High-performance concrete and preparation method thereof

A technology of high-performance concrete and machine-made sand, applied in melt spinning, rayon manufacturing, climate sustainability, etc., can solve threats to the safety and usability of concrete structures, cracking of concrete protective layers, and destruction of passivation films and other problems, to achieve the effect of inhibiting ion erosion, stable concrete quality, and uniform volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

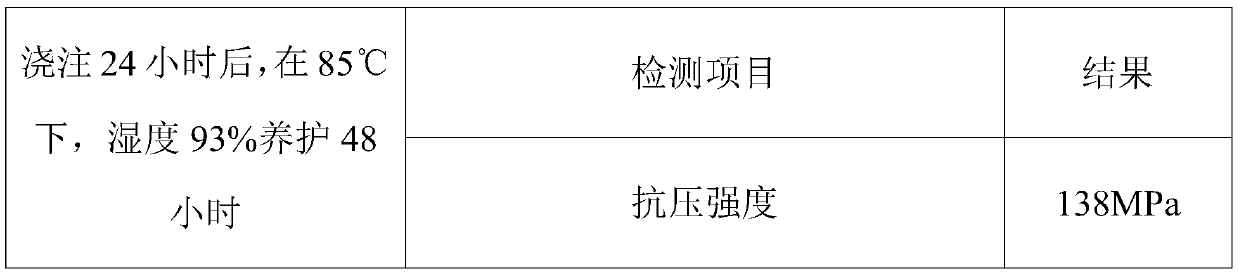

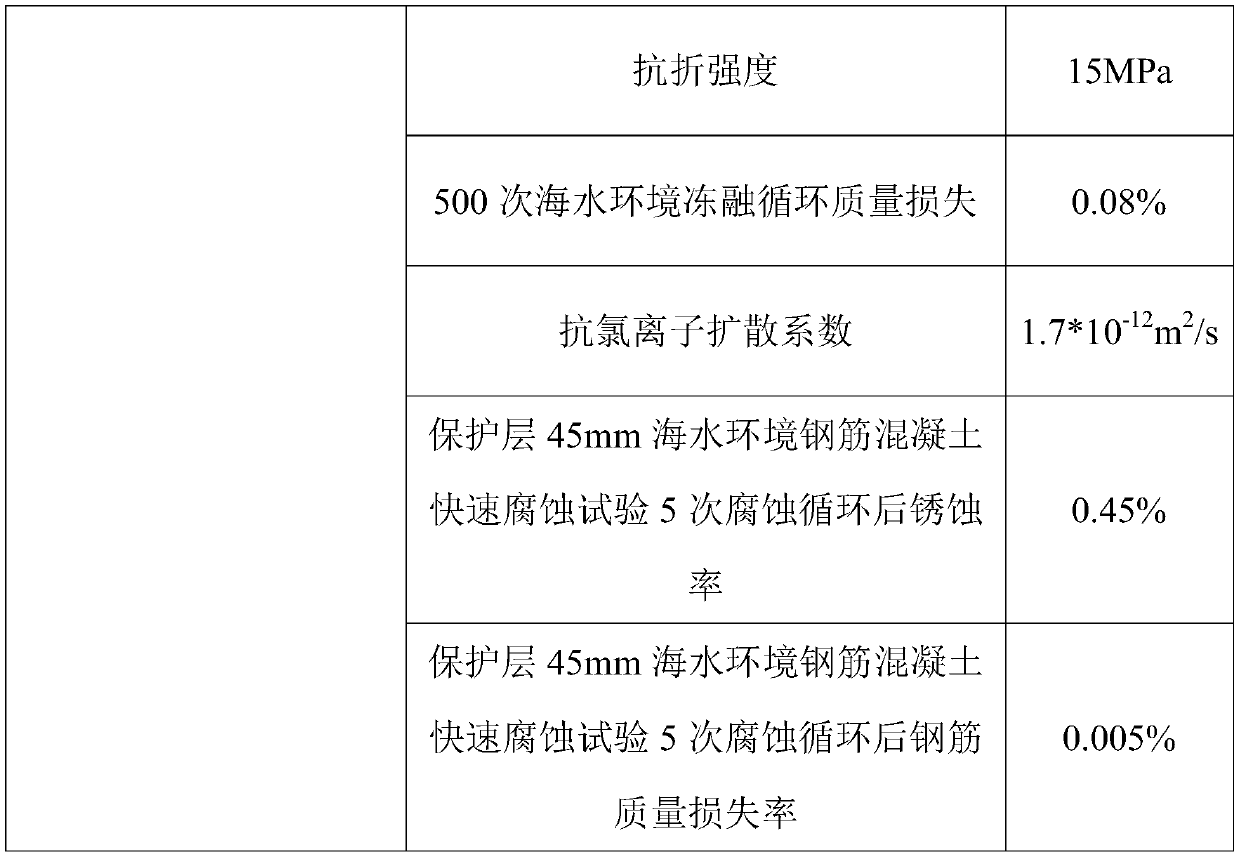

Embodiment 1

[0031] A high-performance concrete comprising the following raw materials in parts by weight:

[0032] Machine-made sand 100-110, crushed stone 130-140, sea sand 30-45, sea water 30-45, Portland cement 25-35, silicon powder 30-32, polypropylene fiber 25-30, steel slag powder 20-28, compensation for shrinkage Agent 20-25, polystyrene foam particles 20-22, silica sand particles 16-20, steel fibers 15-20, desulfurization gypsum 15-18, red mud particles 15-18, slag powder 15-18, fly ash 12-16 , Nanometer dolomite particles 10-15, phosphorus slag powder 10-15, aluminate cement 8-10, reef powder 8-10, ceramic particles 8-10, alginate 8-10, calcium formate 5-8, sub Calcium nitrate 5-7, pyridine-3-carboxylic acid 4-5, polycarboxylate superplasticizer 2-5, white carbon black 2-3, natron 1-1.5, caustic soda 0.8-1.2, crystal wax 1-2 , polyvinyl alcohol 1-1.5, diethylene glycol monobutyl ether 0.5-1, defoamer 0.3-0.7, azodicarbonamide 0.2-0.5;

[0033] The polypropylene fiber is made of...

Embodiment 2

[0047] A high-performance concrete comprising the following raw materials in parts by weight:

