Oxygen evolution reaction (OER) catalyst based on composite structure of MXene and metal-organic frameworks (MOFs) and synthesis method of catalyst

A technology of metal-organic framework and oxygen evolution reaction, applied in the field of energy and catalysis, and nanomaterials, can solve the problems of poor conductivity and poor structural stability of MOFs, and achieve the effects of easy control, large-scale production, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The preparation method of the composite nanocatalyst based on MXene and NiFe-BDC MOFs

[0034] 1) Disperse MXene in water at normal temperature and pressure to prepare 2 mL of 10 mg mL -1 the dispersion liquid;

[0035] 2) Dissolve 1.0mmol of nickel acetate, 0.2mmol of iron nitrate and 1.2mmol of terephthalic acid in 30mL of N,N-dimethylformamide (DMF) and 2mL of ethanol at normal temperature and pressure to form a homogeneous solution;

[0036] 3) uniformly mixing the MXene dispersion prepared in step 1) with the metal salt / organic ligand solution prepared in step 2) at normal temperature and pressure;

[0037] 4) Add 0.8 mL of acid-binding agent triethylamine to the mixed solution prepared in step 3) at normal temperature and pressure, and react for 2 hours under stirring conditions. After the reaction, use ethanol to centrifugally wash, and then vacuum-dry.

