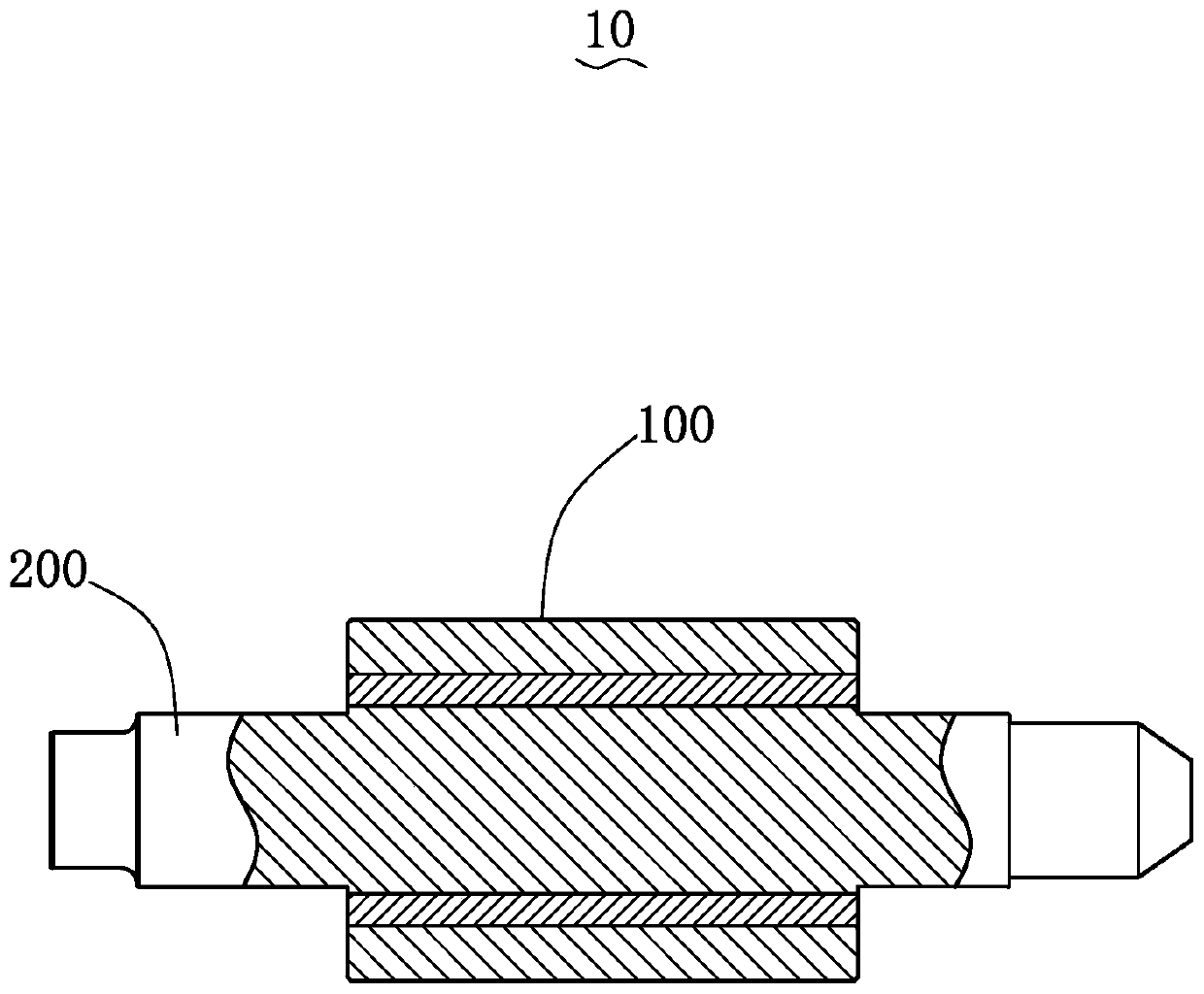

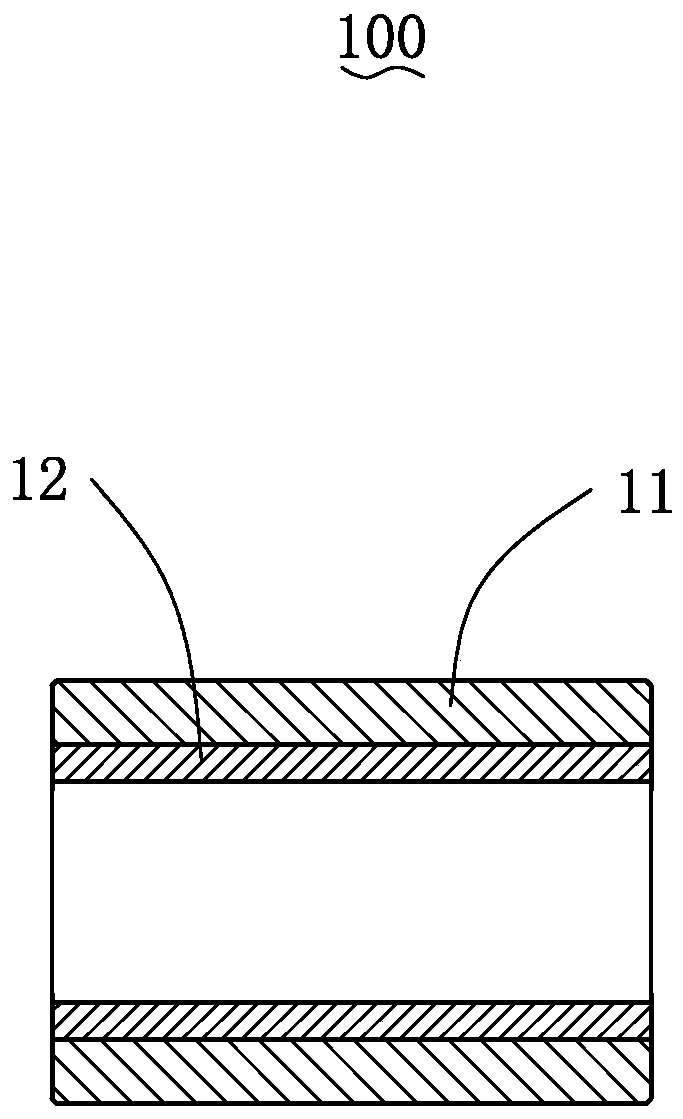

Bi-metal composite high-vanadium high-speed steel roller sleeve for hot rolling

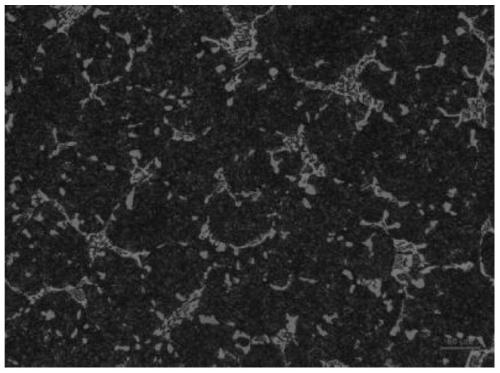

A high-speed steel and bimetal technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of poor heat treatment and segregation of the overall roll, and achieve the effect of easy segregation, uniform distribution, and difficulty in segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the double-metal composite high-vanadium high-speed steel roll sleeve 100 for hot rolling comprising the following steps:

[0057] Step S1, melting molten steel according to the chemical composition of the wear-resistant layer of the above-mentioned high-vanadium high-speed steel;

[0058] In order to improve the quality of molten steel and improve the casting state, in the present invention, preferably, an appropriate amount of additives is added to molten steel for smelting. The addition of additives, on the one hand, is beneficial to adjust and control the content of easily oxidized elements and trace elements, which can greatly increase the alloy yield, reduce smelting costs, shorten smelting time, and precisely control the composition; on the other hand, it can play a role in pure steel liquid and partially change the nature and shape of inclusions.

[0059] When the temperature of the molten steel reaches 1620°C, the calcium-aluminum cor...

Embodiment 1

[0079] In the hot-rolling dual-metal composite high-vanadium high-speed steel roll sleeve of this embodiment, the outer high-speed steel wear-resistant layer is the working layer, and its outer diameter is Ф400mm; the inner low-carbon steel is 20# seamless steel pipe, and its outer diameter is Ф270mm, wall thickness is 35mm.