[0048] Machine-made sand 100-110, crushed stone 130-140, sea sand 30-45, sea water 30-45, Portland cement 25-35, silicon powder 30-32, polypropylene fiber 25-30, steel slag powder 20-28, compensation for shrinkage Agent 20-25, polystyrene foam particles 20-22, silica sand particles 16-20, steel fibers 15-20, desulfurization gypsum 15-18, red mud particles 15-18, slag powder 15-18, fly ash 12-16 , Nanometer dolomite particles 10-15, phosphorus slag powder 10-15, aluminate cement 8-10, reef powder 8-10, ceramic particles 8-10, alginate 8-10, calcium formate 5-8, sub Calcium nitrate 5-7, pyridine-3-carboxylic acid 4-5, polycarboxylate superplasticizer 2-5, white carbon black 2-3, natron 1-1.5, caustic soda 0.8-1.2, crystal wax 1-2 , polyvinyl alcohol 1-1.5, diethylene glycol monobutyl ether 0.5-1, defoamer 0.3-0.7, azodicarbonamide 0.2-0.5;

[0049] The polypropylene fiber is made of...

Embodiment 3

[0070] A high-performance concrete comprising the following raw materials in parts by weight:

[0071] Machine-made sand 100-110, crushed stone 130-140, sea sand 30-45, sea water 30-45, Portland cement 25-35, silicon powder 30-32, polypropylene fiber 25-30, steel slag powder 20-28, compensation for shrinkage Agent 20-25, polystyrene foam particles 20-22, silica sand particles 16-20, steel fibers 15-20, desulfurization gypsum 15-18, red mud particles 15-18, slag powder 15-18, fly ash 12-16 , Nanometer dolomite particles 10-15, phosphorus slag powder 10-15, aluminate cement 8-10, reef powder 8-10, ceramic particles 8-10, alginate 8-10, calcium formate 5-8, sub Calcium nitrate 5-7, pyridine-3-carboxylic acid 4-5, polycarboxylate superplasticizer 2-5, white carbon black 2-3, natron 1-1.5, caustic soda 0.8-1.2, crystal wax 1-2 , polyvinyl alcohol 1-1.5, diethylene glycol monobutyl ether 0.5-1, defoamer 0.3-0.7, azodicarbonamide 0.2-0.5;

[0072] The polypropylene fiber is made of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com