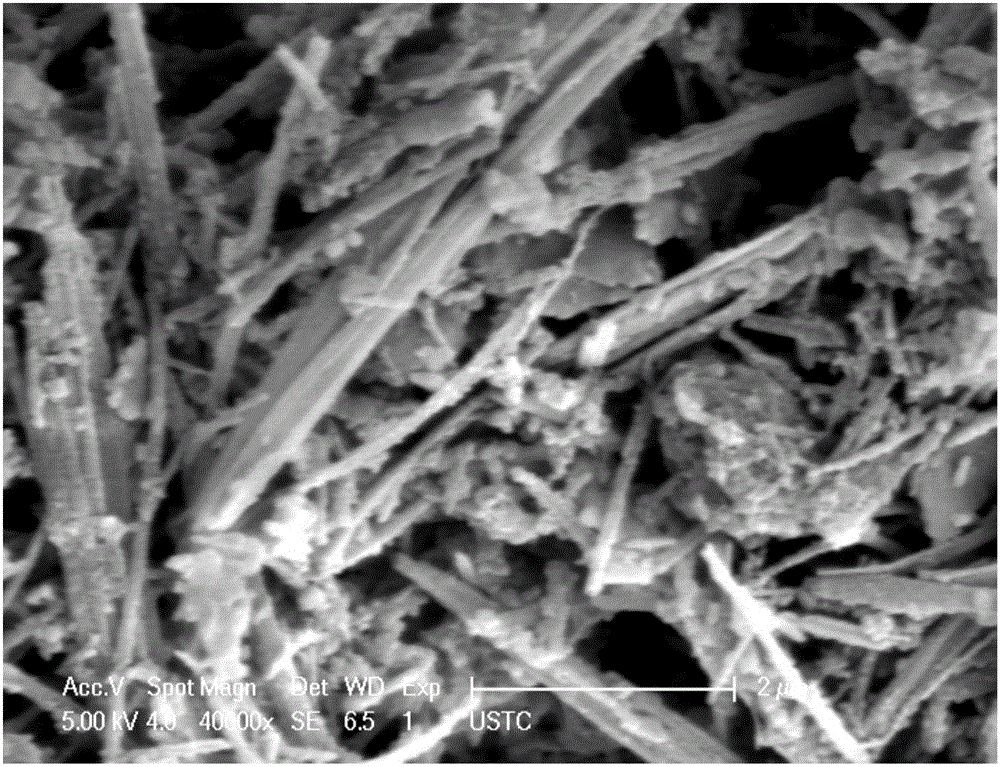

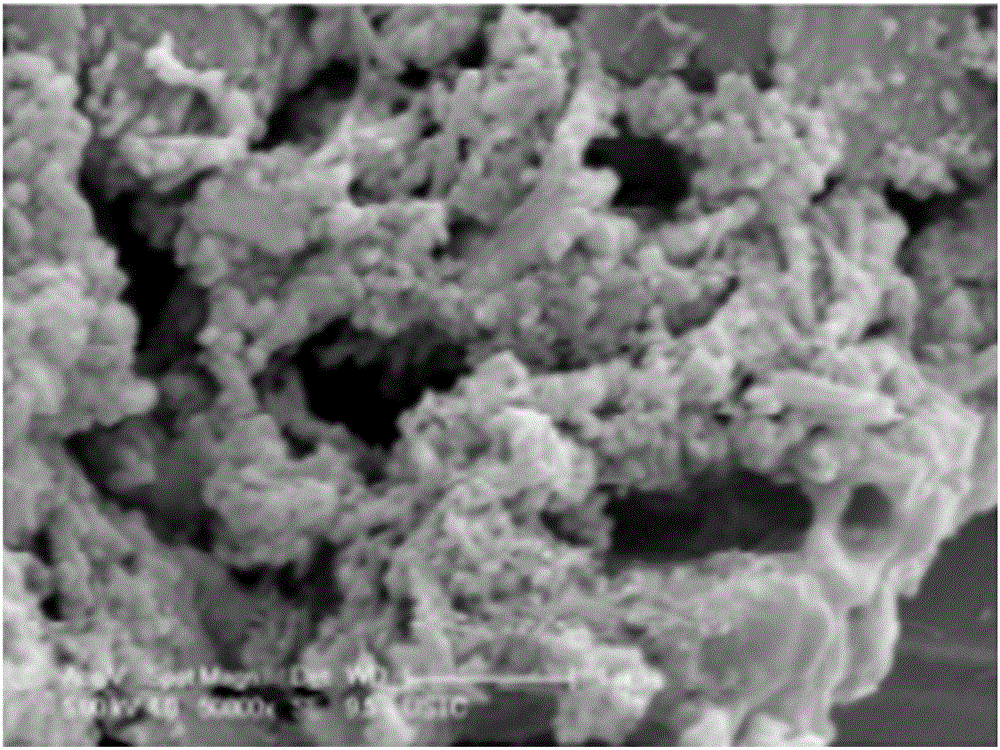

[0076] (1) Weigh 4.0 g of sieved halloysite and place it in a beaker, add 2 g of ground microcrystalline cellulose, add 80 mL of deionized water and stir magnetically for 1 hour to obtain a mixture; Catalyst ferrous ammonium sulfate hexahydrate with 0.5% mass of material, continue to stir for 10 min, then transfer to a 100 mL hydrothermal reactor, and react at 220°C for 24 h; after cooling, take out the product and wash it alternately with deionized water and ethanol until pH = 7 , dried and ground to prepare the halloysite / carbon nanocomposite material.

[0077] (2) A total of 13.87g of epoxy resin E-51 was weighed, placed in an oven and heated at 70°C; the addition ratio was 3wt% (accounting for the ratio of halloysite / carbon nanocomposite material and epoxy resin, curing agent mass sum ) halloysite / carbon nanocomposite material was dispersed in 10mL of acetone, then added to the epoxy resin matrix, stirred for 24 hours and then placed in a vacuum drying oven to remove aceto...

Embodiment 2

[0082] (1) Weigh 4.0 g of sieved halloysite and place it in a beaker, add 2 g of ground microcrystalline cellulose, add 80 mL of deionized water and stir magnetically for 1 hour to obtain a mixture; Catalyst ferrous ammonium sulfate hexahydrate with 0.5% mass of material, continue to stir for 10 min, then transfer to a 100 mL hydrothermal reactor, and react at 220°C for 24 h; after cooling, take out the product and wash it alternately with deionized water and ethanol until pH = 7 , dried and ground to prepare the halloysite / carbon nanocomposite material.

