High-strength and high-plasticity eutectic high-entropy alloy and preparation method thereof

A high-entropy alloy and high-plasticity technology, which is applied in the field of high-strength, high-plasticity eutectic high-entropy alloy and its preparation, can solve the problems of easy segregation, inability to have high strength and high plasticity at the same time, and poor fluidity, so as to achieve difficult element segregation, Improves anti-oxidation performance and improves high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

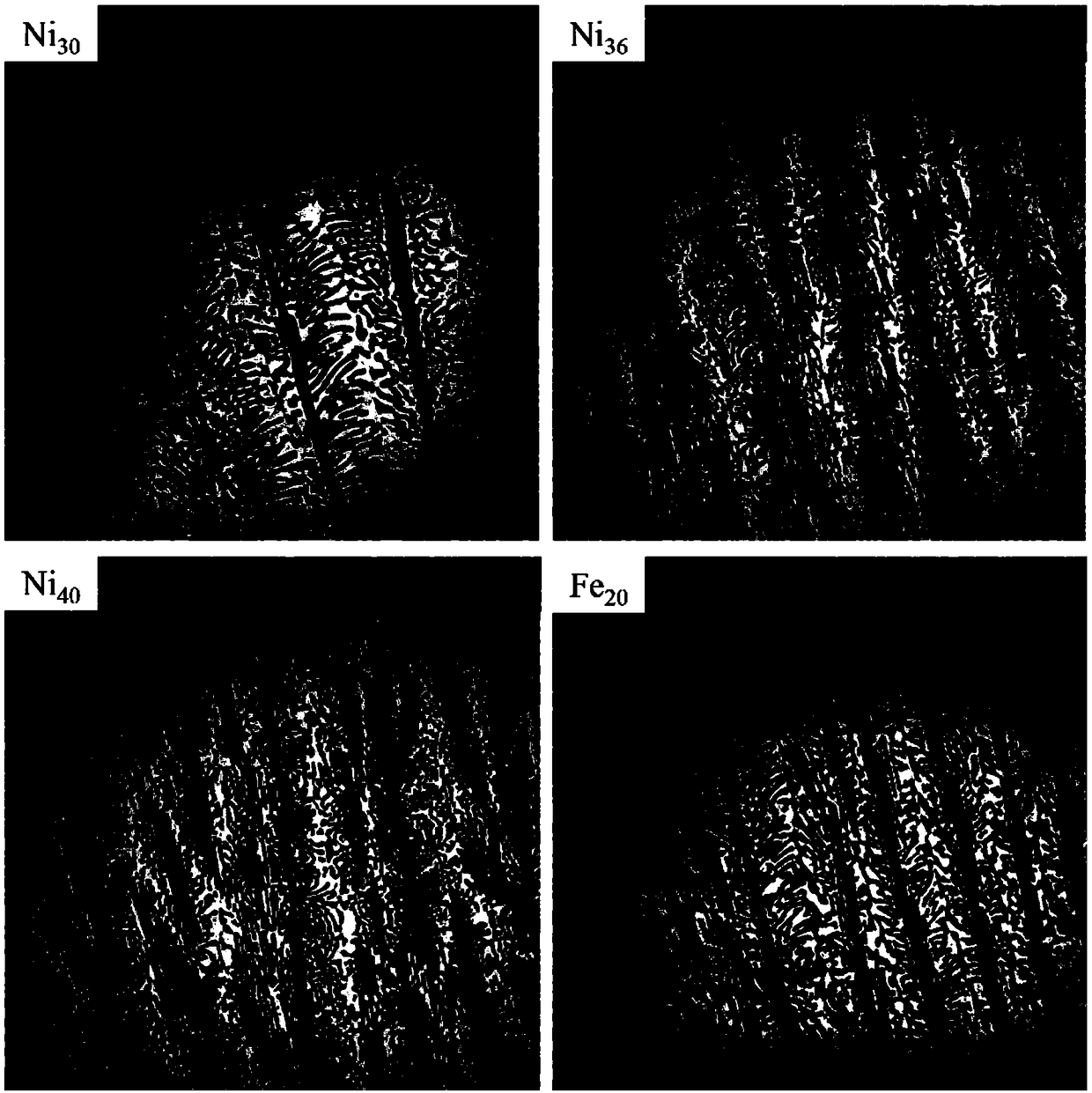

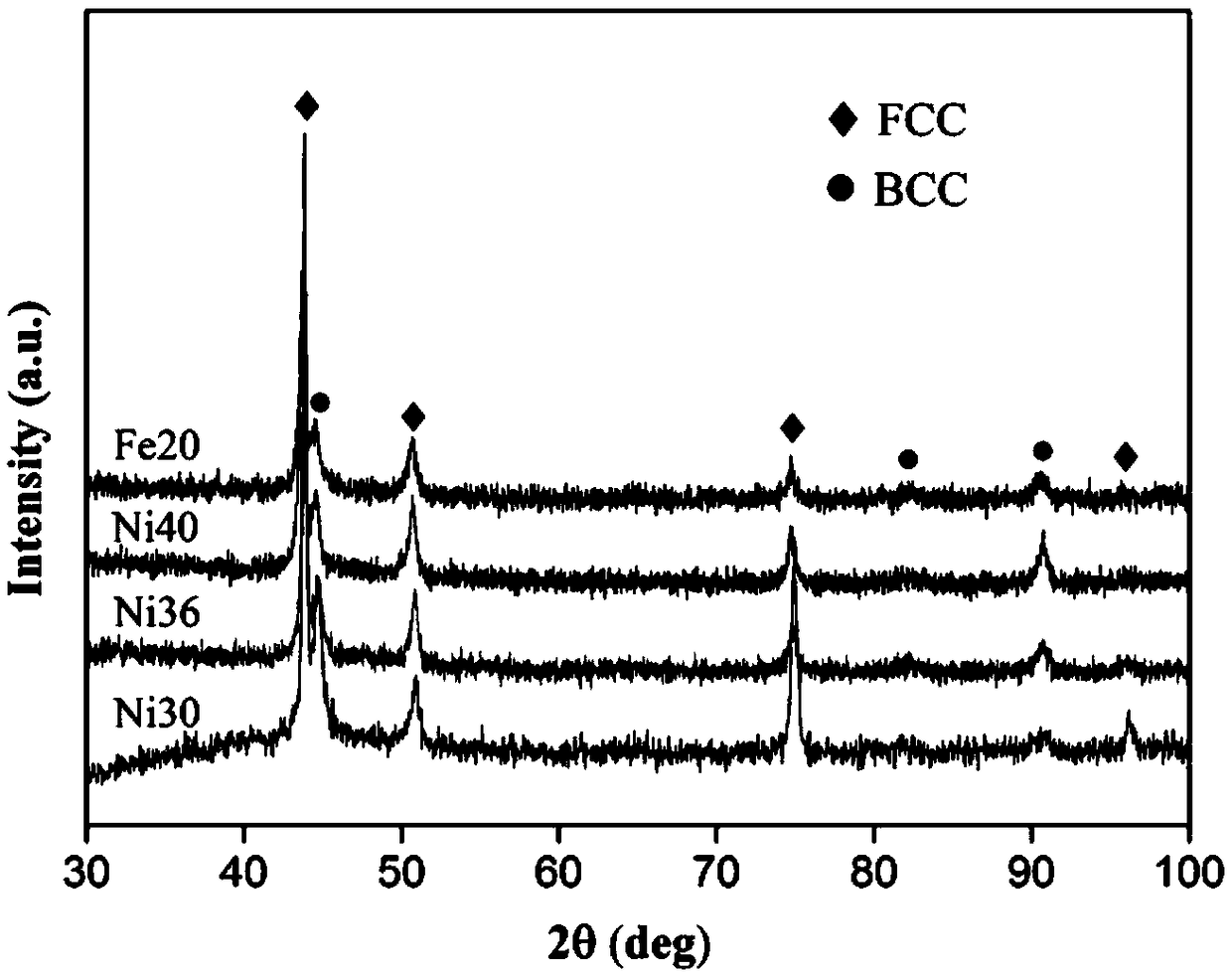

[0024] A high-strength and high-plastic eutectic high-entropy alloy, the chemical formula of which is Ni 30 co 30 Fe 10 Cr 10 al 18 W 2 , abbreviated as Ni 30 ; Wherein, the ratio of each element is mole percent.

[0025] A kind of Ni 30 co 30 Fe 10 Cr 10 al 18 W 2 The preparation method of eutectic high-entropy alloy comprises the following steps:

[0026] S1. Ultrasonic cleaning: the Ni, Co, Fe, Cr, Al, W alloy raw materials are mechanically ground to remove oxide scales on the surface of the elements, then placed in different containers and added with alcohol solution, ultrasonically cleaned, and dried after taking out the alcohol to obtain Six raw materials after ultrasonic treatment;

[0027] S2. Ingredients: Weigh 12.89g of Ni, 12.95g of Co, 4.10g of Fe, 3.81g of Cr, 3.56g of Al and 2.69g of W metal raw materials obtained in S1 according to the molar percentage of the eutectic high-entropy alloy and mixed;

[0028] S3: Master alloy smelting: Put the raw ma...

Embodiment 2

[0031] A high-strength and high-plastic eutectic high-entropy alloy, the chemical formula of which is Ni 36 co 24 Fe 10 Cr 10 al 18 W 2 , abbreviated as Ni 36 ; Wherein, the ratio of each element is mole percent.

