Asphalt mixture and preparation method thereof

A kind of asphalt mixture and asphalt technology, which is applied in the field of asphalt mixture and asphalt mixture preparation, can solve the problems of asphalt mixture viscosity reduction, asphalt pavement segregation, asphalt pavement cracks, etc., to enhance crack resistance and reduce air pollution. The effect of good content and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

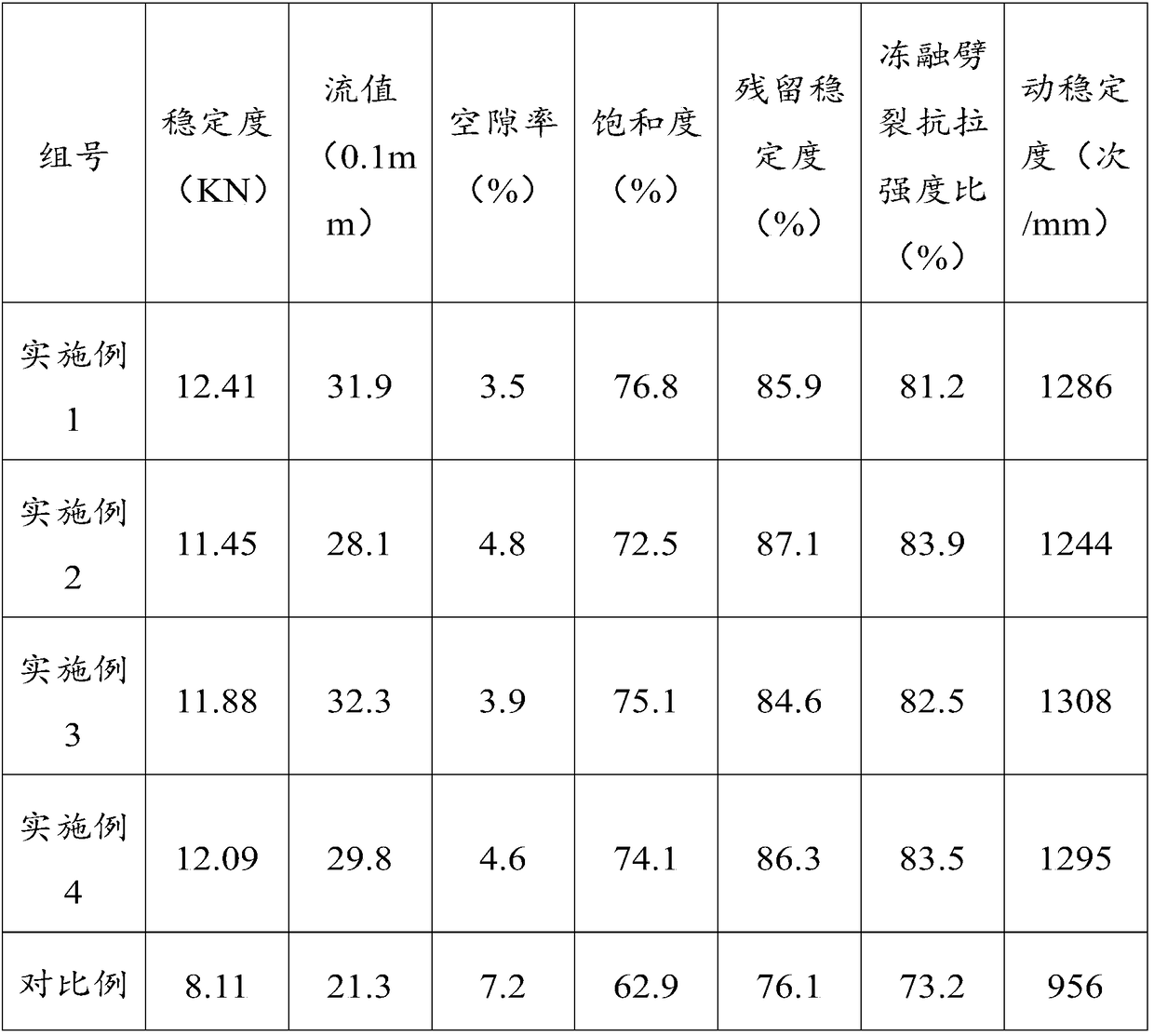

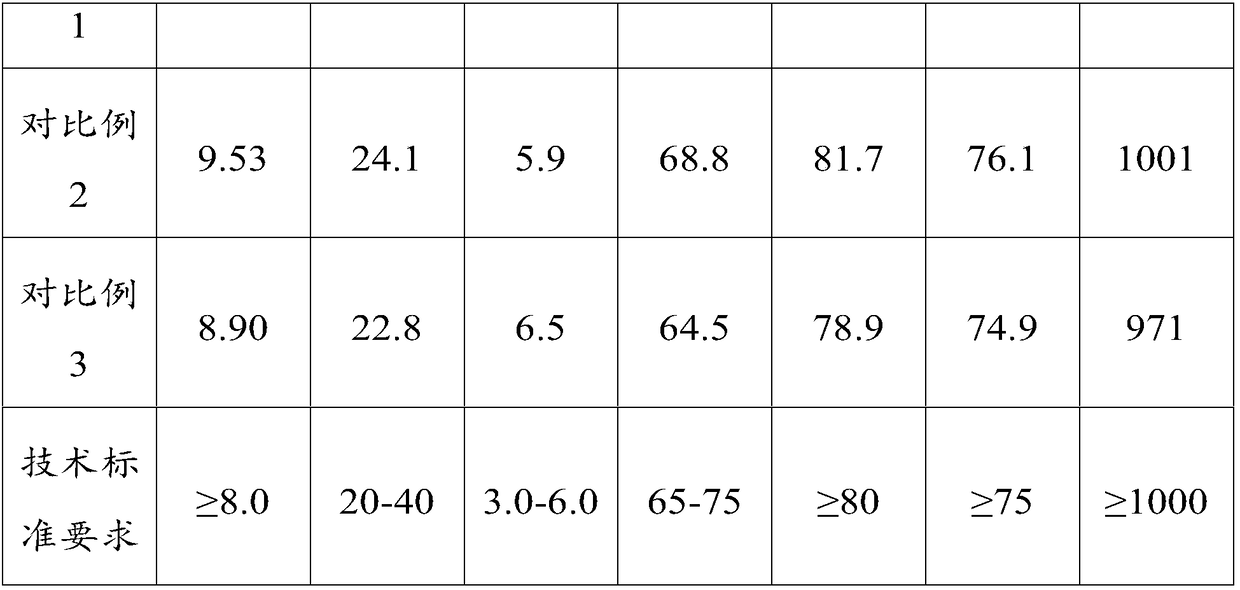

Examples

Embodiment 1

[0032] Prepare materials: prepare 20 parts by weight of asphalt, 5 parts by weight of rubber, 6 parts by weight of water-soluble silicate, 3 parts by weight of ceramsite, 5 parts by weight of perlite, 3 parts by weight of slag, 3 parts by weight of river sand.

[0033] The first hot melt: preheat the hot melt tank to 150°C, add asphalt into the preheated hot melt tank, heat at 150°C for 30 minutes, then raise the temperature to 170°C, and stir at 170°C 15min.

[0034] The second hot melting: cool the hot-melted asphalt to 155°C, add water-soluble silicate and ceramsite (10 mesh) to the hot-melted asphalt, at a temperature of 160°C, at a speed of 300r / min and stirred for 20min. The above-mentioned water-soluble silicate is sodium silicate.

[0035] The third hot melt: add rubber to the mixture after the second hot melt, and heat stir for 15 minutes at a temperature of 170° C. and a rotational speed of 500 r / min. The above-mentioned rubber is styrene-butadiene rubber.

[0...

Embodiment 2

[0038] Prepare materials: Prepare 30 parts by weight of asphalt, 6 parts by weight of rubber, 8 parts by weight of water-soluble silicate, 5 parts by weight of ceramsite, 8 parts by weight of perlite, 5 parts by weight of slag, 5 parts by weight of river sand.

