Honeycomb polymer-based bionic porous scaffold material and preparation method thereof

A technology of porous scaffolds and honeycomb pores is applied in the field of honeycomb polymer-based biomimetic porous scaffold materials and their preparation, which can solve the problems of unsuitable storage and direct application, poor connectivity, residual cell debris and immunogenicity, etc. The effect of avoiding immunogenicity and potential infectious disease risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

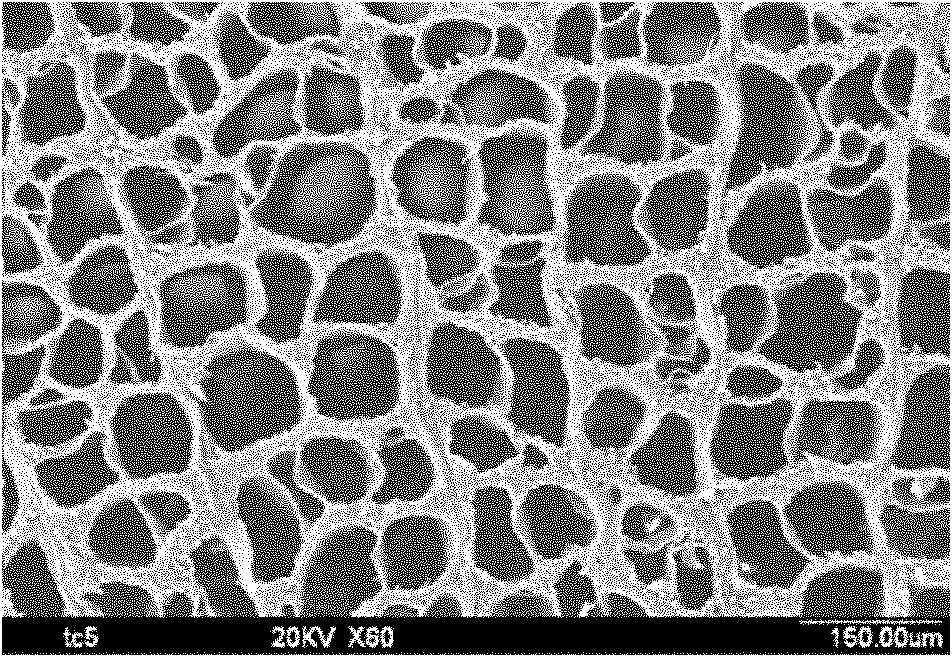

[0028] 1) Plant tissue template treatment: take wisteria as the plant tissue template and soak it in ammonia water with a volume concentration of 5% for 18 hours after shaping and processing. Slowly stir during soaking, then wash with distilled water until neutral, freeze-dry and set aside, after treatment The botanical template for the wisteria see figure 1 ,Depend on figure 1 It can be seen that wisteria has a honeycomb structure arranged in parallel and separated by radial contours. The diameter of the honeycomb pores is about 100 μm, and the thickness of the pore walls is 10-20 μm. The walls of the honeycomb pores contain a large number of small pores;

[0029] 2) Vacuum carbonization: place the freeze-dried plant tissue template in a vacuum furnace, raise the temperature of the furnace from room temperature to 500 °C at a rate of 0.5 °C / min, keep it warm for 6 hours and then cool it to room temperature with the furnace to obtain a porous carbon body ;

[0030] 3) Molten...

