Broaching method and special tool for high-accuracy small-sized mortises

A high-precision, small-sized technology, applied in the broaching of small-sized tongue and groove, the broaching method of high-precision small-sized tongue and groove and its special tool, and the high-precision field of disc parts, which can solve the problems of high processing difficulty and influence. Machining quality and broach life, broach chipping and chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

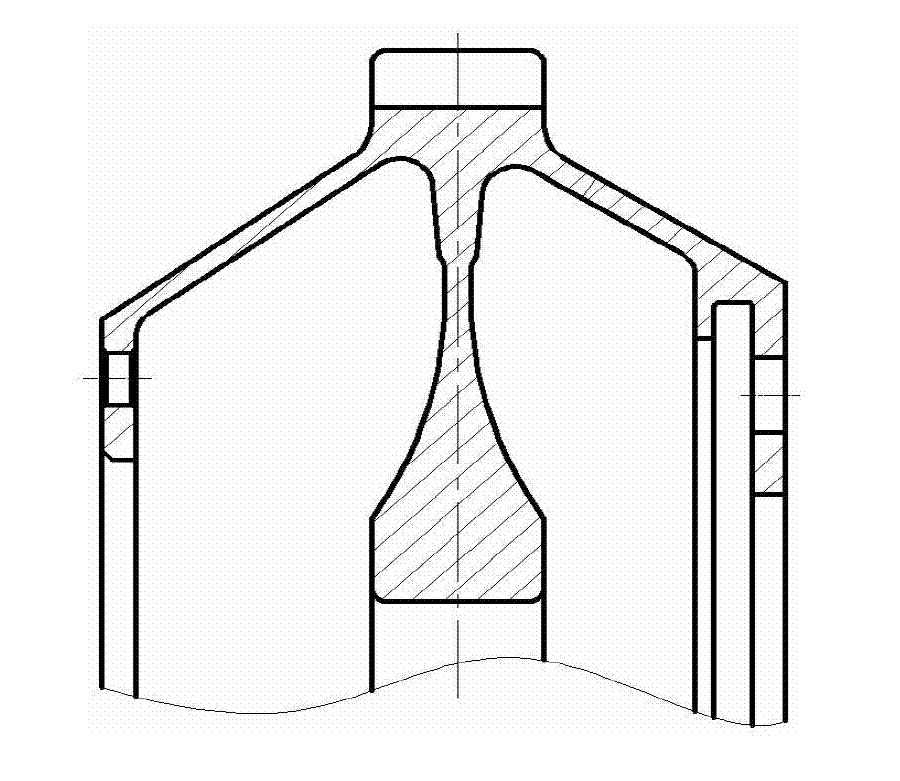

[0083] A special tool for the broaching method of high-precision small-sized tongue and groove, the special tool is a broach, and its structure meets the following requirements: the tooth tip of the broach is provided with straight chamfers or / and rounded chamfers that can participate in broaching .

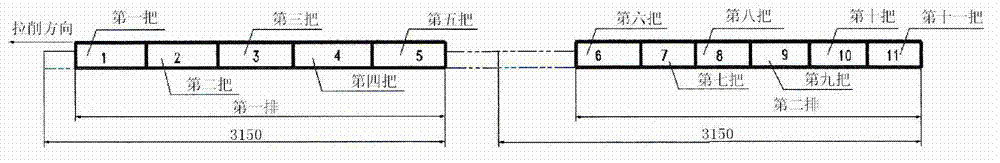

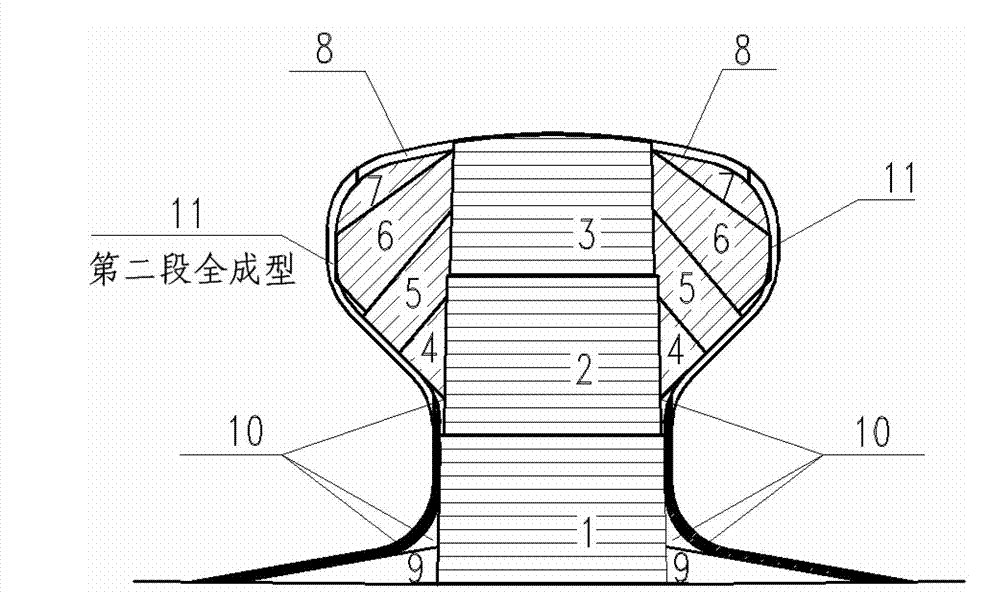

[0084] There are 11 forming broaches in the whole set; Among them: the 1st to 3rd broaches are coarse grooving knives, with 45° chamfers on the top and both sides of the tooth, forming a 45° side cutting edge, which can be involved with the tooth top edge at the same time Cutting; the 4th to 7th broach tooth-shaped grooving knives are all side oblique broaching methods, and the side edge is the main cutting edge; the 8th broach groove bottom R knife, the top of the tooth and both sides are transferred to the fillet R1 .5 is the main cutting, which is used to complete the broaching of the groove bottom profile; the 9th broach for the rough surface of the notch, the 10th broach for...

Embodiment 2

[0103] A broaching method for high-precision and small-sized mortise and groove: use a special broach to process the workpiece; the special broach structure meets the following requirements: the tooth top of the broach is equipped with a straight Chamfers and / or fillets;

[0104] The method for broaching the high-precision and small-sized tongue and groove meets the following requirements:

[0105] The removal method of broaching allowance is: use the main cutting edge of the tooth top of the broach or / and the chamfering part of the broaching tool, and the chamfering part of the broaching tool is the straight chamfering or / and rounding on both sides of the tooth top cutting edge Chamfer;

[0106] A complete set of 11 forming broaches are used in order to complete the entire contour shape of the tongue and groove; among them: the 1st to 3rd broaches are rough slotting knives, with 45° chamfers on the tooth top and both sides, forming a 45° The side cutting edge participates i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com