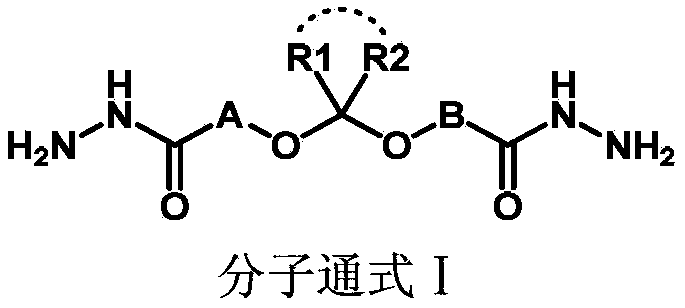

Degradable hydrazide latent epoxy resin curing agent and application thereof

An epoxy resin curing, latent technology, applied in the preparation of hydrazide, organic chemistry, chemical recycling, etc., can solve the problems of not representing recycling, occupying land, performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

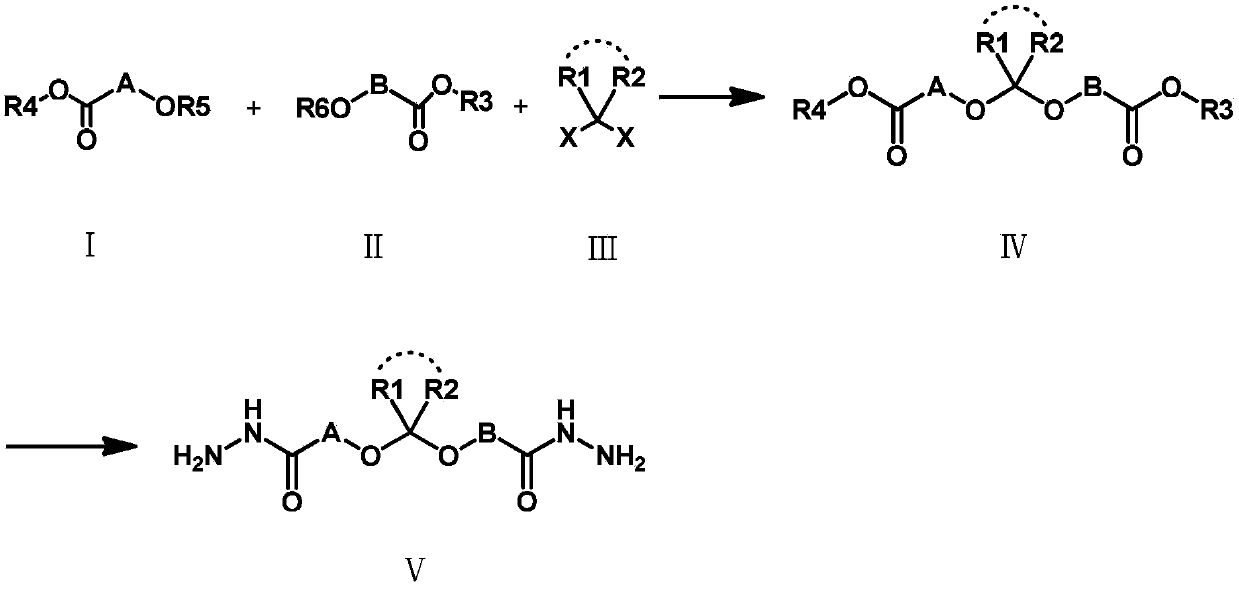

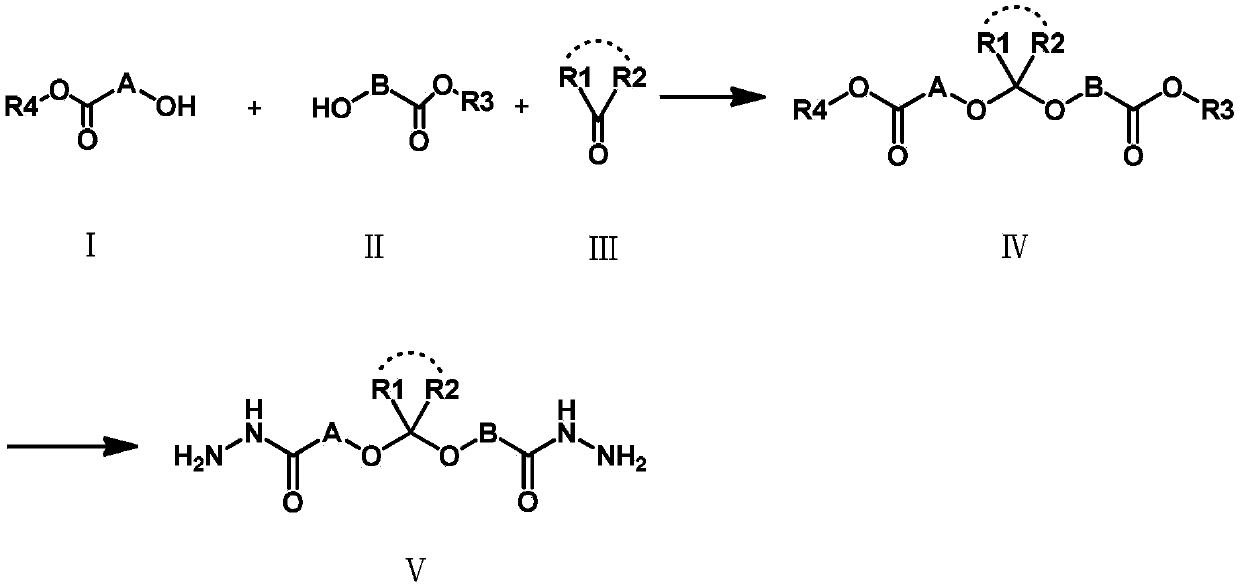

Method used

Image

Examples

Embodiment 1

[0110] Embodiment 1: the preparation of curing agent I

[0111]

[0112] In a 250-ml three-neck round-bottomed flask equipped with a condenser, dissolve 10 g of methylparaben, 6.8 g of dibromomethane, and 3.9 g of sodium hydroxide in 25 ml of N,N-dimethylformamide (DMF ), heated and refluxed for 5 hours, cooled to room temperature, concentrated the mother liquor, added water to precipitate the solid, filtered it with suction, and dried the solid to obtain 3 grams of the intermediate.

[0113] In a 250ml three-necked round-bottomed flask equipped with a condenser, dissolve the intermediate in 10ml of ethanol, add 1.4g of hydrazine hydrate, heat up to 78°C and reflux for 2 hours, cool to below 5°C, solids precipitate out, and filter out The solid was washed with ethanol to obtain 1.5 g of white solid product.

[0114] Melting point: 248-249°C

[0115] 1H-NMR(400MHz,d6-DMSO):9.66(s,2H),7.81(d,4H),7.14(d,4H),5.96(s,2H),4.45(s,4H);

[0116] LC / MS (M+H + ):317.

Embodiment 2

[0117] Embodiment 2: the preparation of curing agent II

[0118]

