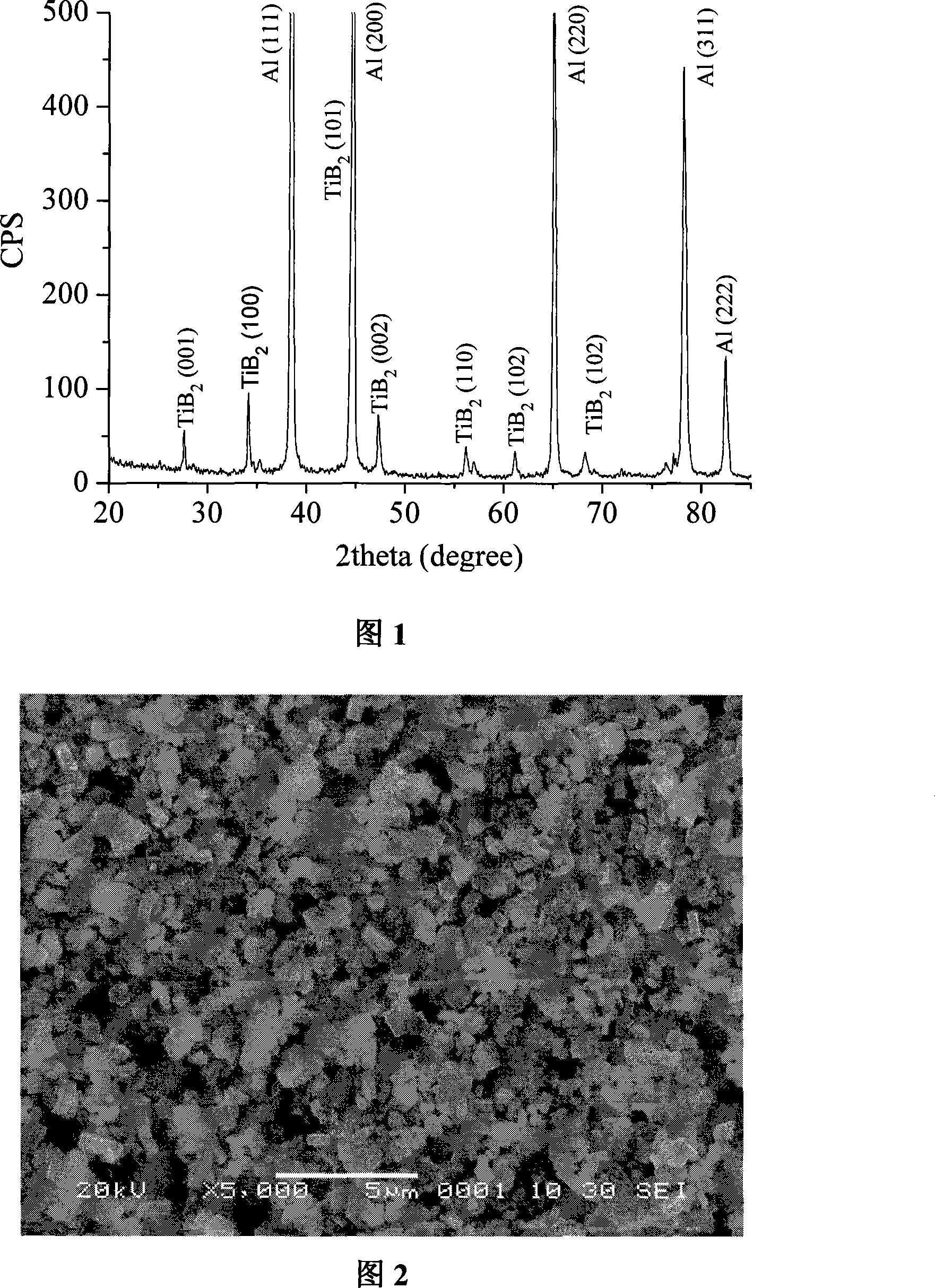

Endogenesis sub-micron TiB2 particle enhanced aluminum-base composite material and preparing technique thereof

A particle-reinforced aluminum and composite material technology, applied in the field of metal matrix composite materials, can solve the problems of inability to meet the requirements of industrial scale production, poor wettability between reinforced particles and the matrix, and high price of reinforced particles, and achieve great potential in market application. The effect of easy control of volume content and easy control of volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Composition of material: Zn 8.0wt%, Mg 1.3wt%, Cu 3.5wt%, Zr 0.2wt%, TiB 2 The particle content is 10wt%, and the rest is Al.

[0036] After adding pure aluminum ingots into the smelting furnace, the furnace temperature is set at 750°C. After it is completely melted, the temperature is raised to 860-900°C. After the aluminum melt is kept at 860-900°C, add CH-T type at 860-900°C. Cover the melt with a sodium-free covering agent, dry NaBF4 and Al-Ti with a mass ratio of 1:2, add it to the melt, and stir. During the stirring process, use argon inert gas protection, and the stirring speed is 300r / min , the stirring time is 60min, and the stirring temperature is 860-900°C; after the reaction is completed, remove the reaction by-products, add pure Zn, pure magnesium Al-Cu, Al-Zr, and add a refining agent to the melt after melting for degassing and refining. The refining agent adopts the green environmental protection ZS-AZ refining agent, the refining temperature is 750 °C, ...

Embodiment 2

[0038] Composition of material: Zn 4.5wt%, Mg 3.0wt%, Cu 1.0wt%, Zr 0.05wt%, TiB 2 The particle content is 20wt%, and the rest is Al.

[0039] After adding pure aluminum ingots into the smelting furnace, the furnace temperature is set at 750°C. After complete melting, the temperature is raised to 660-860°C. After the aluminum melt is kept at 660-860°C, CH-T is added at 750-860°C. Type sodium-free covering agent to cover the melt, dry KBF4 and Al-Ti with a mass ratio of 1:2.5, add it to the melt, and stir it. During the stirring process, protect it with argon inert gas, and the stirring speed is 2000r / min , the stirring time is 30min, and the stirring temperature is 750-860°C; after the reaction is completed, remove the reaction by-products, add pure Zn, pure magnesium Al-Cu, Al-Zr, and add a refining agent to the melt after melting for degassing and refining. The refining agent adopts the green environmental protection ZS-AZ refining agent, the refining temperature is 720°C, ...

Embodiment 3

[0041] Composition of material: Zn 10wt%, Mg 2.5wt%, Cu 5.0wt%, Zr 0.25wt%, TiB 2 The particle content is 15wt%, and the rest is Al.

[0042] After adding pure aluminum ingots into the smelting furnace, the furnace temperature is set at 750°C. After it is completely melted, the temperature is raised to 700-900°C. After the aluminum melt is kept at 700-900°C, CH-T is added at 750-900°C. Type sodium-free covering agent to cover the melt, dry the NaBF4 and Al-Ti with a mass ratio of 1:2, add it to the melt, stir, and protect it with argon inert gas during the stirring process, and the stirring speed is 1000r / min , the stirring time is 50min, and the stirring temperature is 750-900°C; after the reaction is completed, remove the reaction by-products, add pure Zn, pure magnesium Al-Cu, Al-Zr, and add a refining agent to the melt for degassing and refining after melting. The refining agent adopts the green environmental ZS-AZ refining agent, the refining temperature is 740°C, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com