[0080] In this embodiment, the preparation process of the double-metal composite high-vanadium high-speed steel roll sleeve for hot rolling includes the following steps:

[0081] In step S1, the outer layer molten steel of the composite high-vanadium high-speed steel roller sleeve is first melted in an intermediate frequency induction furnace, and its chemical composition includes the following composition by weight percentage:

[0082] C: 2.1%, Si: 0.90%, Mn: 0.58%, S≤0.03%, P≤0.04%, V: 6%, Cr: 4.8%, Mo: 3.5%, Nb: 1.0%, Co: 2.0%, W: 0.8%, the balance is Fe and unavoidable impurities;

[0083] When the temperature of the above molten steel reaches 1620...

Embodiment 2

[0094] The hot-rolling double-metal composite high-vanadium high-speed steel roll sleeve of this embodiment is basically the same as that of Embodiment 1, except that:

[0095] (1) In the present embodiment, the alloy composition of the outer layer includes the following composition by weight percentage:

[0096] C: 1.8%, Si: 0.5%, Mn: 0.3%, S≤0.03%, P≤0.04%, V: 5%, Cr: 6%, Mo: 5%, Nb: 3%, Co: 4.0%, W: 0.5%, the balance is Fe and unavoidable impurities;

[0097] (2) In this embodiment, the preheating temperature of the seamless steel pipe is 700°C, and the molten steel casting temperature is 1620°C;

[0098] (3) In the present embodiment, the annealing process is as follows: slowly raise the temperature of the double-metal composite high-vanadium high-speed steel roller sleeve to 820 ° C, keep it warm for 8 hours, and then cool it in the furnace to normal temperature and take it out of the furnace;

[0099] The quenching process is as follows: slowly raise the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com