Composite nanostructure based on three-dimensional porous transition metal carbide Ti3C2MXene and general preparation method thereof

A composite nanostructure and three-dimensional porous technology, applied in the field of nanomaterials, can solve problems such as limiting the efficient application of surfaces and interfaces, limiting the uniform growth and compounding of inorganic nanometers, and achieving excellent structural stability, easy large-scale production, and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

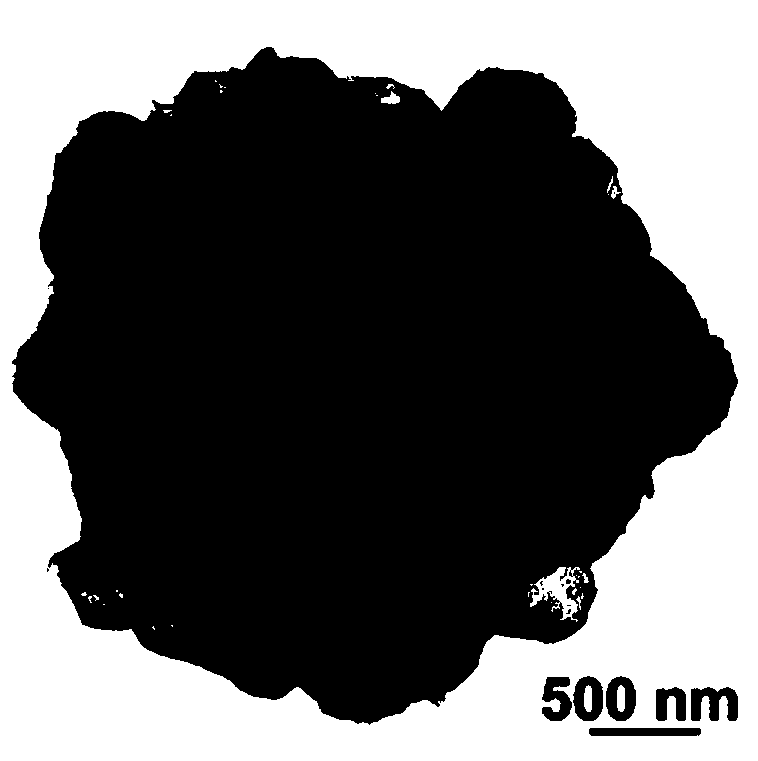

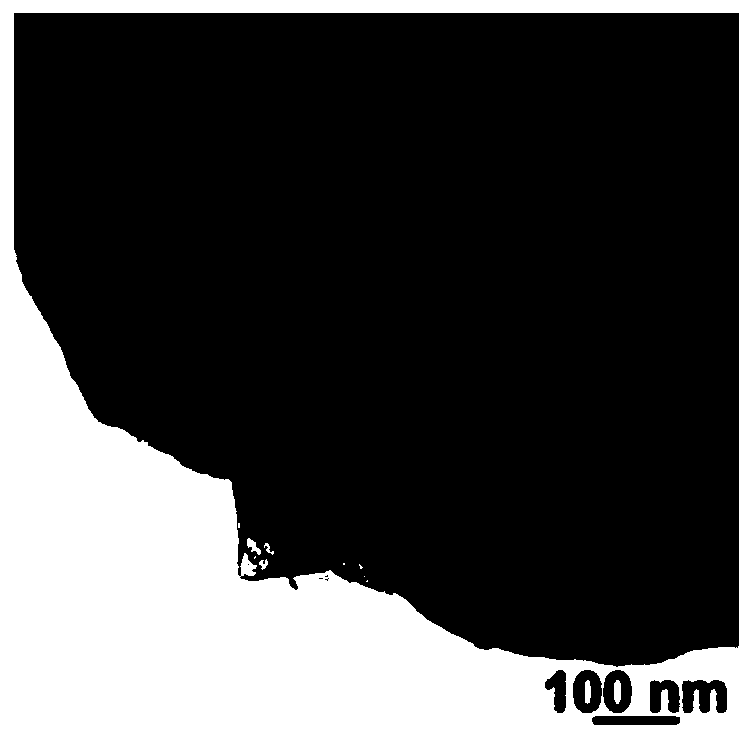

[0032] Example 1 Three-dimensional porous Ti loaded with cobalt sulfide nanoparticles 3 C 2 The preparation method of MXene (Scheme 1)

[0033] 1) Mix 5mL20mgmL -1 Ti 3 C 2 MXene and 50 mg of cobalt-containing metal-organic framework compound ZIF-67 were dispersed in 100 mL of ethanol, and ultrasonically dispersed for 10 min to prepare a precursor solution.

[0034] 2) Using an ultrasonic atomizer to atomize the precursor solution obtained in step 1) into aerosol droplets with a size of about several microns. With Ar gas as the carrier gas, the aerosol micro-droplets were blown into a tube furnace with a preset temperature of 300 °C to make them dry quickly, and three-dimensional Ti 3 C 2 MXene coated ZIF-67 nanoparticles. The product particles obtained had an average size of about 3.5 μm.

[0035] 3) Under hydrogen sulfide gas and argon atmosphere, the three-dimensional Ti obtained in step 2) 3 C 2 MXene-coated ZIF-67 nanoparticles were calcined in a high-temperat...

Embodiment 2

[0036] Example 2 Three-dimensional porous Ti loaded with cobalt phosphide nanoparticles 3 C 2 The preparation method of MXene (Scheme 1)

[0037] 1) Dilute 5mL10mgmL -1 Ti 3 C 2 MXene and 500 mg cobalt-containing metal-organic framework compound ZIF-67 were dispersed in 50 mL ethanol, and ultrasonically dispersed for 60 min to prepare a precursor solution.

[0038] 2) Using an ultrasonic atomizer to atomize the precursor solution described in step 1) into aerosol micro-droplets with a size of several microns. With Ar gas as the carrier gas, the aerosol micro-droplets were blown into a tube furnace with a preset temperature of 400 °C to make them dry quickly, and three-dimensional Ti 3 C 2 MXene coated ZIF-67 nanoparticles. The product particles obtained had an average size of about 3.5 μm.

[0039] 3) Under the protection of phosphine gas and nitrogen gas, the three-dimensional Ti obtained in step 2) 3 C 2 MXene-coated ZIF-67 nanoparticles were calcined in a high-...

Embodiment 3

[0040] The preparation method of the three-dimensional porous MXene of embodiment 3 load cobalt hydroxide nanosheets (scheme two)

[0041] 1) Dilute 100mL0.5mgmL -1 Ti 3 C 2 MXene and 5000 mg cobalt-containing metal-organic framework compound ZIF-67 were dispersed in 50 mL ethanol, and ultrasonically dispersed for 60 min to prepare a precursor solution.

[0042] 2) Using an ultrasonic atomizer to atomize the precursor solution described in 1) into aerosol micro-droplets with a size of several microns. With Ar gas as the carrier gas, the aerosol micro-droplets were blown into a tube furnace with a preset temperature of 300 °C to make them dry quickly, and three-dimensional Ti 3 C 2 MXene coated ZIF-67 nanoparticles. The product particles obtained had an average size of about 3.5 μm.

[0043] 3) the three-dimensional Ti obtained in step 2) 3 C 2 MXene-coated ZIF-67 nanoparticles were placed in the corresponding ethanol solution of cobalt chloride (20 mg mL -1 , 20mL)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com