Method for preparing two-phase granular mixed reinforced magnesium alloy based composite material

A technology for strengthening magnesium alloys and composite materials, which is applied in the field of preparation of magnesium alloy-based composite materials, can solve the problems of composite material performance degradation, TiC hardness decrease, etc., and achieve the effect of fine particle size, uniform distribution and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare 10% (TiB 2 +TiC) / AZ91 composite material

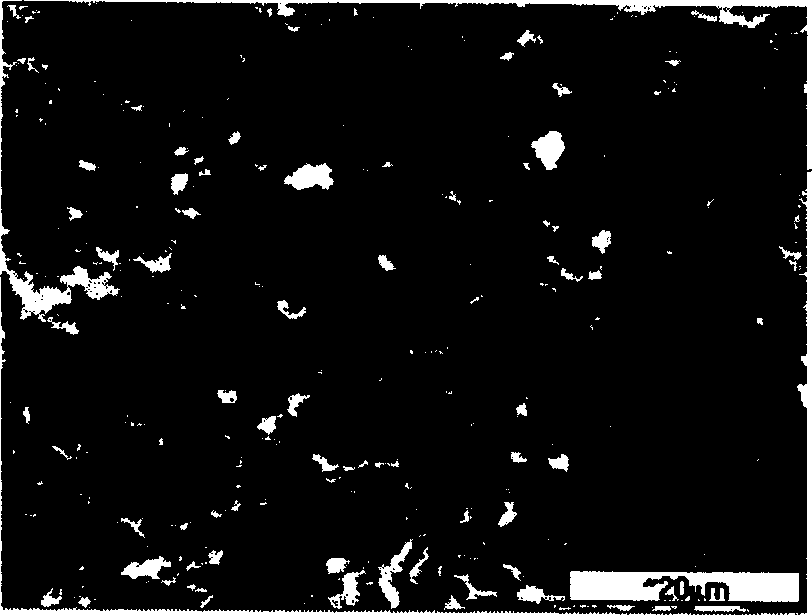

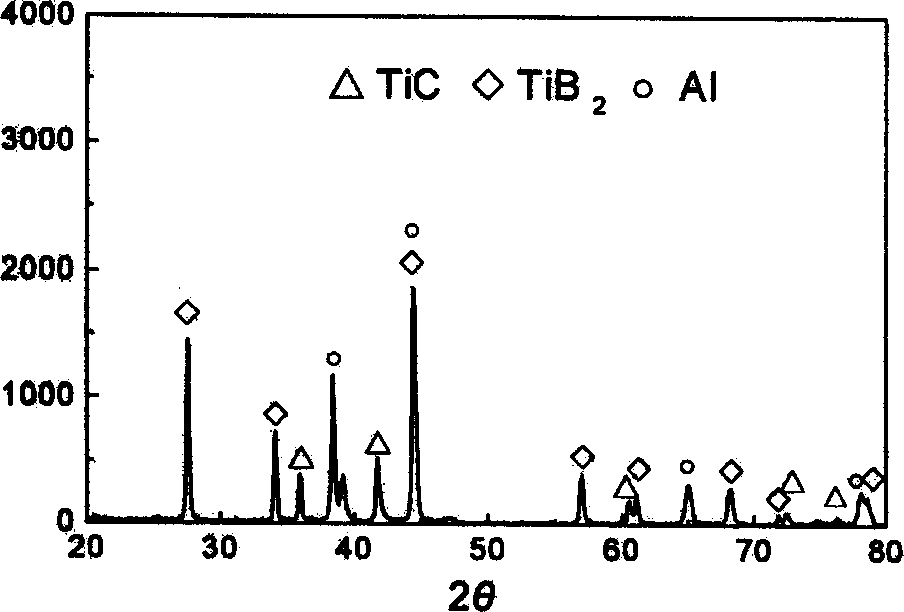

[0031] Al powder of ~29 microns, Ti powder of ~15 microns, B powder of ~3 microns and C powder of ~38 microns are taken, and AZ91 ingot, pure magnesium ingot, pure zinc, and Al-Mn master alloy are used as ingredients for the matrix magnesium alloy. The above four kinds of powders are prepared according to the ratio of Al content of 40% by weight, atomic ratio (B+C): Ti=3.0, and atomic ratio B:Ti=2, and weight ratio of B+Ti to 50%. Mix in a ball mill for 8 hours, then press on a 20-ton press to form a cylindrical reaction prefabricated block of φ55×30, and the compaction rate of the compact is 75% of the theoretical density of the mixed powder. The reaction prefabricated block was placed in a vacuum heating device, and the temperature was raised to 680 °C at a heating rate of 10 °C / min to initiate a chemical synthesis reaction, and the product was (50% TiB 2 +10%TiC) / 40%Al mesophase carrier, its microscopic scanning st...