[0119] In a 250 milliliter three-neck round bottom flask equipped with a condenser, 10 gram of methyl salicylate, 6.8 gram of dibromomethane and 3.9 gram of sodium hydroxide were dissolved in 25 milliliters of DMF, and after reflux for 5 hours, the temperature dropped to At room temperature, the mother liquor was concentrated, and the solid was precipitated by adding water, and the solid was filtered and dried to obtain 3 g of the intermediate.

[0120] In a 250ml three-necked round-bottomed flask equipped with a condenser, dissolve the intermediate in 10ml of ethanol, add 1.4g of hydrazine hydrate, heat up to 78°C and reflux for 2 hours, cool to below 5°C, precipitate a solid, and filter it out The solid was washed with ethanol to obtain 1.1 g of a white solid product.

[0121] Melting point: 174-180°C

[0122] 1H-NMR(400MHz,d6-DMSO):9.32(s,2H),7.59(d,2H),7.46(t,2H),7.39(d,2H),7.12(t,2H),5.95(s, 2H), 4.49(...

Embodiment 3

[0124] Embodiment 3: the preparation of curing agent III

[0125]

[0126] Put 300 grams of toluene, 150 grams of ethyl lactate, 20 grams of paraformaldehyde and 2.2 grams of p-toluenesulfonic acid into a 500 milliliter three-necked round-bottom reaction flask equipped with a water separator, heat up and stir to reflux, and divide the water for 7 hours , the reaction solution was washed 8 times with 100 ml of saturated brine, the organic phase was concentrated, the residue was distilled under reduced pressure, and the fraction before 60° C. was evaporated to obtain 90 g of a residue.

[0127] Dissolve the residue with ethanol, then add 86 g of 85% hydrazine hydrate, heat and reflux for 4 hours, cool, and concentrate the solution under reduced pressure to obtain an oil, freeze, crystallize, filter, wash with ethanol until the filtrate is colorless, and dry to obtain 15 g White solid product.

[0128] Melting point: 138-139°C

[0129] 1H-NMR (400MHz, d6-DMSO): 9.1 (s, 2H), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com