Embodiment 2

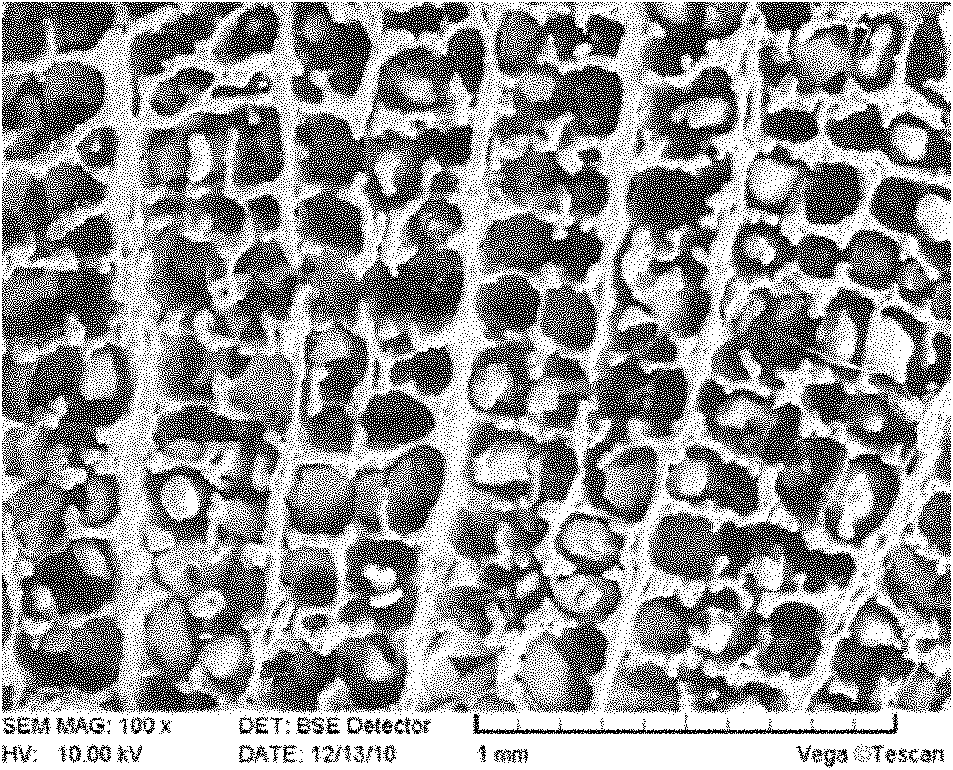

[0037] 1) Plant tissue template treatment: take pine wood as the plant tissue template and soak it in ammonia water with a volume concentration of 10% for 24 hours after shaping and processing. Slowly stir during soaking, then wash with distilled water until neutral, freeze-dry and set aside;

[0038] 2) Vacuum carbonization: put the freeze-dried plant tissue template in a vacuum furnace, raise the temperature of the furnace from room temperature to 600 °C at a rate of 1 °C / min, keep it warm for 4 hours and then cool it down to room temperature with the furnace to obtain a porous carbon body ;

[0039] 3) Melting salt infiltration: the porous carbon body is embedded in the water-soluble salt CaCl with a particle size of 200 mesh 2 powder, and put it in a vacuum furnace, raise the temperature from room temperature to 950 °C at a rate of 3 °C / min, keep warm for 4 hours and then cool to room temperature with the furnace to obtain a porous carbon / water-soluble salt composite;

[...

Embodiment 3

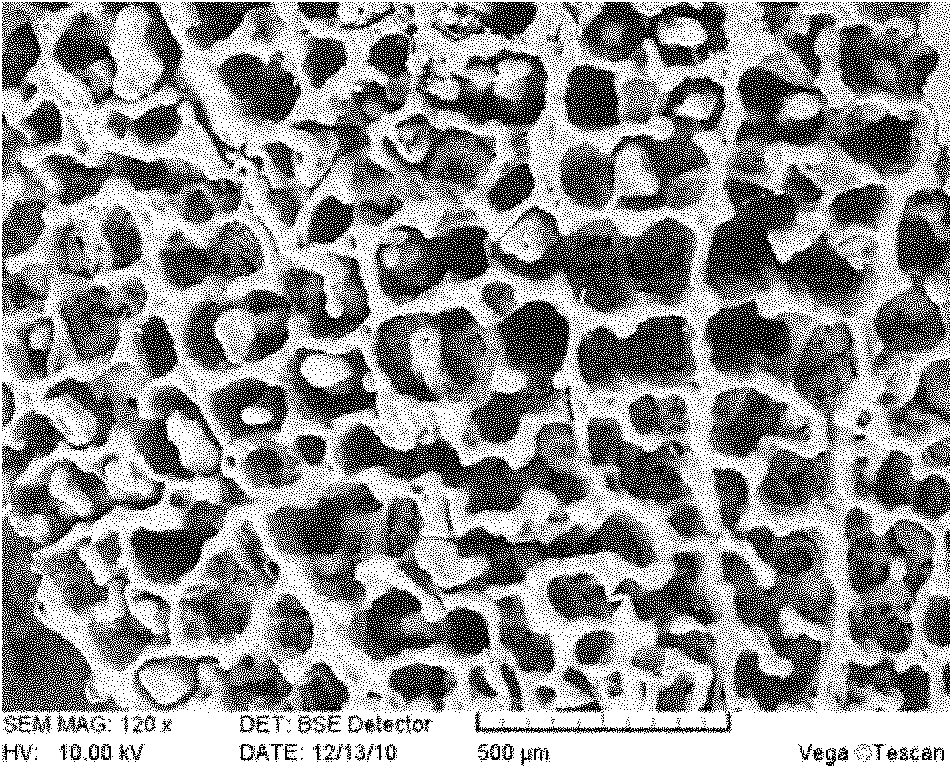

[0046] 1) Plant tissue template treatment: take wisteria as the plant tissue template and soak it in ammonia water with a volume concentration of 8% for 24 hours after shaping and processing, slowly stir during soaking, then wash with distilled water until neutral, freeze-dry and set aside;

[0047] 2) Vacuum carbonization: put the freeze-dried plant tissue template in a vacuum furnace, raise the temperature of the furnace from room temperature to 550 °C at a rate of 0.2 °C / min, keep it warm for 4 hours and then cool it down to room temperature with the furnace to obtain a porous carbon body ;

[0048] 3) Molten salt infiltration: Embed the porous carbon body in water-soluble salt KCl powder with a particle size of 200 mesh, and place it in a vacuum furnace, and raise the temperature from room temperature to 1000 °C at a rate of 2 °C / min. After 3 hours, cool to room temperature with the furnace to obtain a porous carbon / water-soluble salt composite;

[0049] 4) Oxidation and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com