[0039] The first hot melt: preheat the hot melt tank to 160°C, add asphalt into the preheated hot melt tank, heat at 160°C for 20 minutes, then raise the temperature to 185°C, and stir at 185°C 10min.

[0040] The second hot melting: cool the hot-melted asphalt to 165°C, add water-soluble silicate and ceramsite (30 mesh) to the hot-melted asphalt, at a temperature of 165°C, at a speed of 200r / min and stirred for 30min. The above-mentioned water-soluble silicate is potassium silicate.

[0041] The third heat melting: add rubber to the mixture after the second heat melting, and heat stir for 25 minutes at a temperature of 180° C. and a rotation speed of 400 r / min. The rubber mentioned above is butadiene rubber.

[...

Embodiment 3

[0044] Prepare materials: Prepare 25 parts by weight of asphalt, 5.5 parts by weight of rubber, 7 parts by weight of water-soluble silicate, 4 parts by weight of ceramsite, 7 parts by weight of perlite, 4 parts by weight of slag, 4 parts by weight of river sand.

[0045] The first hot melt: preheat the hot melt tank to 155°C, add asphalt into the preheated hot melt tank, heat at 155°C for 25 minutes, then raise the temperature to 175°C, and stir at 175°C 12min.

[0046] The second hot melt: cool the melted asphalt to 160 ° C, add water-soluble silicate and ceramsite (20 mesh) to the hot melted asphalt, at a temperature of 162 ° C, at a speed of 250r / min and stirred for 25min. The above-mentioned water-soluble silicates are sodium silicate and lithium silicate.

[0047] The third hot melt: add rubber to the mixture after the second hot melt, and heat stir for 20 minutes at a temperature of 175° C. and a rotational speed of 450 r / min. The above-mentioned rubbers are natural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com