Low-filling high-performance nanomontmorillonite-reinforced polypropylene composite material and preparation method thereof

A technology of nano-montmorillonite and composite materials, which is applied in the field of low-filling high-performance nano-montmorillonite reinforced polypropylene composite materials and its preparation, can solve the problems of difficulty and poor compatibility, and achieve the improvement of material strength and heat dissipation. Stability and wear resistance, effect of improving interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The low-filling high-performance nano-montmorillonite reinforced polypropylene composite material in this embodiment is composed of the following raw materials by weight:

[0037] Polypropylene 90 parts

[0038] Modified montmorillonite 5 parts

[0039] 4 parts of compatibilizer maleic anhydride grafted polypropylene

[0040] Antioxidant 10760.25 parts

[0041] Antioxidant 6260.2 parts

[0042] Lubricant ethylene bis stearamide 0.4 parts

[0043] 0.5 parts of titanate;

[0044] Concrete preparation method comprises the following steps:

[0045] (1) Add 80 parts of polypropylene resin, 4 parts of compatibilizer maleic anhydride grafted polypropylene, 0.25 parts of antioxidant 1076, 0.2 parts of antioxidant 626, and 0.4 parts of lubricant ethylene bisstearamide Mix in a high-speed mixer for 2-5 minutes;

[0046] (2) Add 10 parts of polypropylene resin, 5 parts of modified montmorillonite, and 0.5 part of titanate into a high-speed mixer and mix for 2-3 minutes;

...

Embodiment 2

[0049] The low-filling high-performance nano-montmorillonite reinforced polypropylene composite material in this embodiment is composed of the following raw materials by weight:

[0050] Polypropylene 80 parts

[0051] Modified montmorillonite 8 parts

[0052] Compatibilizer maleic anhydride grafted polypropylene 10 parts

[0053] Antioxidant 10760.25 parts

[0054] Antioxidant 6260.2 parts

[0055] Lubricant ethylene bis stearamide 0.4 part

[0056] 0.5 parts of titanate;

[0057] Concrete preparation method comprises the following steps:

[0058](1) Add 70 parts of polypropylene resin, 10 parts of compatibilizer maleic anhydride grafted polypropylene, 0.25 parts of antioxidant 1076, 0.2 parts of antioxidant 626, and 0.4 parts of lubricant ethylene bisstearamide Mix in a high-speed mixer for 2-5 minutes;

[0059] (2) Add 10 parts of polypropylene resin, 8 parts of modified montmorillonite, and 0.5 parts of titanate into a high-speed mixer and mix for 2-3 minutes;

[0...

Embodiment 3

[0062] The low-filling high-performance nano-montmorillonite reinforced polypropylene composite material in this example is composed of the following raw materials by weight:

[0063] Polypropylene 85 parts

[0064] Modified montmorillonite 6 parts

[0065] 8 parts of compatibilizer maleic anhydride grafted polypropylene

[0066] Antioxidant 10760.25 parts

[0067] Antioxidant 6260.2 parts

[0068] Lubricant ethylene bis stearamide 0.4 parts

[0069] 0.5 parts of titanate;

[0070] Concrete preparation method comprises the following steps:

[0071] (1) Add 75 parts of polypropylene resin, 8 parts of compatibilizer maleic anhydride grafted polypropylene, 0.25 parts of antioxidant 1076, 0.2 parts of antioxidant 626, and 0.4 parts of lubricant ethylene bisstearamide Mix in a high-speed mixer for 2-5 minutes;

[0072] (2) Add 10 parts of polypropylene resin, 6 parts of modified montmorillonite, and 0.5 part of titanate into a high-speed mixer and mix for 2-3 minutes;

[00...

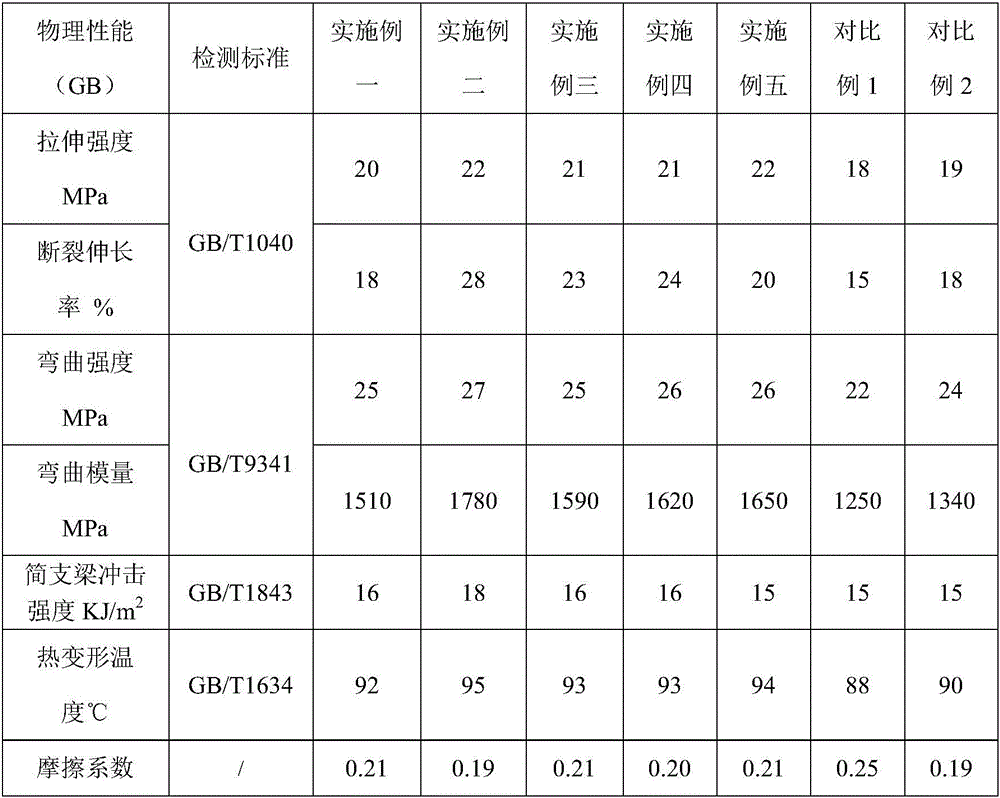

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com