Superhigh-pressure pressure-reducing valve performance testing bench

A pressure reducing valve and ultra-high pressure technology, which is used in the testing of mechanical components, the use of stable tension/pressure to test the strength of materials, and the testing of machine/structural components, etc. It can solve the problems of difficult development of pressure reducing valves and high inlet pressure , to achieve the effect of perfect function, stable performance and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

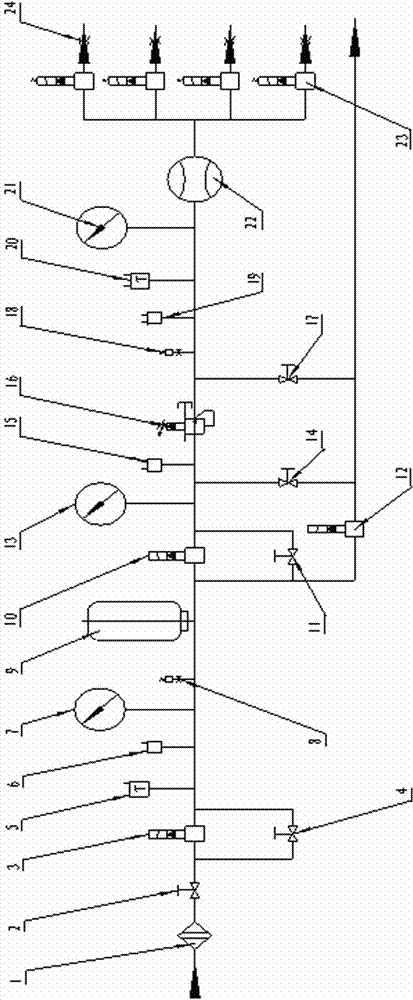

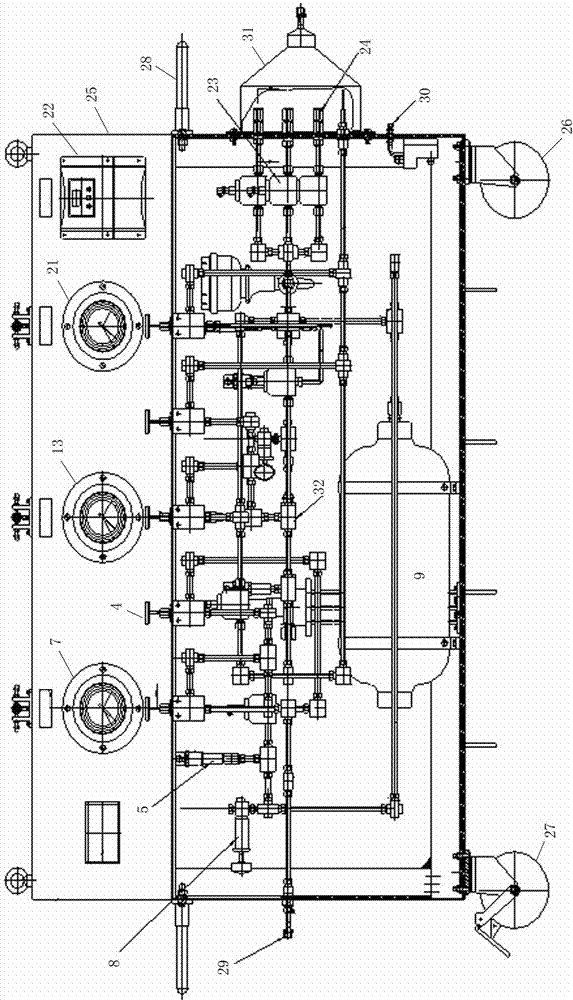

[0023] Such as figure 2 As shown, the box body 25 is a piano-type closed structure, and a camera seat is installed on the top surface of the box body, and the camera seat aligns the camera with the pressure gauge through a cantilever tube structure; the bottom surface of the box body is provided with directional wheels 26 and universal wheels 27, and the box body There are push-pull handrails 28 on both sides; an inflatable nozzle 29 connected to the booster pump system is installed on one side of the box; a low-pressure gas distribution nozzle 30, a wire connector, a signal wire connector and a The gas collecting hood 31 is connected with the helium recovery system through pipelines. Such as figure 1 As shown, the filter 1 in the box is connected to the gas filling port of the gas cylinder 9 through a pipeline, the gas outlet of the gas cylinder is connected to the air inlet of the pressure reducing valve 16 through a pipeline, and the gas outlet of the pressure reducing va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com