Nano spray plating technique for silver mirror

A nanometer and silver mirror technology, applied in the field of surface treatment, can solve the problems of increasing environmental protection and health requirements, threats to human health and safety, and lack of energy, and achieve the effects of wide application range, low cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

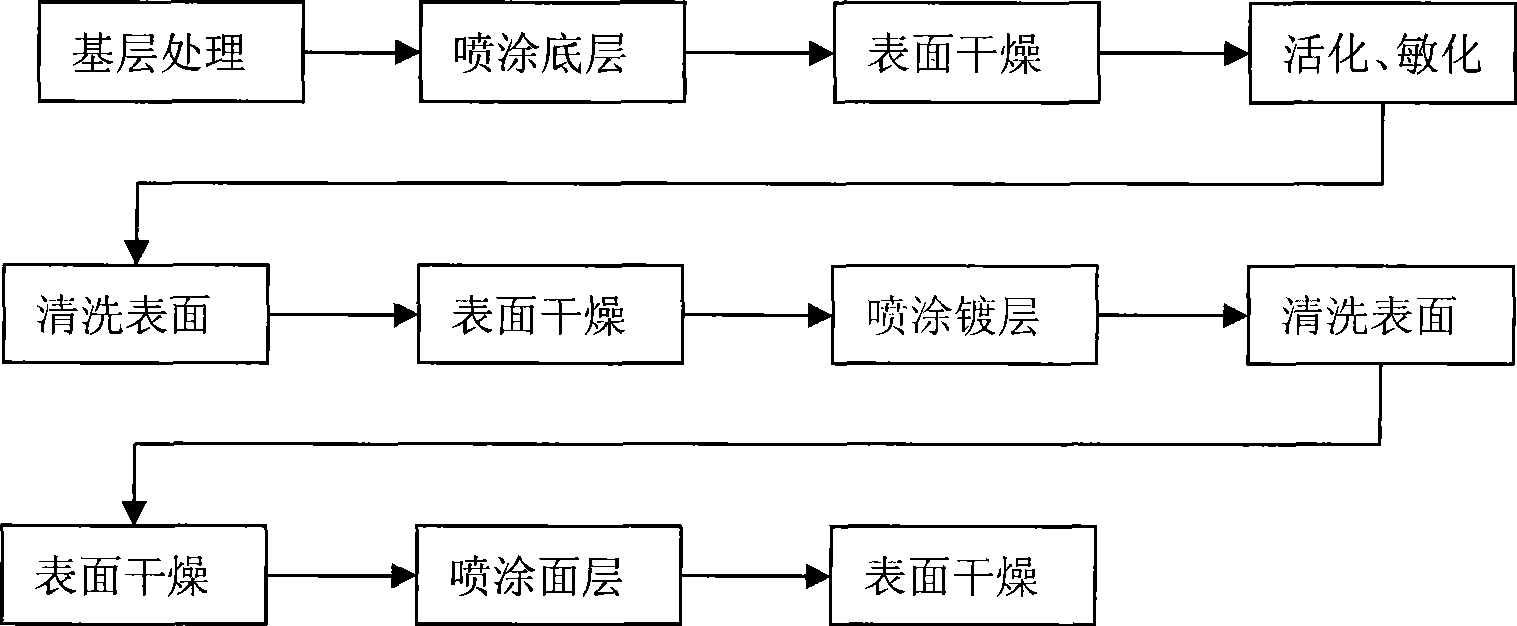

[0054] Silver mirror nano-plating of the present invention implements steps as follows for metal material:

[0055] 1), surface pretreatment

[0056] Remove dust, grease, remove oxides. Wash it with water until the water film is continuous, and blow or dry it with compressed air.

[0057] 2) Spray the primer

[0058] Spray the acrylic acid epoxy mixture synthetic resin paint, use a commercially available spray gun for construction, and the film thickness is 10-20 microns. Drying: temperature: 90-120°C, time: 20-30min.

[0059] 3), spray metal reflective layer (spray coating)

[0060] The steps are:

[0061] a), activation, sensitization treatment

[0062] Spray the activation and sensitization solution on the surface of the workpiece that has been sprayed with the primer, so that the surface of the workpiece is completely wet, and then rinse it with pure water; Based on the improved one-step treatment process, the composition of the activation and sensitization solution...

Embodiment 2

[0078] Silver mirror nano-spray plating of the present invention is as follows for non-metallic material implementation steps:

[0079] 1), surface pretreatment

[0080] Remove dust, grease. Wash it with water until the water film is continuous, and blow or dry it with compressed air.

[0081] 2) Spray the primer

[0082] Spray the acrylic acid epoxy mixture synthetic resin paint, use a commercially available spray gun for construction, and the film thickness is 10-20 microns.

[0083] 3), spray metal reflective layer (spray coating)

[0084] The steps are:

[0085] a), activation, sensitization treatment

[0086] Spray the activation and sensitization solution on the surface of the workpiece that has been sprayed with the primer, so that the surface of the workpiece is completely wet, and then rinse it with pure water; Based on the improved one-step treatment process, the composition of the activation and sensitization solution:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com