Blowing purifying method for casting ladle

A gas purification and ladle technology, applied in foundry equipment, casting melt containers, manufacturing tools, etc., can solve the problem of short service life of steel (iron) water ladle, inability to purify steel (iron) water, poor homogenization of alloy composition, etc. problem, to achieve the effect of being conducive to removal, not easy to segregate, and promoting the growth of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: In the Foundry Research Institute of Foundry Co., Ltd. of China First Automobile Group Corporation, a 300kg pouring ladle is used to blow argon into the hot forging mold steel molten steel in the ladle through the vent plug installed in the air blowing device at the bottom of the ladle , to carry out molten steel purification treatment.

[0016] Argon blowing pressure (relative pressure): 0.11PMa

[0017] Argon blowing flow rate: 15L / min.

[0018] Molten steel temperature when blowing air: 1680°C

[0019] Argon blowing time: 3.5min.

[0020] Stand still after blowing argon: 1min.

[0021] Compared with unpurified air blowing purification, the S content is reduced by 50% on average, the P content is reduced by 30% on average, and the H and O content are reduced by 30%.

Embodiment 2

[0022] Embodiment 2: In the steel casting workshop of a foundry of China First Automobile Group Corporation Casting Co., Ltd., a 3t pouring ladle is used to blow the hot forging mold steel molten steel into the ladle through the vent plug installed in the air blowing device at the bottom of the ladle. Argon gas is used to purify molten steel.

[0023] Argon blowing pressure (relative pressure): 0.2PMa

[0024] Argon blowing flow rate: 22L / min.

[0025] Molten steel temperature when blowing air: 1690°C

[0026] Argon blowing time: 4.5min.

[0027] Stand still after blowing argon: 2.5min.

[0028] Compared with unpurified by argon blowing, the S content is reduced by 55% on average, the P content is reduced by 30% on average, and the gas content is reduced by 35%.

Embodiment 3

[0029] Embodiment 3: In the steel foundry workshop of a foundry of China First Automobile Group Corporation Casting Co., Ltd., pouring ladle with 5t, blowing nitrogen gas to molten steel of 35CrMnSi steel in the ladle by the breathable plug installed in the air blowing device at the bottom of the ladle, carry out Purification of molten steel.

[0030] Argon blowing pressure (relative pressure): 0.4PMa

[0031] Argon blowing flow rate: 30L / min.

[0032] Molten steel temperature when blowing air: 1670°C

[0033] Argon blowing time: 6min.

[0034] Stand still after blowing argon: 4min.

[0035] Compared with unpurified air blowing, the S content is reduced by 50% on average, the P content is reduced by 30% on average, and the H and O gas content is reduced by 40%.

