Preparation method of shale micro/nano particle plugging agent for water-base drilling fluids

A technology of micro-nano particles and water-based drilling fluid, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems that cannot meet the special plugging requirements of shale gas formations, configuration cost and environmental protection, and pore throat size Low permeability and other issues, to achieve good monodispersity and water resistance, clean surface, retard pressure transmission and filtrate intrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of shale micro-nano particle plugging agent for drilling fluid: add 200mL of distilled water to a reaction kettle equipped with a stirrer, a thermometer and a heating device, and add 100mL of acetone and 12.3g of methyl methacrylate while stirring , 9.6g of styrene, 1500r / min high-speed stirring to form a stable dispersion system, heated in a water bath to a temperature of 70°C, added 0.08g of potassium persulfate, reacted for 2.5h, and naturally cooled to obtain a shale micro-nano particle plugging agent for drilling fluid .

Embodiment 2

[0032] A preparation method of shale micro-nano particle plugging agent for drilling fluid: add 300mL of distilled water to a reaction kettle equipped with a stirrer, a thermometer and a heating device, add acetone 150mL, n-butyl acrylate 16.7g, Vinyl acetate 11.2g, stirred at 1000r / min high speed to form a stable dispersion system, heated in a water bath to a temperature of 85°C, added 0.12g of azobisisoheptanonitrile, reacted for 3.5h, cooled naturally to obtain shale micro-nano particles for drilling fluid plugging agent.

Embodiment 3

[0034] A preparation method of shale micro-nano particle plugging agent for drilling fluid: add 250mL of distilled water to a reaction kettle equipped with a stirrer, a thermometer and a heating device, and add 130mL of isopropanol and ethyl methacrylate while stirring 12.3g, styrene 9.6g, 2000r / min high-speed stirring to form a stable dispersion system, heated in a water bath to a temperature of 90°C, added 0.10g of azobisisobutyronitrile, reacted for 2.0h, and naturally cooled to obtain shale microbeads for drilling fluids. Nanoparticle blocking agent.

[0035] The product performance and application effects of the embodiments are described below.

