Automatic taking-up and roll changing device

An automatic, reeling technology, applied in the direction of winding strips, transportation and packaging, thin material handling, etc., can solve the problems of the reeling reel not being able to absorb sheets, unsafe use, poor reliability, etc., to achieve convenient automatic and fast loading. Volume, low production cost, the effect of reducing the process and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

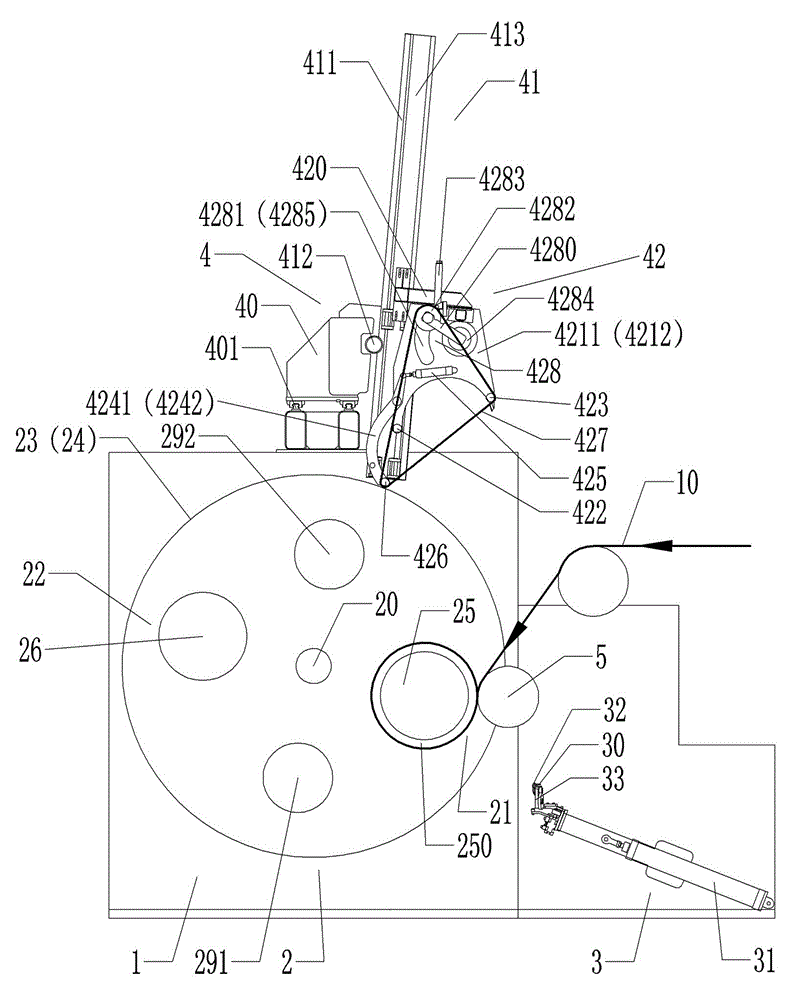

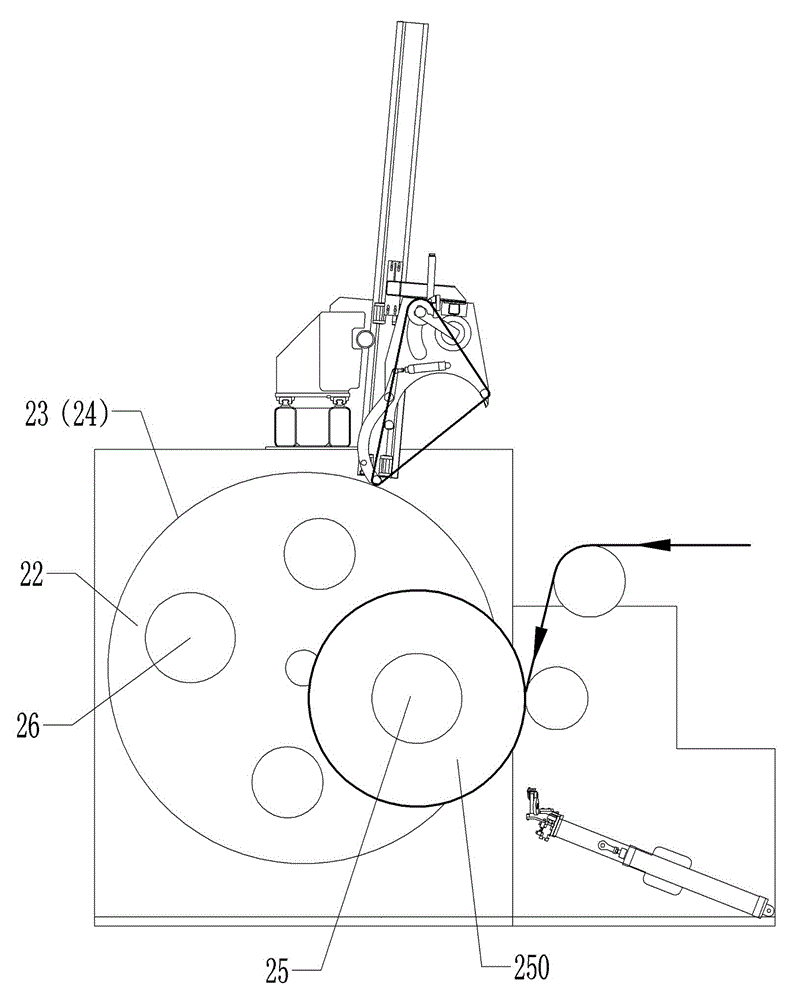

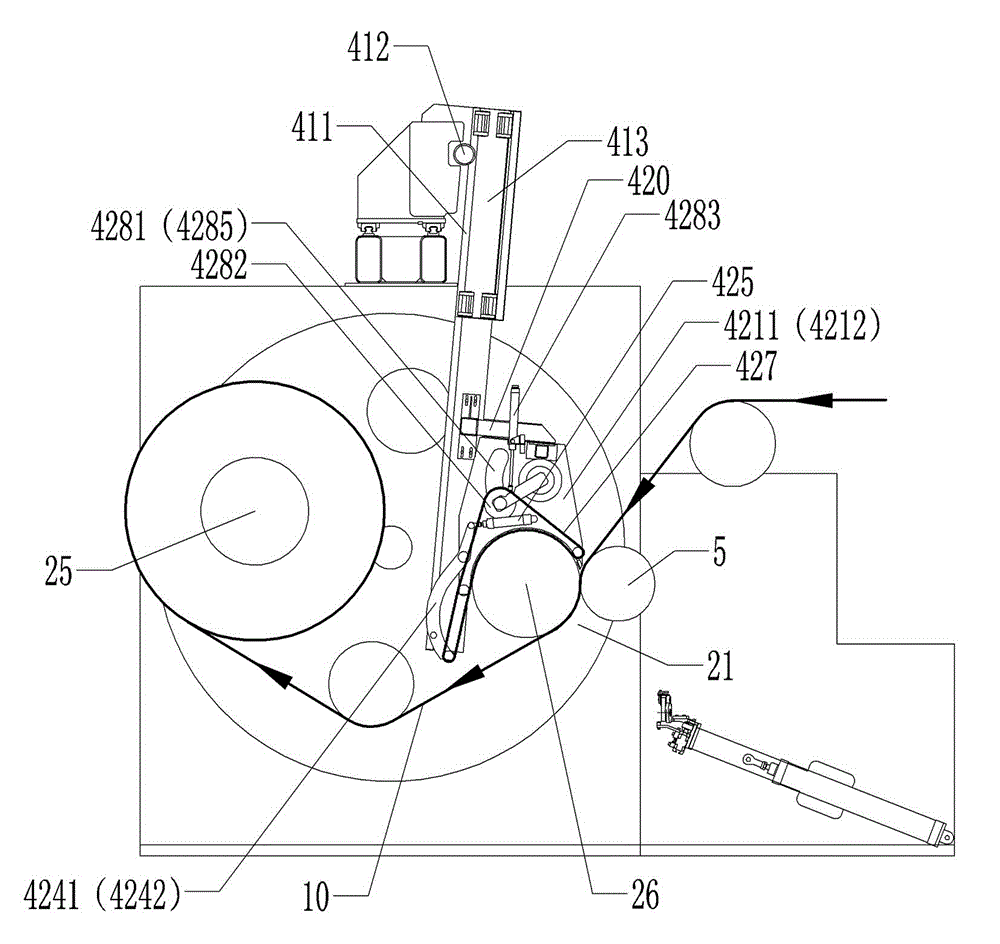

[0106] Such as Figure 1 to Figure 12 As shown, the automatic rewinding and rewinding device in this preferred embodiment includes a frame 1, a double-station rewinding mechanism 2 and an automatic rewinding mechanism, and the above-mentioned automatic rewinding mechanism includes a cutter mechanism 3 and an automatic winding mechanism, The above-mentioned automatic winding mechanism includes an arc-shaped winding mechanism 4 and a pressure roller 5 .

[0107] In this preferred embodiment, an arc-shaped winding mechanism 4 is provided on the frame 1 at one end of the above-mentioned double-station winding mechanism 2. Obviously, when the sheet 10 is a wide sheet, it can An arc-shaped winding mechanism 4 is respectively provided on the frame 1 at the two ends of the station winding mechanism 2;

[0108] The above-mentioned cutter mechanism 3 and the arc-shaped winding mechanism 4 are all located outside the double-station winding mechanism 2, and the cutting knife mechanism 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com