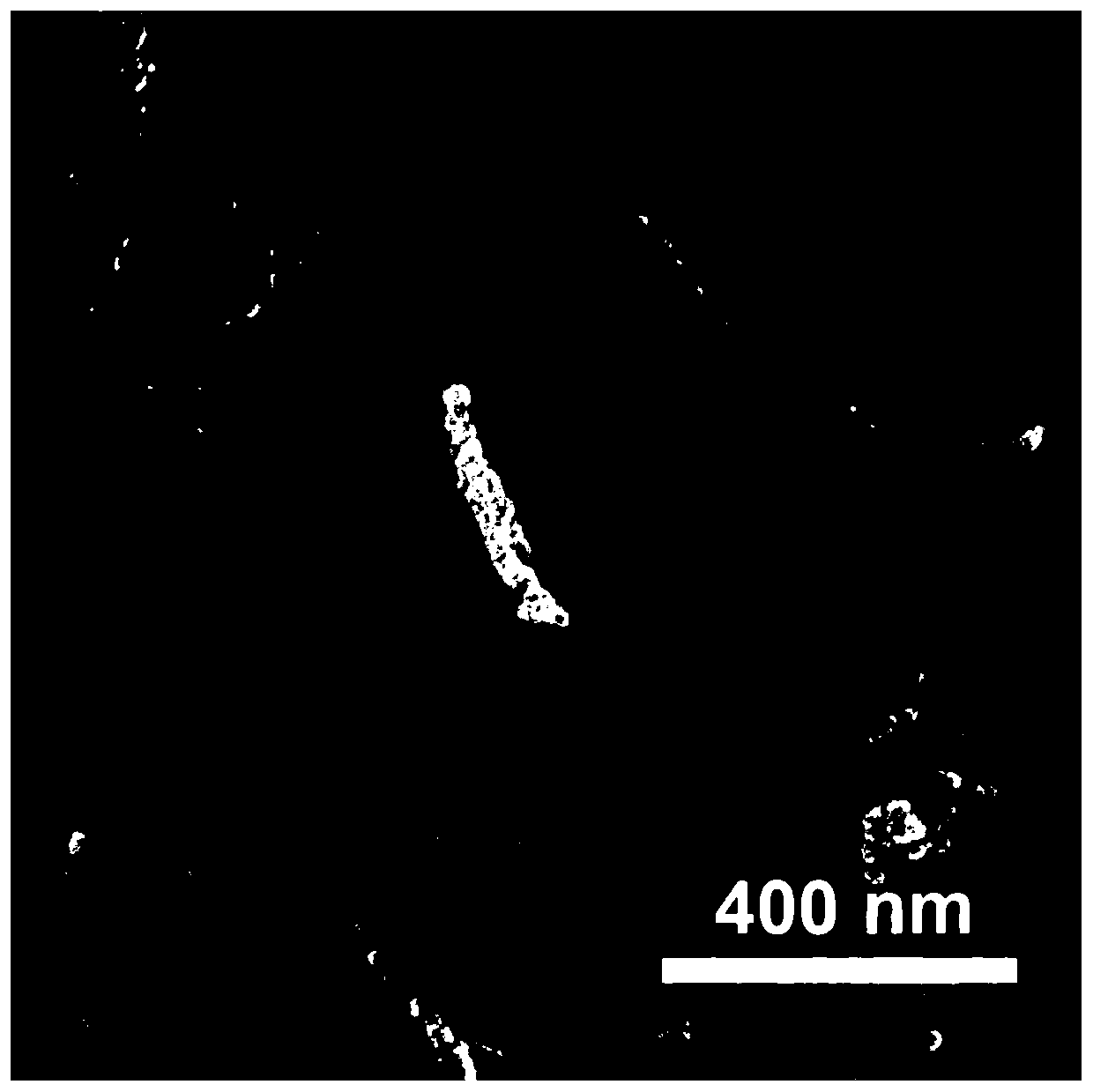

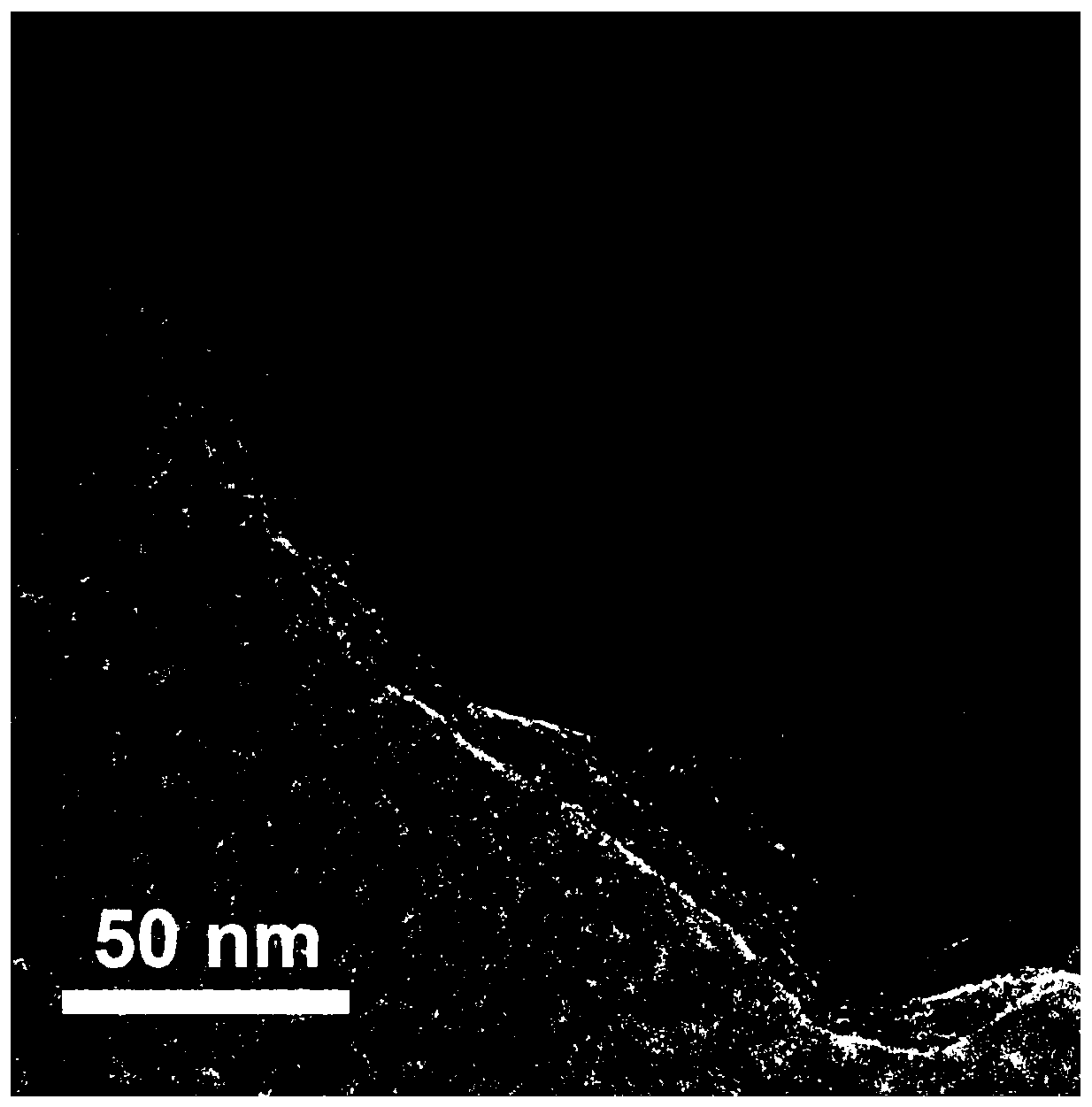

[0038] The obtained product is a two-dimensional nanosheet with an average size of about 100-5...

Embodiment 2

[0039] Example 2 Preparation method of composite nanocatalyst based on MXene and NiCo-BDC MOFs

[0040] 1) Disperse MXene in water at normal temperature and pressure to prepare 2 mL of 5 mg mL -1 the dispersion liquid;

[0041]2) Dissolve 0.6mmol of nickel chloride, 0.6mmol of cobalt chloride and 1.2mmol of terephthalic acid in 30mL of N,N-dimethylformamide (DMF) and 2mL of ethanol at normal temperature and pressure to form a homogeneous solution;

[0042] 3) uniformly mixing the MXene dispersion prepared in step 1) with the metal salt / organic ligand solution prepared in step 2) at normal temperature and pressure;

[0043] 4) Add 0.5 mL of acid-binding agent triethylamine to the mixed solution prepared in step 3) at normal temperature and pressure, and react under stirring conditions for 2 h. After the reaction, use ethanol to wash centrifugally, and then vacuum-dry.

[0044] The obtained product is a two-dimensional nanosheet with an average size of about 100-500nm and load...

Embodiment 3

[0045] Example 3 Preparation method of composite nanocatalyst based on MXene and NiMn-BDC MOFs

[0046] 1) Disperse MXene in water at normal temperature and pressure to prepare 2mL with a concentration of 15mg mL -1 the dispersion liquid;

[0047] 2) Dissolve 0.2mmol of nickel acetate, 1.0mmol of manganese nitrate and 1.2mmol of terephthalic acid in 28mL of N,N-dimethylformamide (DMF) and 4mL of ethanol at normal temperature and pressure to form a homogeneous solution;

[0048] 3) uniformly mixing the MXene dispersion prepared in step 1) with the metal salt / organic ligand solution prepared in step 2) at normal temperature and pressure;

[0049] 4) Add 1.0 mL of acid-binding agent triethylamine to the mixed solution prepared in step 3) at normal temperature and pressure, and react for 4 hours under stirring conditions. After the reaction, use ethanol to wash centrifugally, and then vacuum-dry.

[0050] The obtained product is a two-dimensional nanosheet with an average size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com