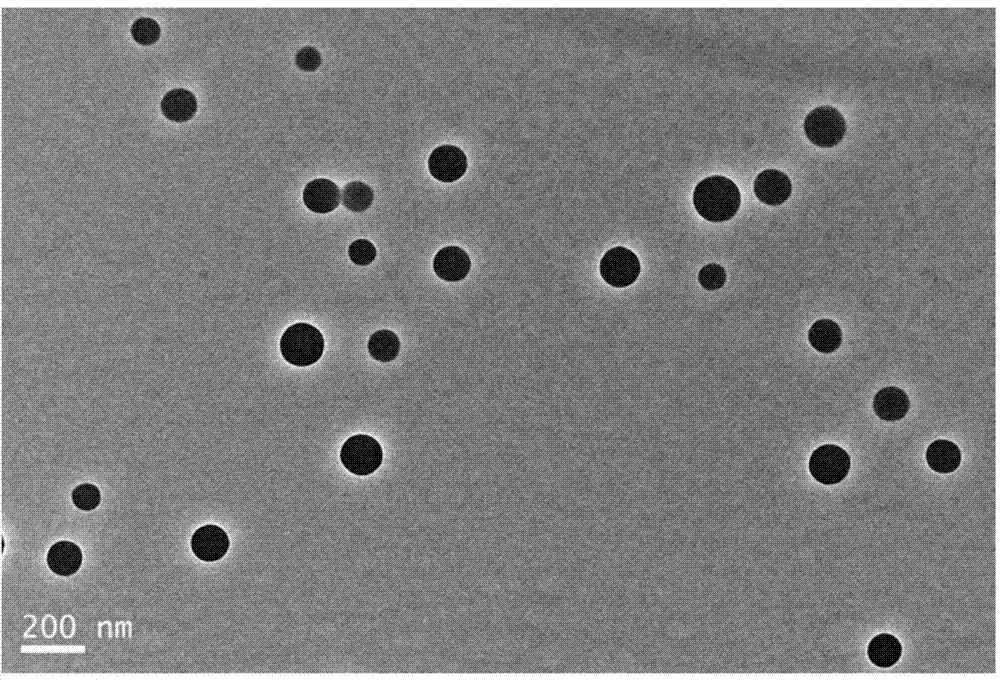

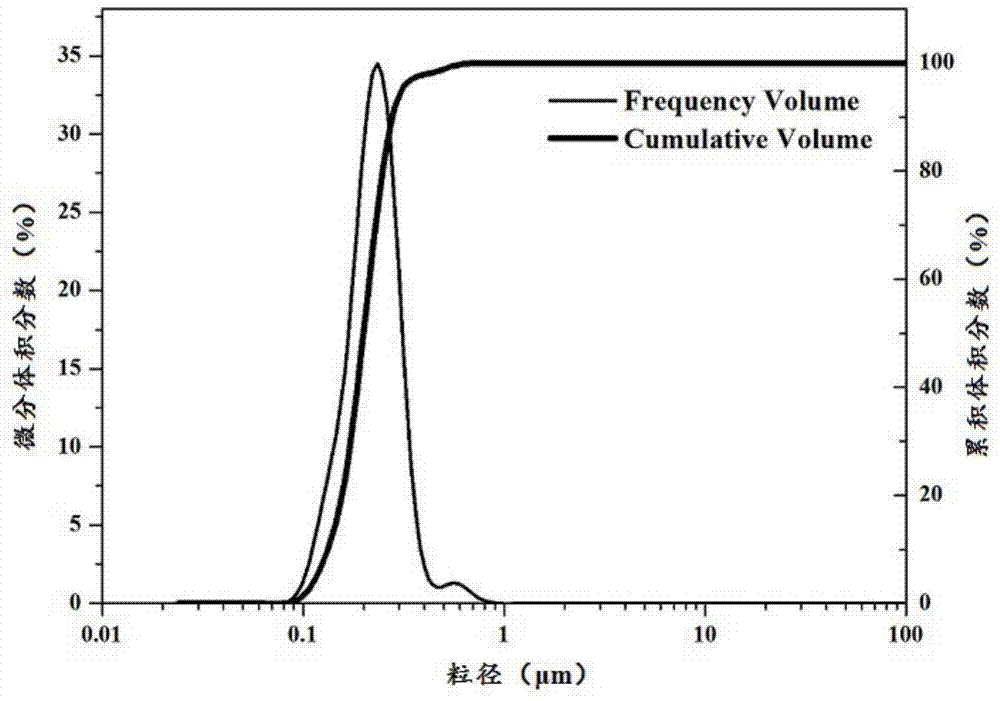

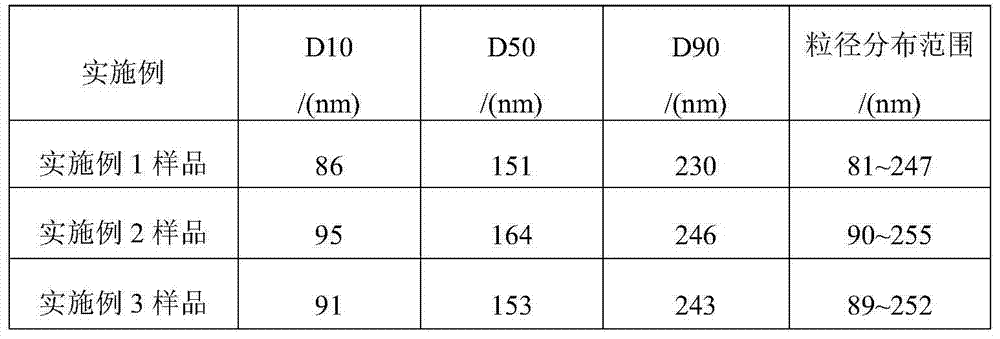

[0036] 1. Particle size distribution characteristics of shale micro-nanoparticle plugging agent

[0037] Using a laser particle size distribution tester, the particle size distribution characteristics of the micro-nanoparticle plugging agents of the above-mentioned different embodiments were tested.

[0038] It can be seen from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com