A titanium alloy with medium strength and high impact toughness for marine engineering

A technology of impact toughness and marine engineering, which is applied in the field of titanium alloys, can solve problems such as failure to meet the performance requirements of high-pressure equipment, adverse effects on alloy performance, and low strength of industrial pure titanium, and achieve improved cold and hot processing performance, improved thermal processing performance, Effect of improving plasticity and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

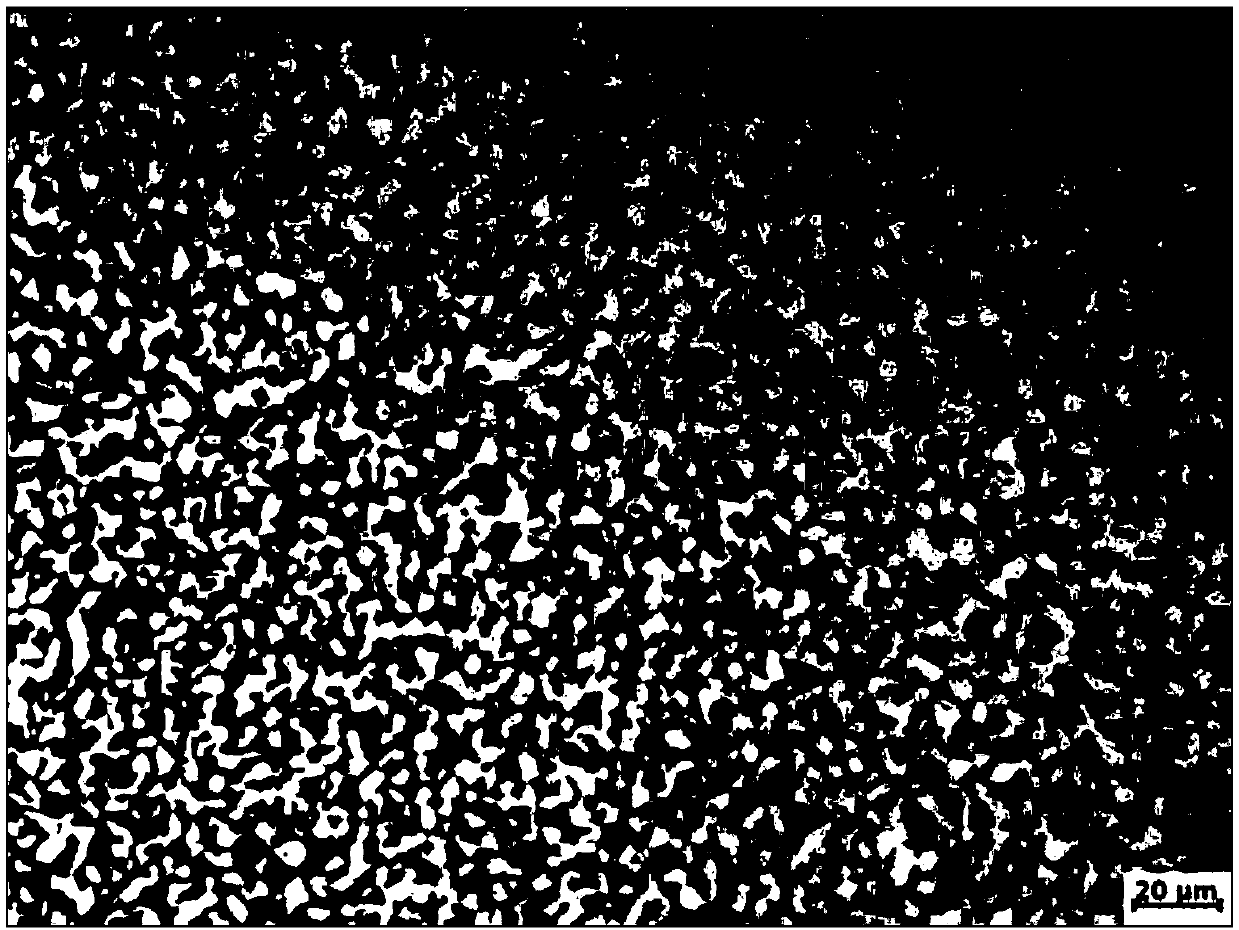

Image

Examples

Embodiment 1

[0024] The composition of the titanium alloy with medium strength and high impact toughness in this example is Ti-3.5Al-0.5Zr-1.2Mo-1.5Nb, that is: the alloy composition is Al 3.5%, Zr 0.5%, Mo 1.2%, Nb 1.5% by weight percentage %, the balance is Ti and unavoidable impurities.

[0025] The preparation process of the medium-strength and high-impact-toughness titanium alloy in this example is as follows: use Al-Mo master alloy, Al-Nb master alloy, aluminum beans, sponge zirconium and sponge titanium according to the design composition, and press the electrode, and then in the vacuum self-consumption The arc furnace is smelted for 2 to 3 times, and the smelted ingot is forged three times at 1150°C, 1050°C and 950°C respectively, and then the finished product is processed at 800°C to 900°C to obtain a diameter of 20mm. of bars. After simple annealing at 800°C / 1h, the bar's mechanical properties at room temperature are: tensile strength 645MPa, yield strength 546MPa, elongation af...

Embodiment 2

[0028] The composition of the titanium alloy with medium strength and high impact toughness in this example is Ti-1.8Al-3Zr-0.5Mo-2.5Nb, that is: the alloy composition is Al 1.8%, Zr 3.0%, Mo 0.5%, Nb 2.5% by weight percentage , the balance being Ti and unavoidable impurities.

[0029] The preparation process of the medium-strength and high-impact-toughness titanium alloy in this example is as follows: use Al-Mo master alloy, Al-Nb master alloy, aluminum beans, sponge zirconium and sponge titanium according to the design composition, and press the electrode, and then in the vacuum self-consumption The arc furnace is smelted for 2 to 3 times, and the smelted ingot is forged three times at 1150°C, 1050°C and 950°C respectively, and then the finished product is processed at 800°C to 900°C to obtain a diameter of 20mm. of bars. After the bar is annealed at 800°C / 1h, AC simple annealing, its mechanical properties at room temperature are: tensile strength is 572MPa, yield strength ...

Embodiment 3

[0031] The composition of the titanium alloy with medium strength and high impact toughness in this embodiment is Ti-2Al-1Zr-0.8Mo-1Nb, that is: the alloy composition is calculated as Al 2.0%, Zr 1.0%, Mo 0.8%, Nb 1.0%, and the rest The amount is Ti and unavoidable impurities.

[0032] The preparation process of the medium-strength and high-impact-toughness titanium alloy in this example is as follows: use Al-Mo master alloy, Al-Nb master alloy, aluminum beans, sponge zirconium and sponge titanium according to the design composition, and press the electrode, and then in the vacuum self-consumption The arc furnace is smelted for 2 to 3 times, and the smelted ingot is forged three times at 1150°C, 1050°C and 950°C respectively, and then the finished product is processed at 800°C to 900°C to obtain a diameter of 20mm. of bars. After the bar is annealed at 800°C / 1h, AC simple annealing, its room temperature mechanical properties are: tensile strength is 588MPa, yield strength is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com