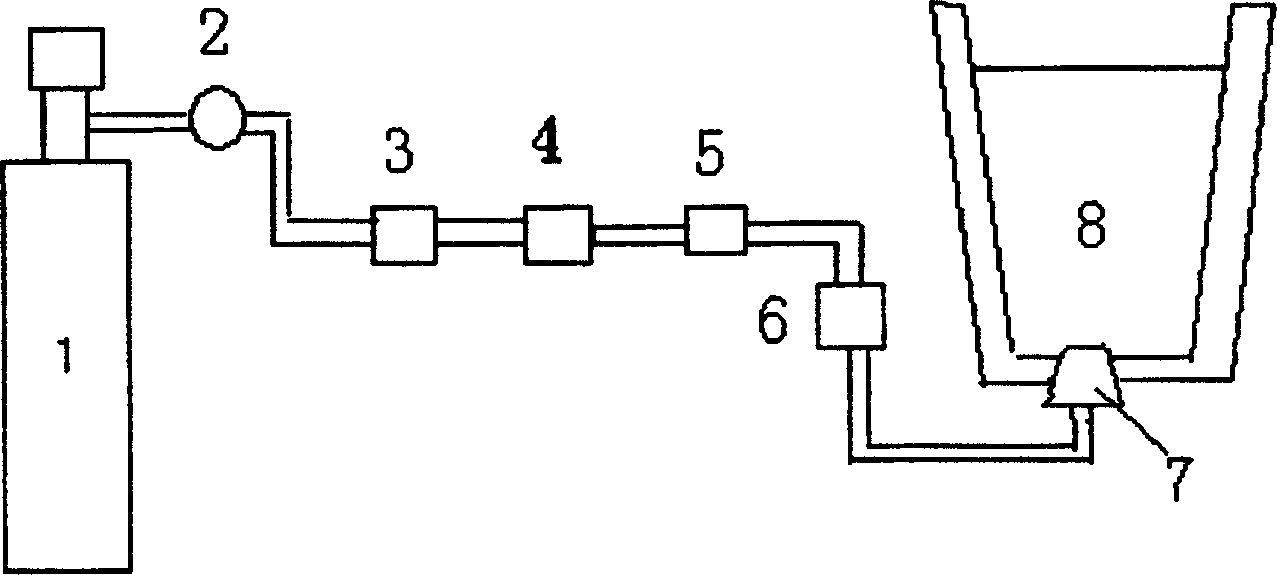

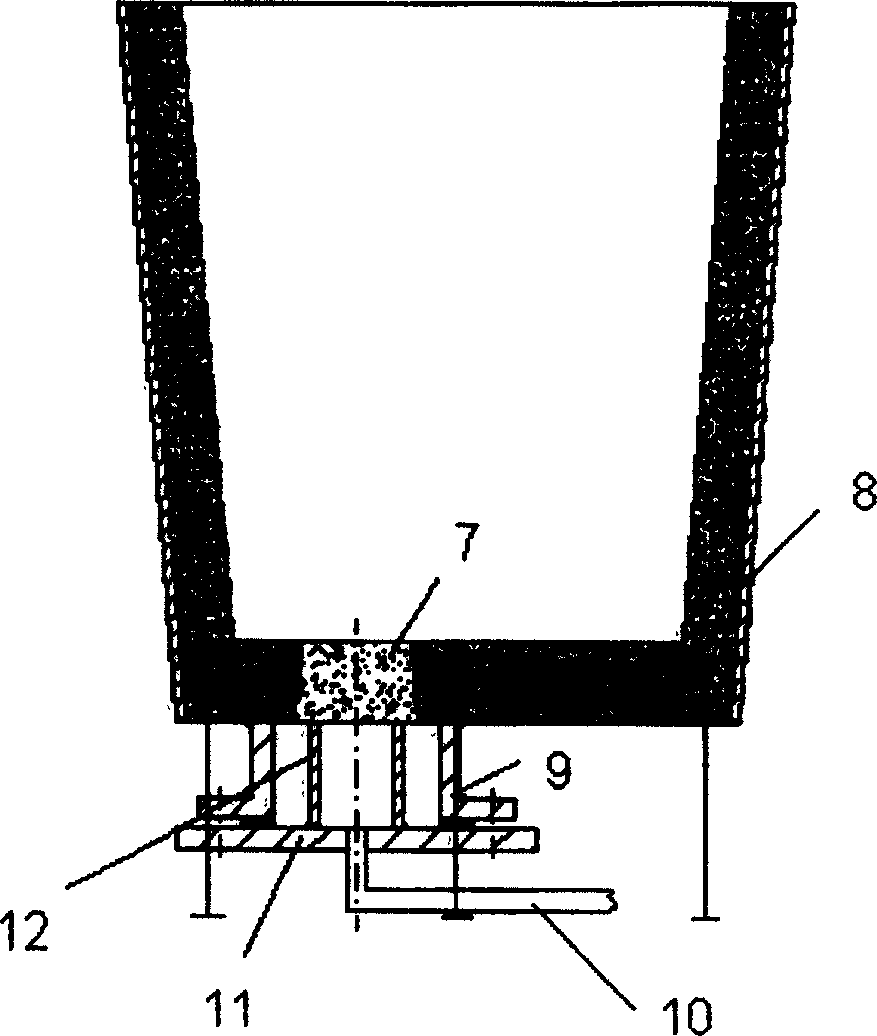

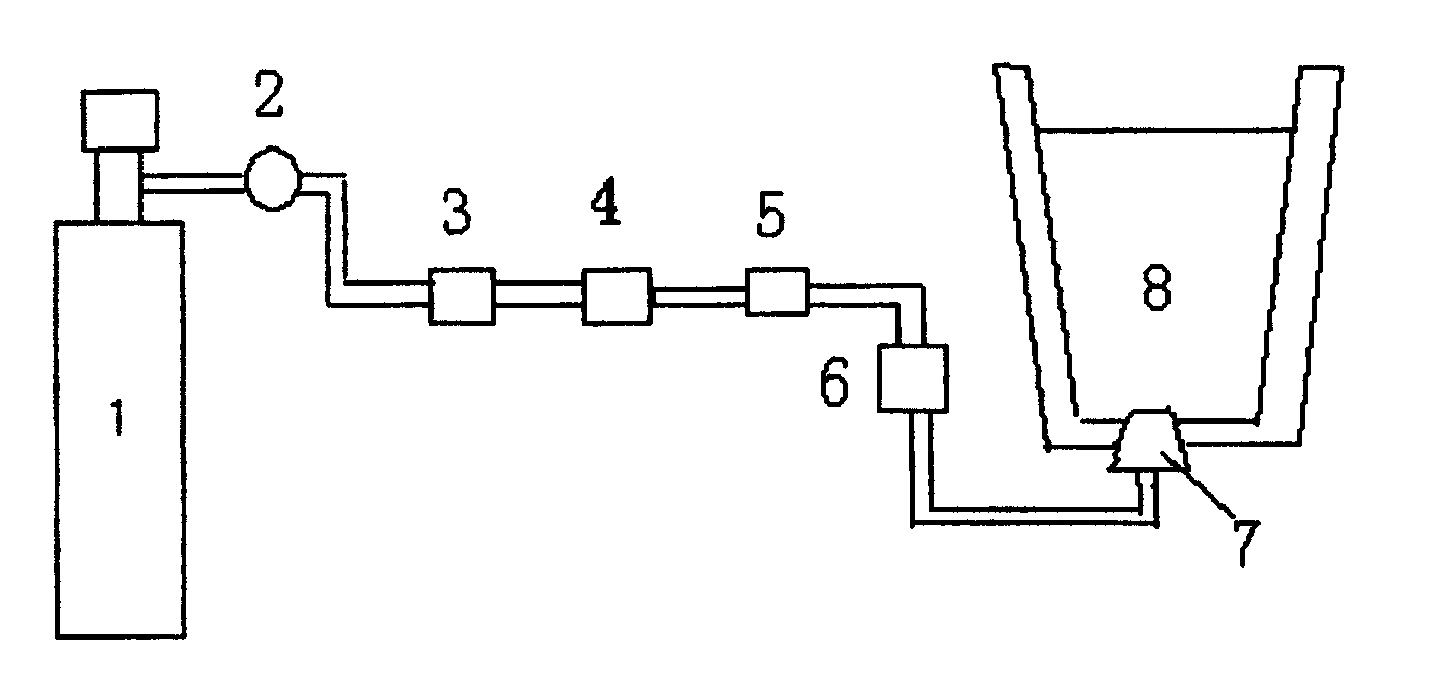

[0036] The blowing device that is used for the bottom of the steel (iron) ladle of the inventive method is to press figure 1 , figure 2 The shown mode is formed: a ventilation plug 7 is installed at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com