Composite modified asphalt and preparation method thereof

A technology of composite modified asphalt and matrix asphalt, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problem that the viscoelasticity and flexibility of modified asphalt cannot meet the corresponding requirements of ultra-thin wear layers, and achieve good cost and Environmental benefits, avoid low temperature easy cracking, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

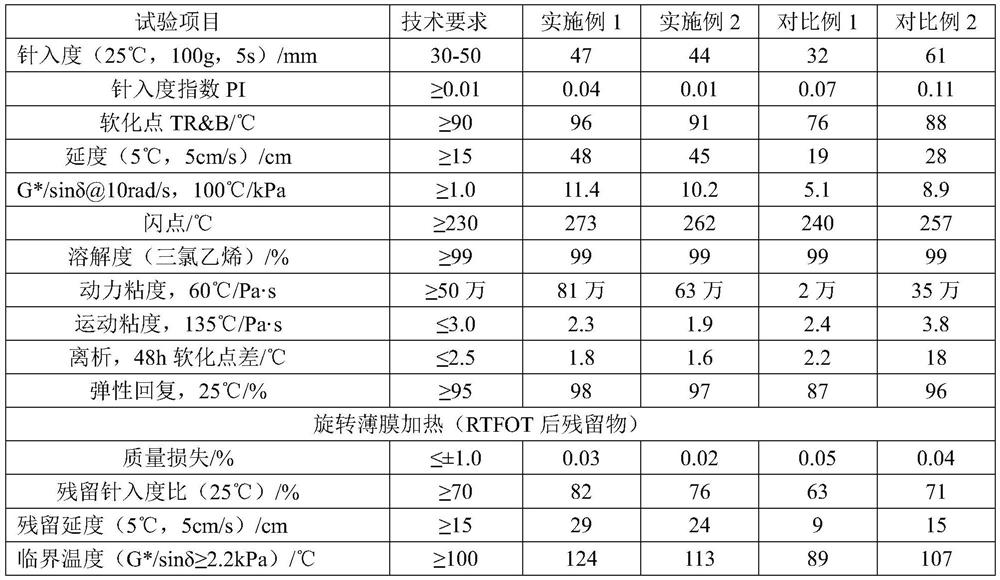

Embodiment 1

[0038] A kind of composite modified asphalt, its preparation method comprises the steps:

[0039] 1) Take 90 parts of base asphalt and heat it to 140°C to melt flow state, add 6 parts of polyisoprene-based modifier and 2 parts of compatibilizer cracked distillate oil to base asphalt, and manually stir for 30 minutes at 150°C , and then add 4 parts of SBS to it and place it in a heat preservation device with a constant temperature of 180°C for high-speed shearing, the shearing machine speed is 7000r / min, and the shearing time is 80min to obtain the mixture A;

[0040] 2) Add 1 part of stabilizer (sulfur and bis-tert-butylperoxycumene mixed in a mass ratio of 2:3) to mixture A, and place it at a constant temperature of 180°C for shearing, and the speed of the shearing machine is 3000r / min, the shearing time is 30min to obtain mixture B;

[0041] 3) The obtained mixture B was placed in a stirring pile with a constant temperature of 160° C. for stirring, the rotational speed of ...

Embodiment 2

[0043] A kind of composite modified asphalt, its preparation method comprises the steps:

[0044] 1) Take 85 parts of base asphalt and heat it to 140°C to melt flow state, add 7 parts of polyisoprene-based modifier and 3 parts of compatibilizer cracked distillate oil into the base asphalt, and manually stir for 30 minutes at 150°C , and then add 4 parts of SBS to it and place it in a heat preservation device with a constant temperature of 190°C for high-speed shearing, the shearing machine speed is 8000r / min, and the shearing time is 90min to obtain the mixture A;

[0045] 2) Add 2 parts of stabilizer (sulfur and bis-tert-butylperoxycumene mixed in a mass ratio of 2:3) to mixture A, and place it at a constant temperature of 180°C for shearing, and the speed of the shearing machine is 2000r / min, the shearing time is 45min to obtain mixture B;

[0046] 3) Put the obtained mixture B in a stirring pile with a constant temperature of 170° C. for stirring, control the speed of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com