Preparation method of curved conformal microstrip antenna array surface

A microstrip antenna and antenna array technology, applied in antenna arrays, individually powered antenna arrays, antennas, etc., can solve problems such as the inability to manufacture curved antenna circuit boards, avoid long-term reliability problems, shorten size, avoid The effect of deteriorating electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

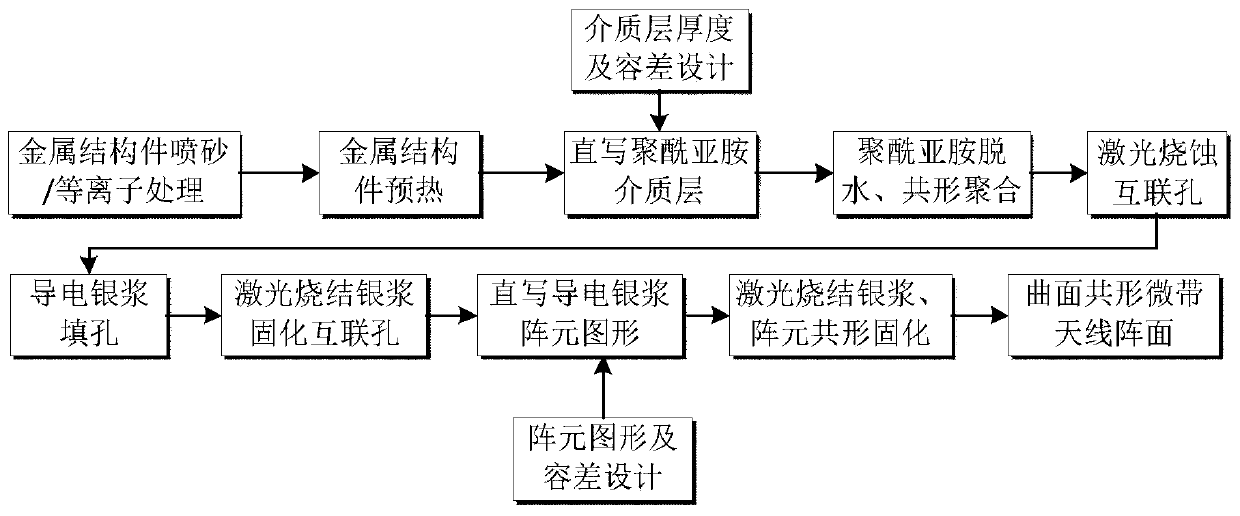

Method used

Image

Examples

Embodiment Construction

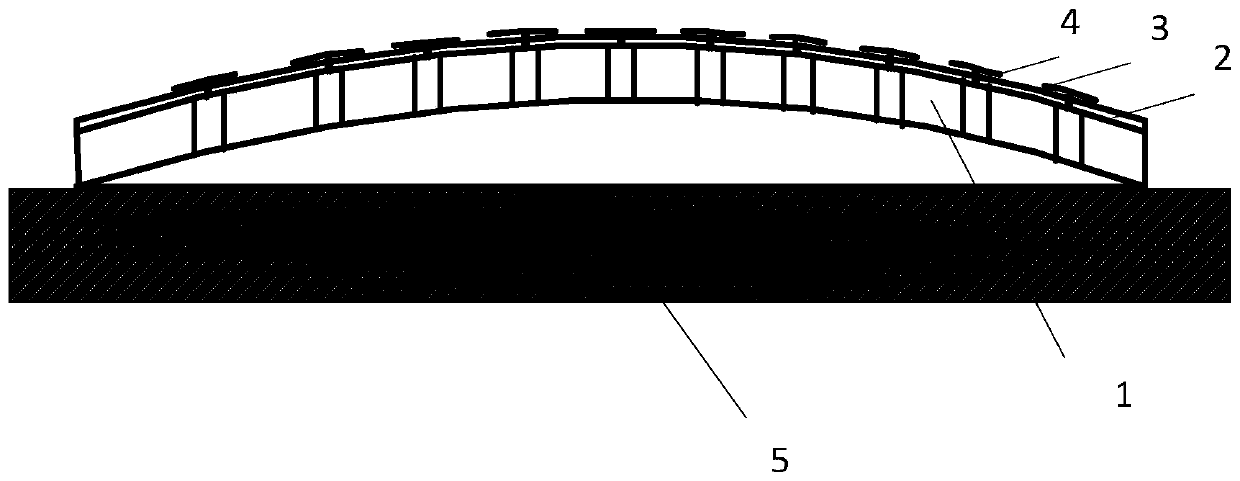

[0017] refer to Figure 1-Figure 2. According to the present invention, the microstrip patch is selected as the antenna conformal array unit, and the curved antenna array is directly printed on the metal structure. The carrier 1 is fixed on the heating substrate 5 for preheating; use the direct writing pen A to write the polyimide precursor solution layer by layer on the sandblasting surface of the metal carrier 1 according to the shape and size of the dielectric layer 2 of the microstrip antenna front until the total thickness requirements After the surface of the polyimide precursor solution is dry, the temperature of the substrate 5 is raised to dehydrate the polyimide precursor solution and polymerize on the surface of the metal carrier 1 to form a conformal dielectric layer 2 of the microstrip antenna front; The position of the array element of the imide dielectric layer 2 is ablated by pulse laser to form the bottom hole of the vertical interconnection hole 3, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com