Embodiment 2

[0033] Prepare 15% (TiC+TiB 2 ) / ZM5 composite material

[0034]Al powder of ~74 microns, Ti powder of ~25 microns, B powder of ~3 microns and C powder of ~74 microns are taken, and the matrix magnesium alloy adopts ZM5 ingot, pure magnesium ingot Al-Mn master alloy and pure zinc as ingredients. The above four kinds of powders are 60% by weight percentage of Al content, atomic ratio (B+C): Ti=3.1, and atomic ratio B:Ti=2, weight ratio B+Ti is 10%, in the drum type small ball mill Mix for 24 hours, and then press into a cylindrical reaction prefabricated block of φ55×30, and the compaction rate of the compact is 82% of the theoretical density of the mixed powder. The reaction prefabricated block was placed in a heating device protected by high-purity argon, and the temperature was raised to 765°C at a heating rate of 25°C / min to initiate a chemical synthesis reaction to obtain (30%TiC+10%TiB 2 ) / 60%Al mesophase support, and then this contains the corresponding TiC and TiB 2 T...

Embodiment 3

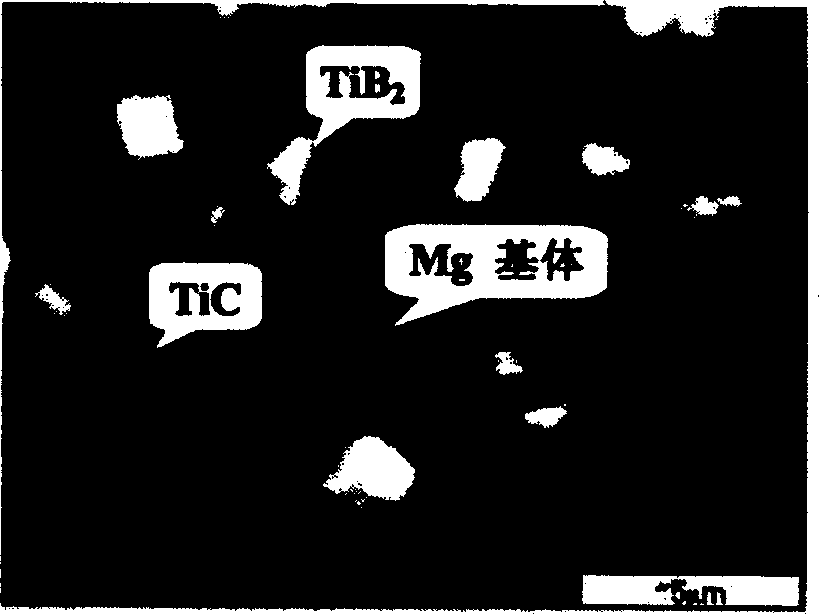

[0036] Prepare 5% (TiB 2 +TiC) / AZ91 composite material

[0037] Al powder of ~29 microns, Ti powder of ~15 microns, B powder of ~3 microns, and C powder of ~38 microns are taken, and the matrix magnesium alloy is prepared by using AZ91HP ingot, pure magnesium ingot, Al-Mn master alloy and pure zinc. The above four kinds of powders are prepared according to the ratio of Al content of 50% by weight, atomic ratio (B+C): Ti=3, and atomic ratio B:Ti=2, and weight ratio of B+Ti to 25%. Mix in a ball mill for 16 hours, then press on a 20-ton press to form a cylindrical reaction prefabricated block of φ55×30, and the compaction rate of the compact is 75% of the theoretical density of the mixed powder. The reaction prefabricated block is placed in a vacuum heating device, and the temperature is raised to 640 °C at a heating rate of 18 °C / min to initiate a chemical synthesis reaction, and the product is (25% TiB 2 +25%TiC) / 50%Al mesophase support, its microscopic scanning structure an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com