Method for preparing copper-tungsten alloy from ultrafine tungsten powder

A technology of ultra-fine tungsten powder and copper-tungsten alloy, used in metal processing equipment, coating, transportation and packaging, etc., can solve the problem of particle size limitation of tungsten powder, the influence of hardness and wear resistance of copper-tungsten alloy, preparation time of precursor preparation shortening of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing copper-tungsten alloy by using ultrafine tungsten powder, comprising the following steps:

[0037] S1. Pretreatment of tungsten powder:

[0038] S1-1. Ball milling: clean the tungsten powder and put it into a ball mill for 8 hours, and add absolute ethanol. The weight ratio of the amount of absolute ethanol added to the tungsten powder is 1:1, and the tungsten powder with a particle size of 10-50 μm after ball milling is obtained. ;

[0039] S1-2. Atomized powder making: use high-pressure water mist to atomize the ball-milled tungsten powder to obtain ultrafine tungsten powder with a particle size of 50-350nm after atomization;

[0040]S1-3. Alkali / pickling: The atomized ultrafine tungsten powder is subjected to alkali washing and pickling respectively. The steps of alkali washing are: immerse the ultrafine tungsten powder in the degreasing agent, the degreasing agent and the ultrafine tungsten The volume ratio of the powder is 4:1, and the comp...

Embodiment 2

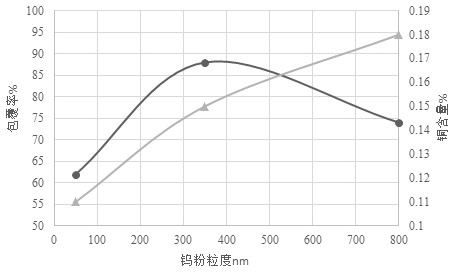

[0048] This embodiment is basically the same as Embodiment 1, except that the particle size of the tungsten powder in the pretreatment of the tungsten powder is different.

[0049] S1. Pretreatment of tungsten powder:

[0050] S1-1. Ball milling: clean the tungsten powder and put it into a ball mill for 8 hours, and then add absolute ethanol. The weight ratio of the amount of absolute ethanol added to the tungsten powder is 1:1, and the tungsten powder with a particle size of 50-80 μm after ball milling is obtained. ;

[0051] S1-2. Atomized powder making: use high-pressure water mist to atomize the ball-milled tungsten powder to obtain ultrafine tungsten powder with a particle size of 350-600nm after atomization.

Embodiment 3

[0053] This embodiment is basically the same as Embodiment 1, except that the particle size of the pre-treated tungsten powder in step S1 is different.

[0054] S1. Pretreatment of tungsten powder:

[0055] S1-1. Ball milling: Clean the tungsten powder and put it into a ball mill for 8 hours, and add absolute ethanol. The weight ratio of the amount of absolute ethanol added to the tungsten powder is 1:1, and the tungsten powder with a particle size of 80-100 μm after ball milling is obtained. ;

[0056] S1-2. Atomized powder making: use high-pressure water mist to atomize the ball-milled tungsten powder to obtain ultrafine tungsten powder with a particle size of 600-800nm after atomization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com