[0083] (2) Weigh 14.85g of epoxy resin E-51, place it in an oven and heat it at 70°C; the addition ratio will be 3wt% (accounting for the ratio of halloysite / carbon nanocomposite material and epoxy resin, curing agent mass sum ) halloysite / carbon nanocomposite material was dispersed in 10mL of acetone, then added to the epoxy resin matrix, stirred for 24 hours and then placed in a vacuum drying oven to remove acetone by vacu...

Embodiment 3

[0088] (1) Weigh 4.0 g of sieved halloysite and place it in a beaker, add 2 g of ground fructose, add 80 mL of deionized water and stir magnetically for 1 hour to obtain a mixture; % catalyst ammonium ferrous sulfate hexahydrate, continue to stir for 10min, then transfer to a 100mL hydrothermal reactor, and react at 220°C for 12h; after cooling, take out the product and alternately wash it with deionized water and ethanol until pH = 7, and dry it and grinding to prepare the halloysite / carbon nanocomposite material.

[0089] (2) Weigh a total of 14.85g of epoxy resin E-51, place it in an oven and heat it at 70°C; The halloysite / carbon nanocomposite was dispersed in 10mL of acetone, then added to the epoxy resin matrix, stirred for 24 hours, then placed in a vacuum oven to remove the acetone; Add 4.01 g of methyl methane into the epoxy resin, place it again in a vacuum drying oven to evacuate, remove excess acetone and air bubbles, and obtain a coating material.

[0090] (3) C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com