[0032] The eutectic high-entropy alloy Ni 36 The preparation method is the same as that of Example 1, except that what weighed in S2 is 15.48g of Ni, 10.36g of Co, 4.10g of Fe, 3.81g of Cr, 3.56g of Al and 2.69g of W Metal raw materials.

Embodiment 3

[0034] A high-strength and high-plastic eutectic high-entropy alloy, the chemical formula of which is Ni 40 co 20 Fe 10 Cr 10 al 18 W 2 , abbreviated as Ni 40 ; Wherein, the ratio of each element is mole percent.

[0035] The eutectic high-entropy alloy Ni 40The preparation method is the same as the preparation method of Example 1, except that what weighed in S2 is 17.20g of Ni, 8.63g of Co, 4.10g of Fe, 3.81g of Cr, 3.56g of Al and 2.69g of W Metal raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

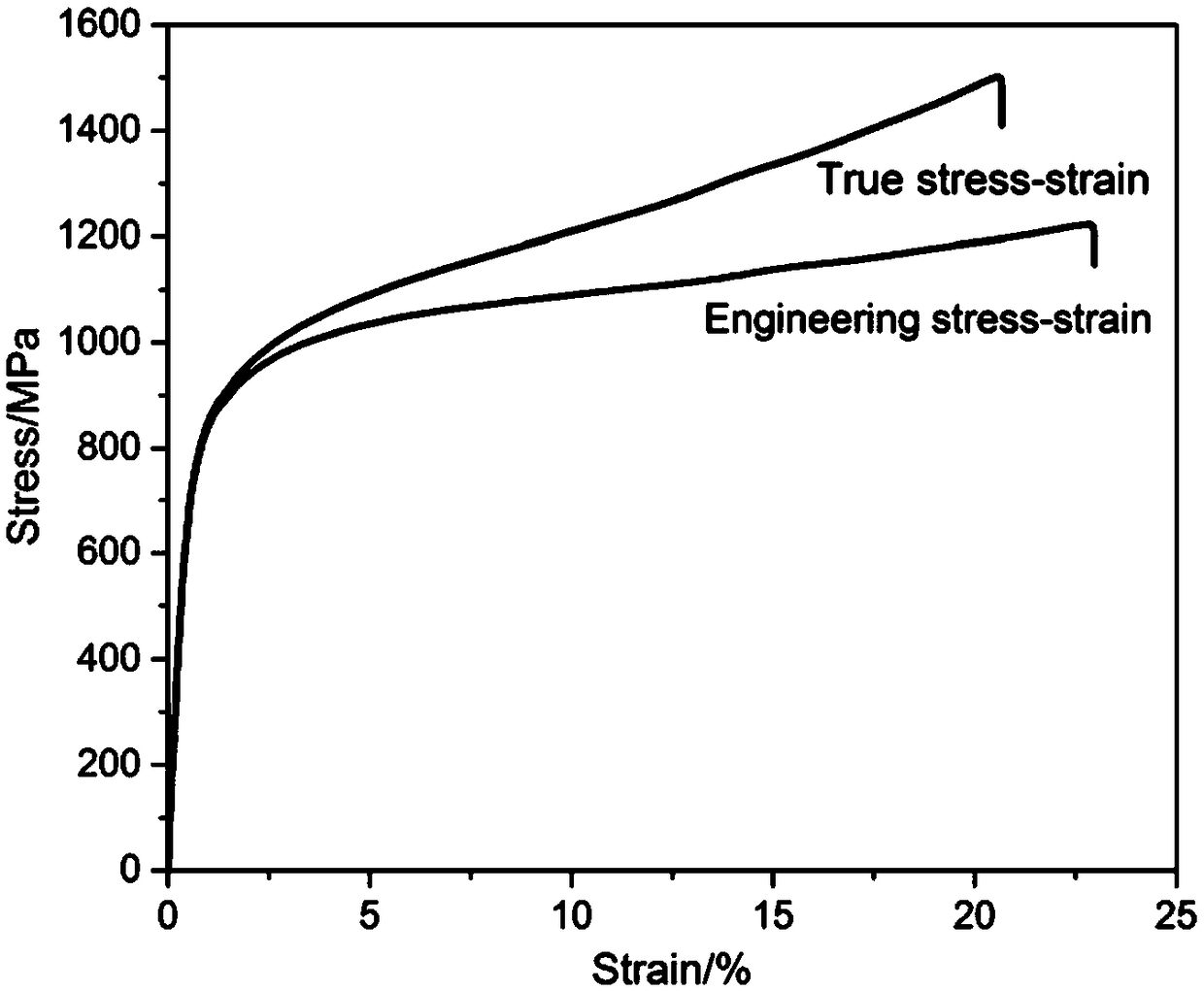

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com