Numerical control machine for contour broach of internal screw of constant-wall-thickness stator and use method

A technology of forming broaching and CNC machine tools, which is applied in the field of CNC machine tools, can solve problems such as inability to solve parts manufacturing problems, fail to meet processing technical requirements, etc., and achieve the effect of expanding production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

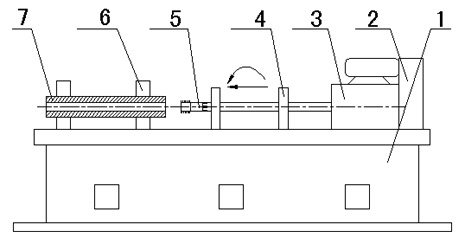

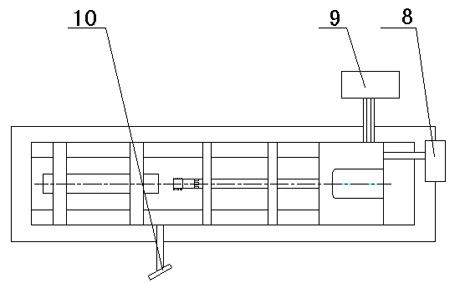

[0021] combined with Figure 1-3 , to further describe the present invention:

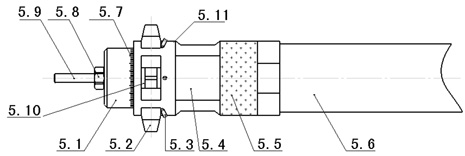

[0022] The CNC machine tool of the present invention is mainly composed of a bed 1, a push-pull system 2, a rotation system 3, a tool system 5, a hydraulic system 8, an electrical control cabinet 9, and a control system 10. The top of the bed 1 is sequentially installed with a hydraulic system 8 from one side. , push-pull system 2, rotating system 3, tool system 5, the other side is provided with workpiece positioning fixture 6, it is characterized in that: described tool system 5 mainly is made up of blade 5.2, cutter body 5.11 and cutter bar 5.6, and cutter body The 5.11 is provided with a chip pocket 5.4 for holding chips cut by the tool, and the front part of the chip pocket 5.4 is a clamping slot for the blade, which is used for the installation and adjustment of the blade 5.2, and a metal brush is provided on the cutter body 5.11 5.5, with the rotation of the cutter bar, the chips are cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com